Method for monitoring pneumatic unbalance of fan blades

A wind turbine blade and balancing technology, applied in wind turbine monitoring, wind turbines, machines/engines, etc., can solve problems such as reduction of wind turbine power generation, increase of wind turbine periodic load, and difficulty in selecting reliable comparison and analysis of similar working conditions. , to achieve the effect of reducing power generation and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples, but the usage of the present invention is not limited thereto.

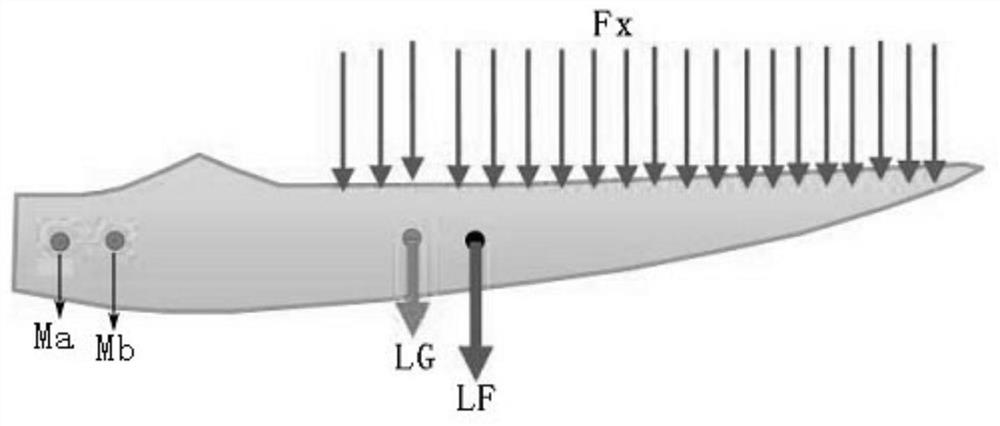

[0028] In the method for monitoring the aerodynamic unbalance of fan blades described in this embodiment, first, two installation points a and b are selected at the root region of each blade of the fan, such as figure 1 As shown, let the distances between the two installation points and the starting point of the blade root be LMa and LMb respectively, let the loads at the two installation points be Ma and Mb respectively, let the gravity of the blade be G, the center of gravity be LG, and the aerodynamic force be Fx , the aerodynamic moment is LF;

[0029] According to the balance formula of moment:

[0030] Ma=G×(LG-LMa)×f(θ)+Fx(LF-LMa) (2)

[0031] Mb=G×(LG-LMb)×f(θ)+Fx(LF-LMb) (3)

[0032] In the formula, f(θ) is the gravity component function of the blade azimuth angle, where the azimuth angles of the three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com