Special wire fixing frame for combined side surface

A wire-fixing and card-fixing technology, applied in the direction of electrical components, can solve problems such as high technical requirements and lack of any auxiliary tools, so as to achieve the effects of improving safety performance, improving construction quality and progress, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

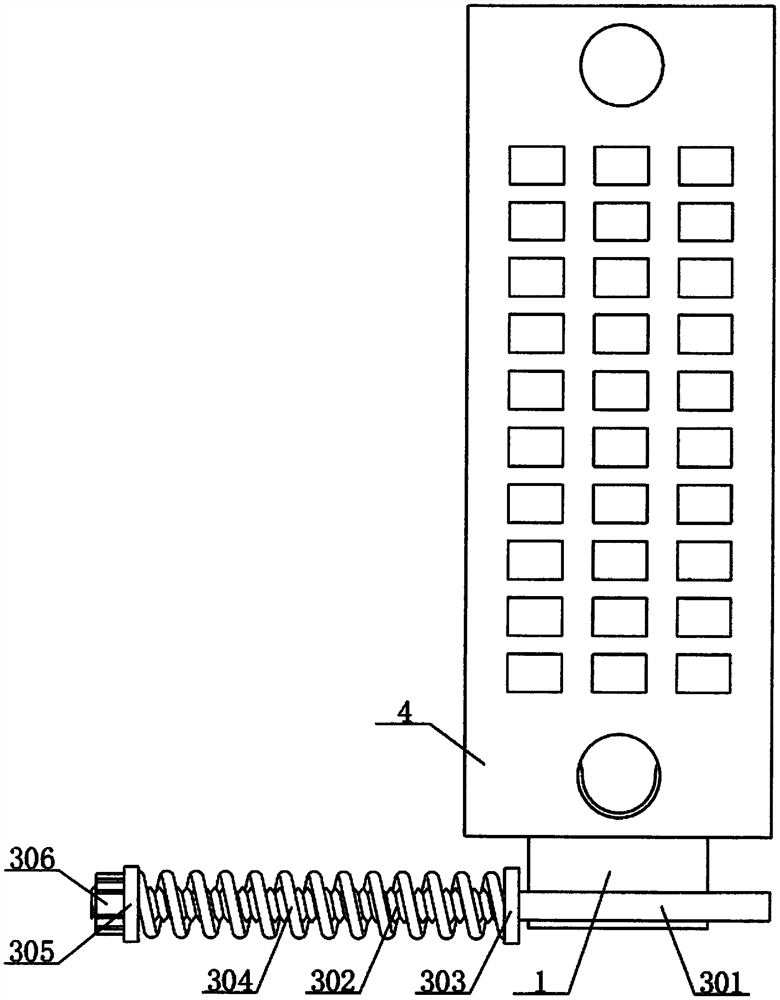

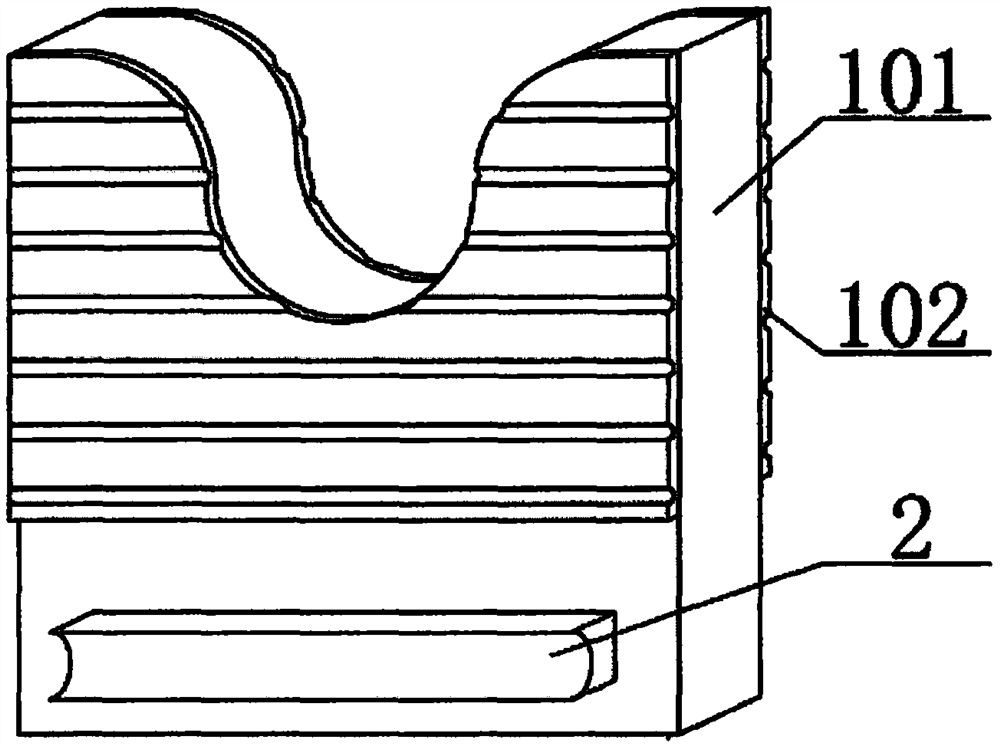

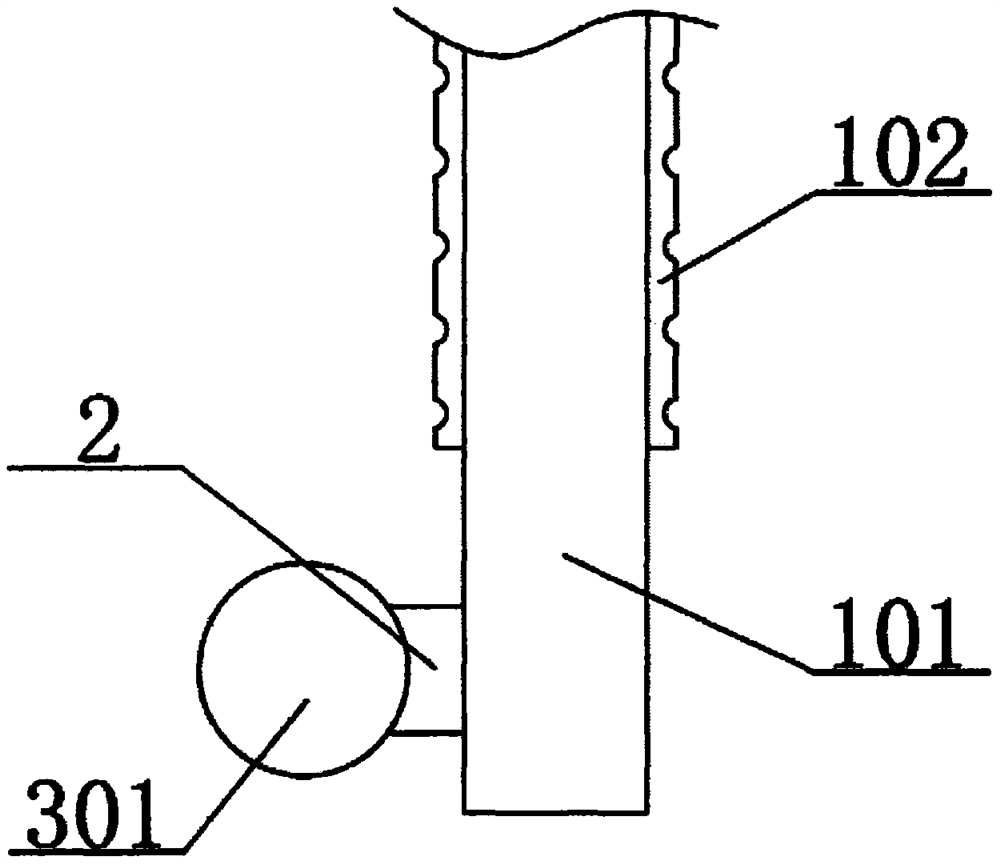

[0020] see figure 1 , figure 2 , image 3 with Figure 4 , the present invention provides a technical solution:

[0021] A wire fixing frame dedicated to combined sides, comprising a fixing device 1, a fixing block 2, a winding device 3 and a lug terminal block 4, the fixing device 1 is arranged on the bottom side of the rear end surface of the lug terminal block 4, and the fixing The device 1 includes a fixed clamping plate 101, a left top plate 103 and a right top plate 104, the bottom side of the front end of the fixed clamping plate 101 in the fixing device 1 is fixedly connected with a fixed block 2, and the outer end surface of the fixed block 2 is fixedly connected with a winding line device3.

[0022] The inner side of the top of the fixed clamping plate 101 is provided with a U-shaped clamping groove, and the U-shaped clamping groove in the fixed clamping plate 101 is aligned with the screw hole on the inner side of the solder lug terminal block 4, so that the fi...

Embodiment 2

[0025] see figure 1 , figure 2 , image 3 with Figure 5 , the present invention provides a technical solution:

[0026] A special wire fixing frame for combined side, a special wire fixing frame for combined side, including a fixing device 1, a fixing block 2, a winding device 3 and a soldering lug terminal block 4, the fixing device 1 is arranged on the soldering lug terminal block 4 The bottom side of the rear end surface of the fixed device 1 includes a fixed clamping plate 101, a left top plate 103 and a right top plate 104. The bottom side of the front end surface of the fixed clamping plate 101 in the fixed device 1 is fixedly connected with a fixed block 2. A winding device 3 is fixedly connected to the outer end surface of the block 2 .

[0027]The inner side of the top of the fixed clamping plate 101 is provided with a U-shaped clamping groove, and the U-shaped clamping groove in the fixed clamping plate 101 is aligned with the screw hole on the inner side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com