Underground latex paint spraying device

A technology of spraying device and latex paint, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of low utilization rate of paint, uneven paint thickness, difficult to use underground environment, etc., to achieve convenient operation, high painting efficiency and maintenance. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

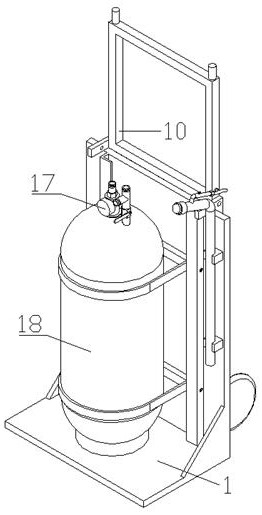

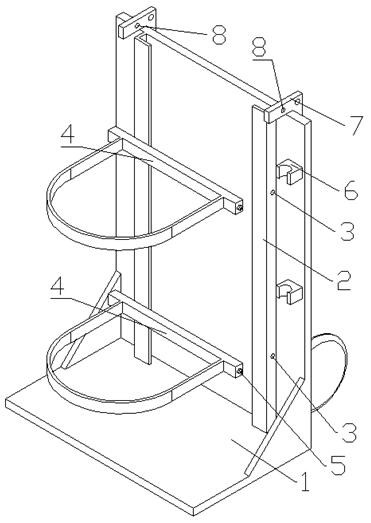

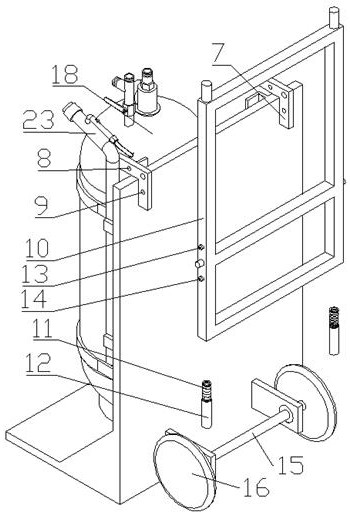

[0015] Such as Figure 1-4 Shown, a kind of downhole latex paint spraying device comprises vehicle frame 1, mounting rail 2, front limit hole 3, limit frame 4, front spring pin 5, support buckle 6, support plate 7, upper limit hole 8, rear Limit hole 9, support frame 10, buffer spring 11, support column 12, upper spring pin 13, rear spring pin 14, support shaft 15, roller 16, painting part 17, described vehicle frame 1 front end left and right sides respectively are fixed with Mounting rails 2, the upper and lower parts of the two mounting rails 2 each run through a front limit hole 3, and two horizontal limit frames 4 are jointly slidably connected between the two mounting rails 2, in order to ensure that the two mounting rails 2 can work well The sliding connection with the limit frame 4 should ensure that the contact part is smooth and fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com