Chicken breast pickling device

A technology for chicken breast and meat pieces, which is applied in the fields of food forming, food science, and application, can solve the problems of slow meat marinating efficiency, and achieve the effect of accelerating the speed of diffusion, reasonable design, and speeding up efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

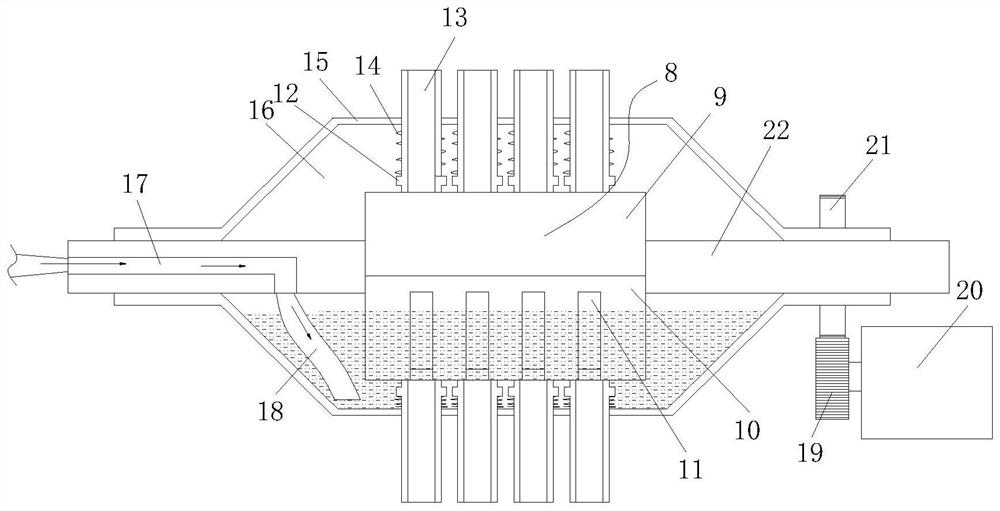

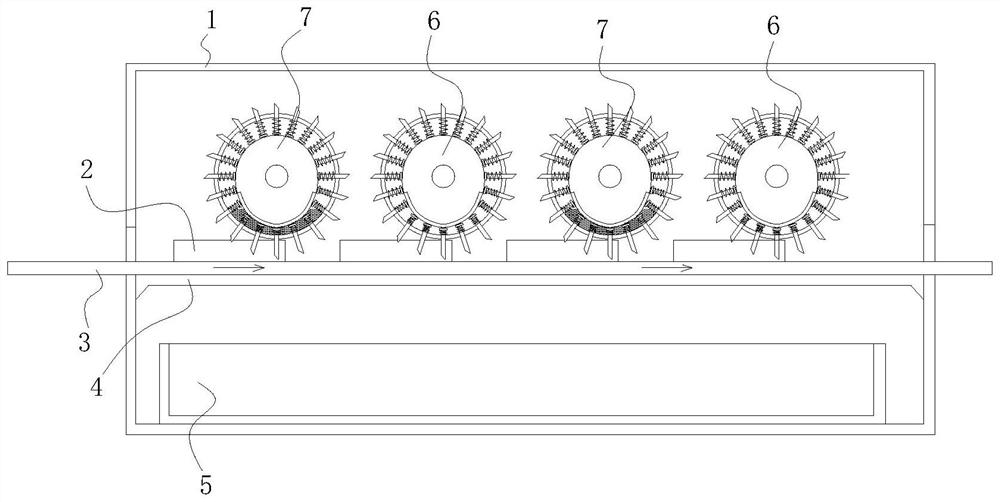

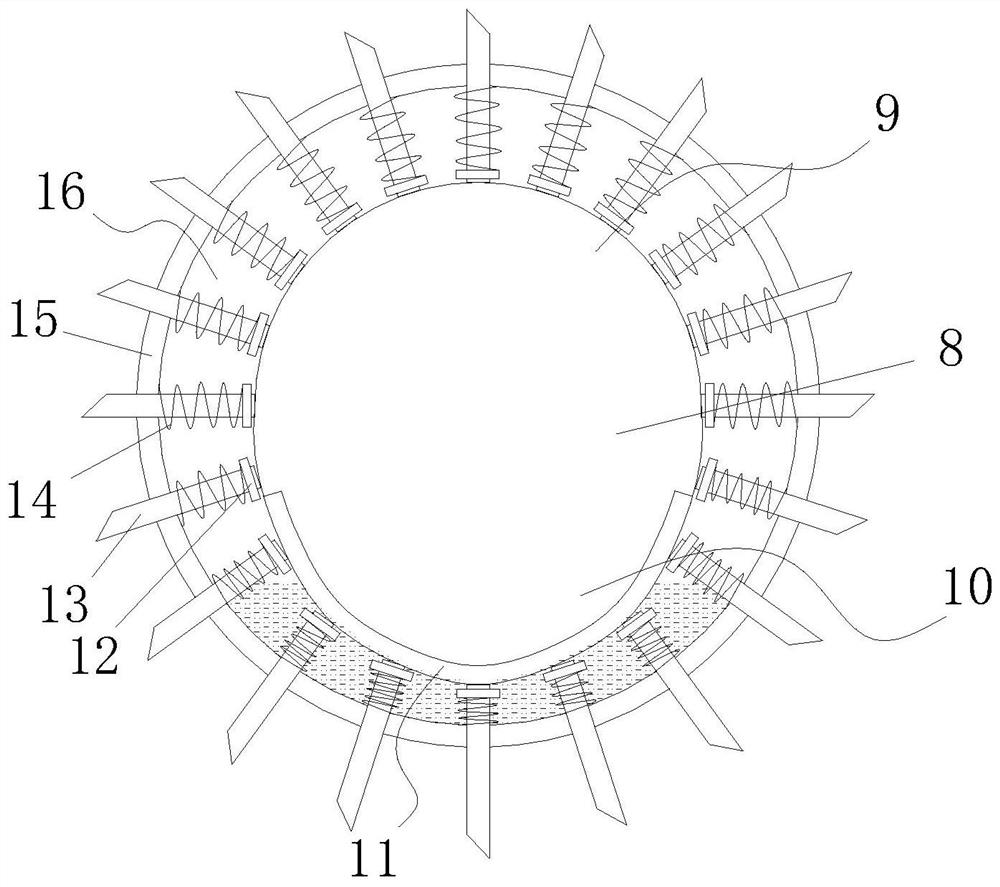

[0024] refer to Figure 1-6 , a chicken breast marinating device, including a frame, a conveyor belt 3 for transporting meat pieces 2, a support plate 4 is provided at the bottom of the conveyor belt 3, and several conveyor belts are provided above the conveyor belt 3 for injecting the marinade liquid into the meat. The positive pressure liquid filling mechanism 7 inside the block, the top of the conveyor belt 3 is provided with several negative pressure suction mechanisms 6 for sucking the marinade liquid inside the meat block outwards, and the positive pressure liquid filling mechanism 7 is for the meat block. The suction port of the injection port and the negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com