Material falling type hand bag packaging machine

A technology for handbags and packaging machines, applied in packaging, transportation packaging, packaging protection and other directions, can solve the problems of cumbersome adjustment of replacement specifications, poor operation stability, unstable packaging effect, etc., to achieve stable and efficient work, easy adjustment, and packaging. good bag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

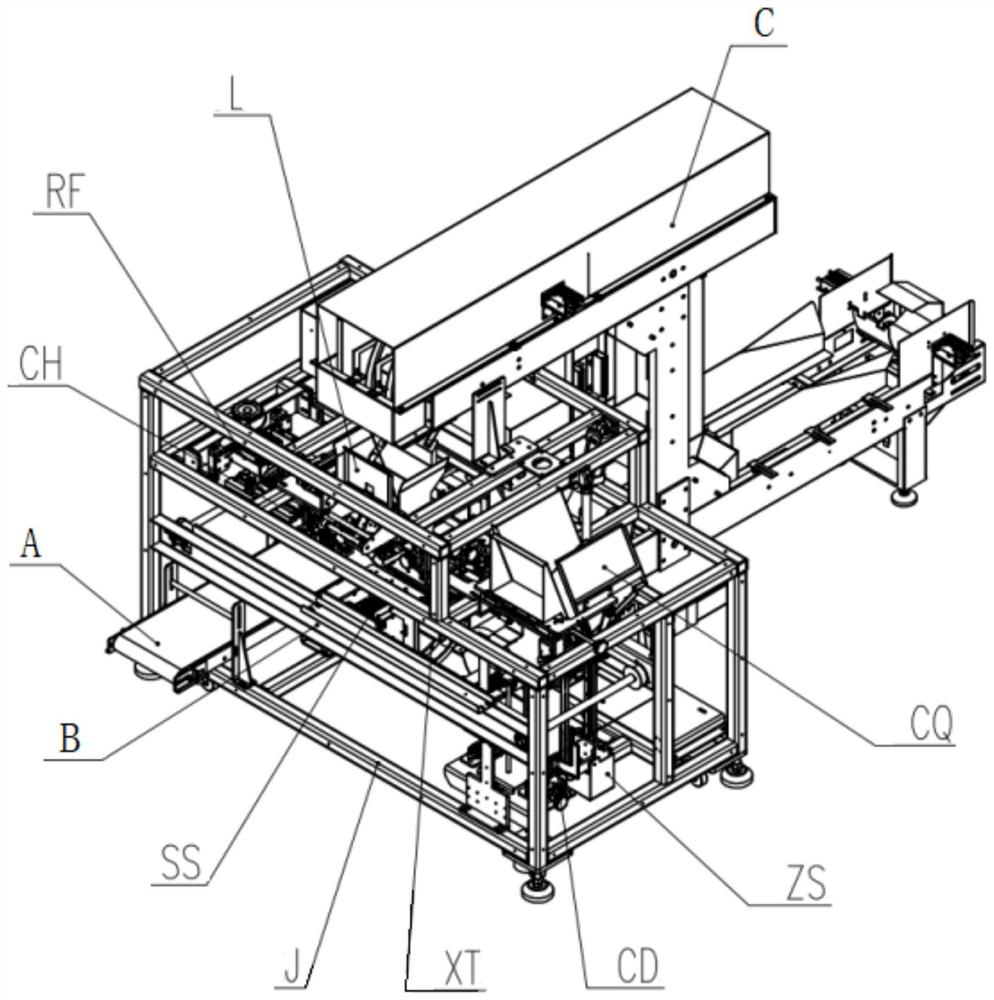

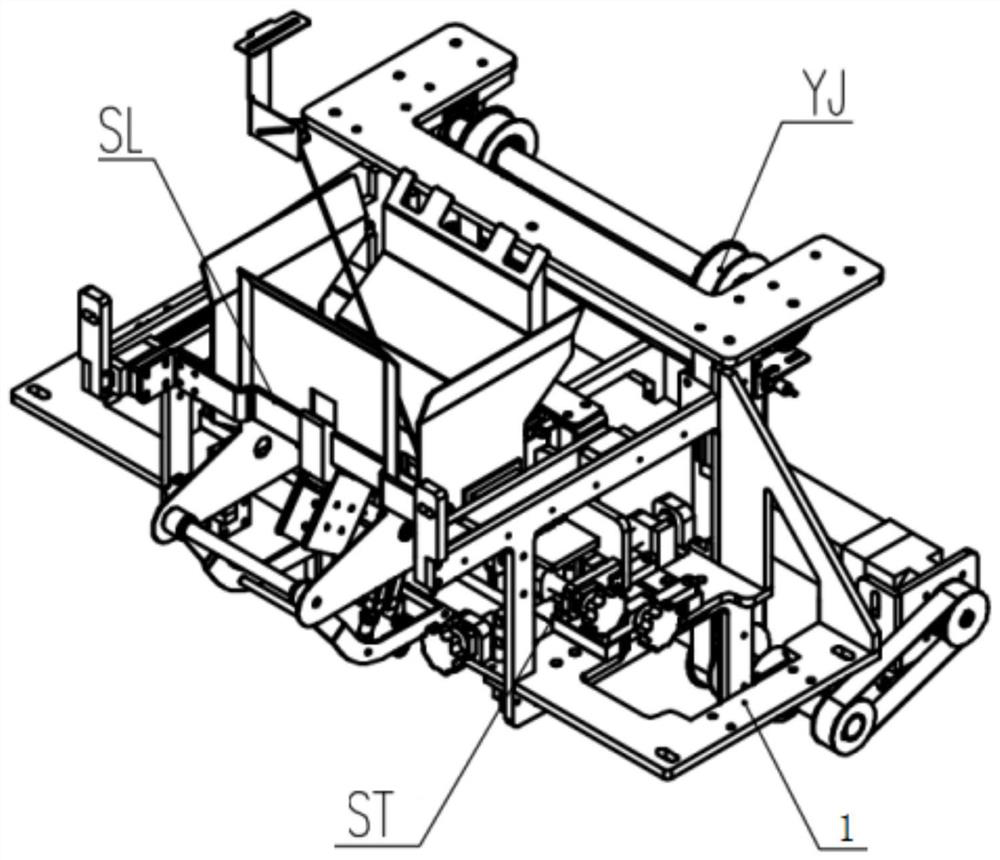

[0035] See figure 1 , Blanking present invention provides a bag-type packaging machine, comprising: a bolted blanking means L, pouch means take the bag on the frame structure of the J CQ, grasping the bag the bag feeding mechanism ZS, storage bags bags stop mechanism CD , support means bags sealed bags CH, duplex feeding mechanism SS, and the rotation of the holder surface blanching sealing mechanism XT mechanism RF, L blanking means integrally mounted in the upper portion of the J frame structure, which is above the outlet of the lift C corresponding (action "hoist C" is mainly to provide good noodles and other materials have been weighed, not part of the patent for this packaging machine); support means CH bags sealed bags mounted immediately below the blanking means is L; the support below bags sealable bags mechanism CH is mounted duplex feeding mechanism of the SS; pouch take bags mechanism CQ mounted on the left blanking mechanism L; and grip the bag feeding bags mechanism Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com