Optical glass

An optical glass and quality technology, applied in the field of optical glass, can solve the problems of easy deterioration of molds and unoptimized mold durability, and achieve the effects of high water resistance, low glass transition point, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

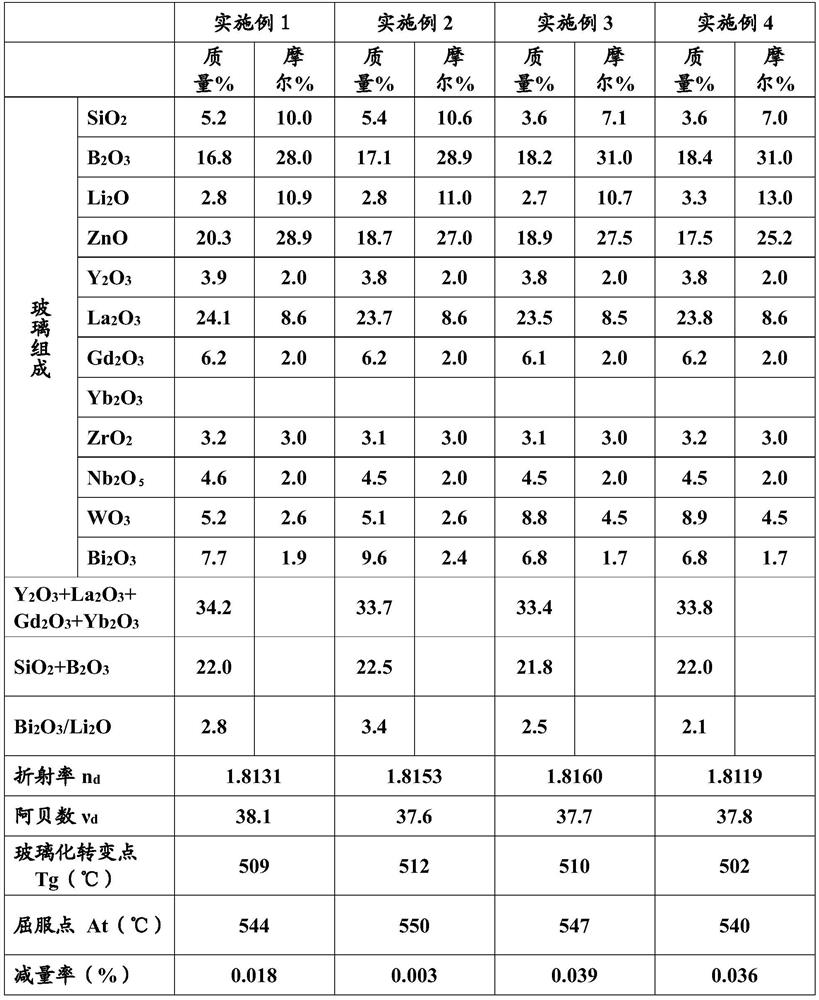

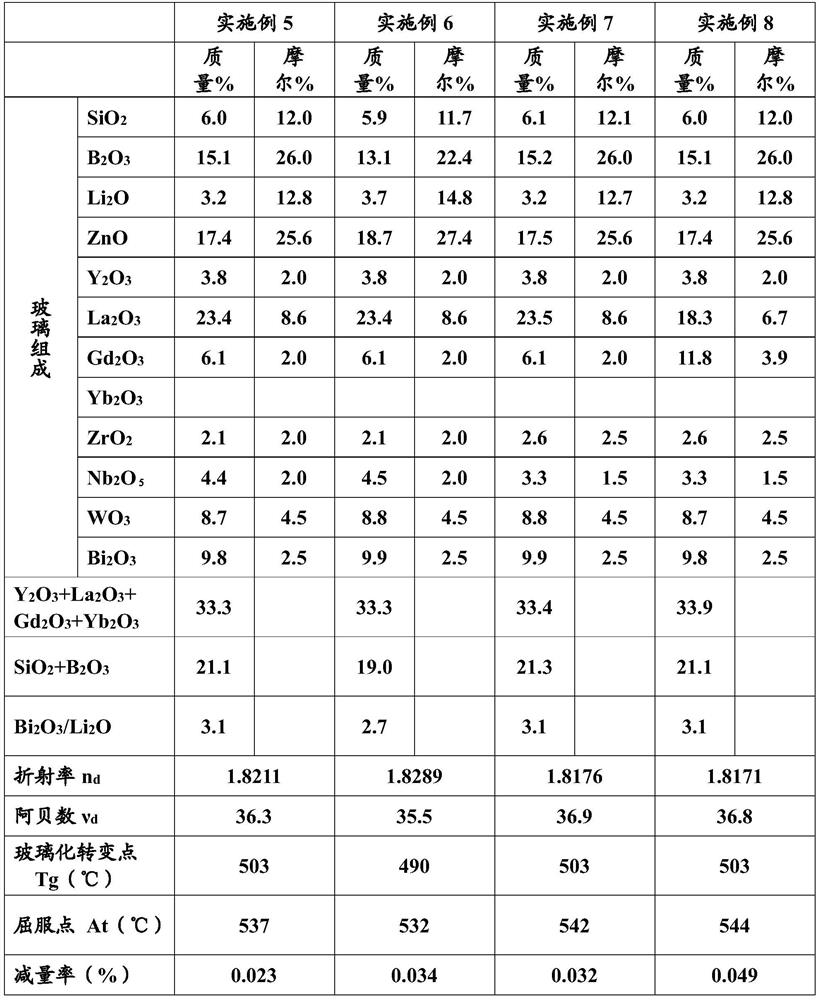

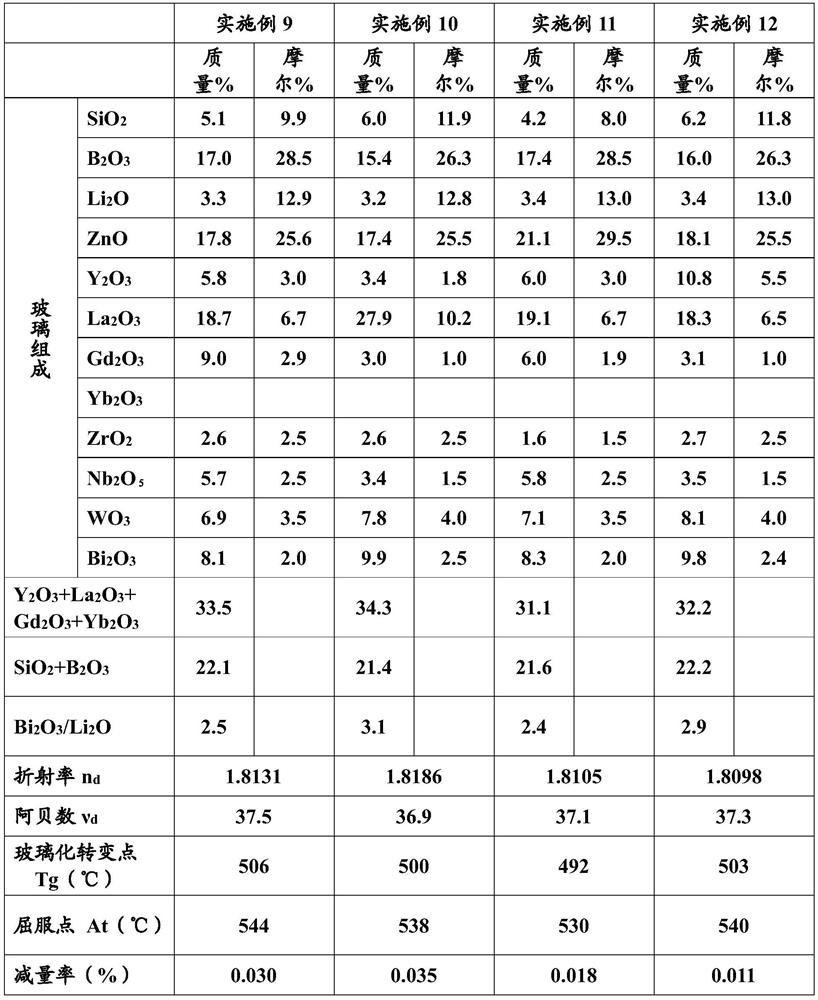

[0106] Hereinafter, the present invention will be further described with reference to examples. The present invention is not limited by these Examples.

[0107]The raw materials were prepared and mixed so as to have the composition of Examples 1 to 14 and Comparative Examples 1 to 4 shown in Tables 1 to 5, put into a platinum crucible, and melted in an electric furnace at 1200 to 1300° C. After clarification (degassing) and stirring, the temperature was lowered to 1000 to 1100° C., and then poured into a mold and slowly cooled to obtain optical glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com