Auxiliary polishing device for intelligent fine production of rice

A polishing device, fine technology, applied in the direction of application, chemical instruments and methods, separating solids from solids with air flow, etc., to achieve the effects of avoiding large loads, improving screening effects, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

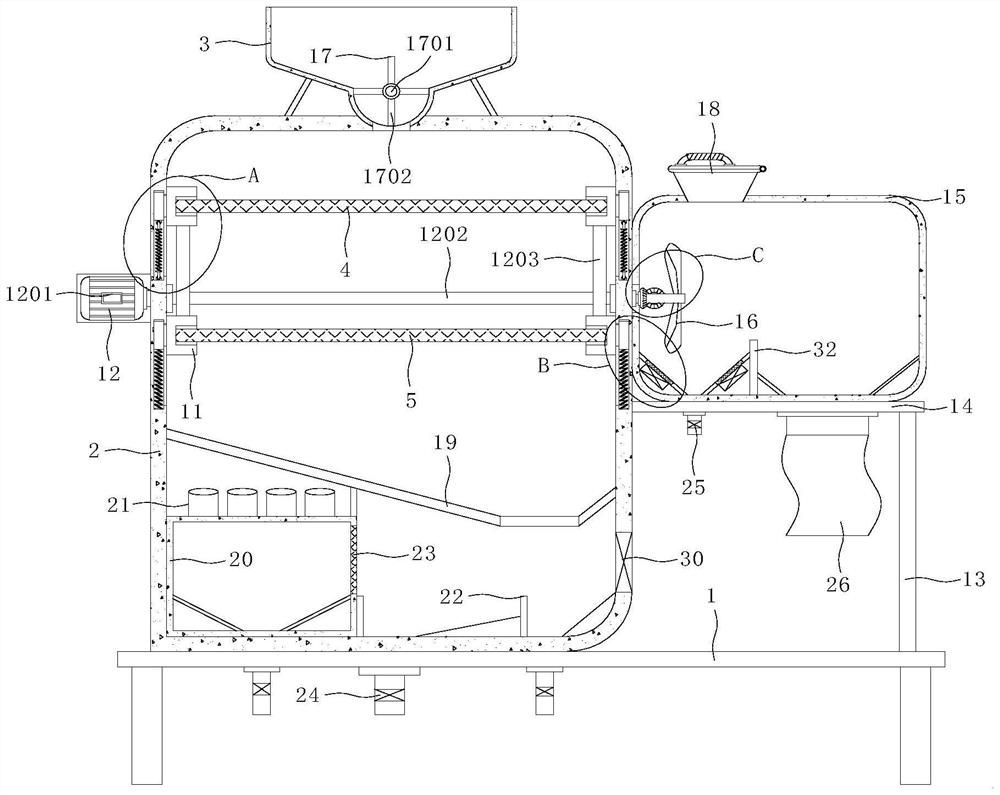

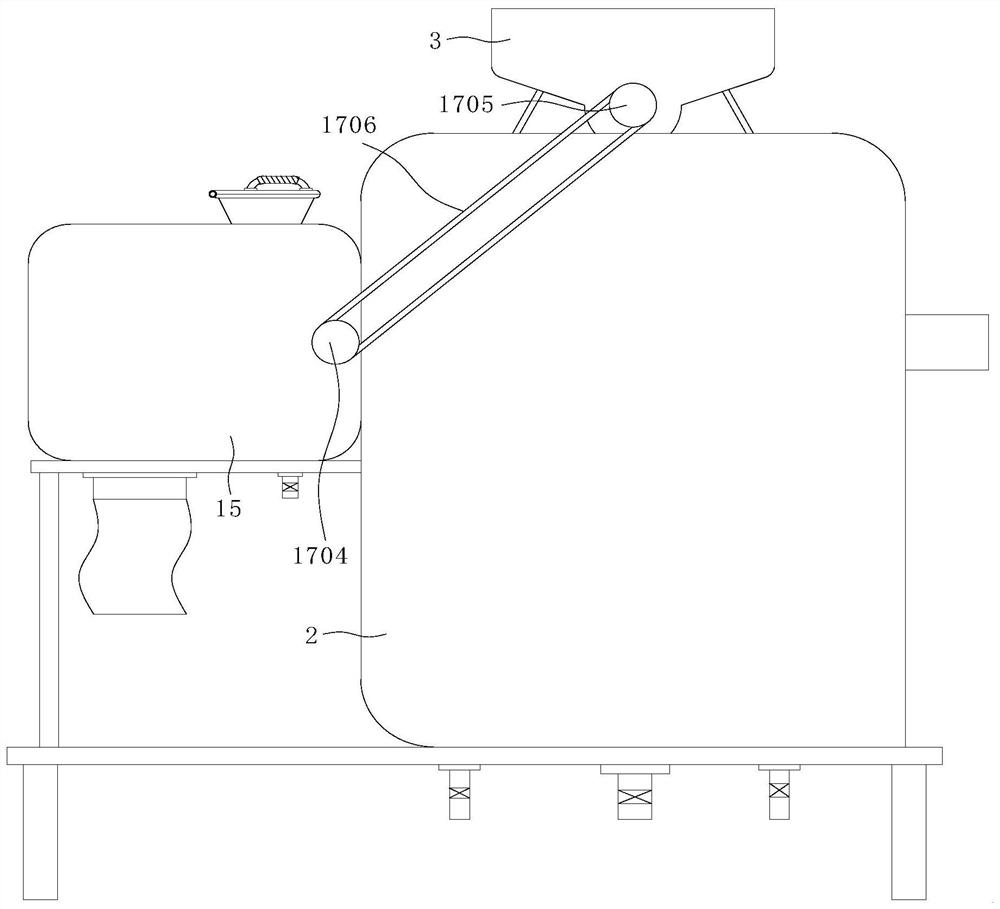

[0027] see Figure 1-7 , the present invention provides a technical solution: an auxiliary polishing device for intelligent and fine production of rice, comprising a bottom plate 1, a box body 2 is fixedly installed on the top of the bottom plate 1, a groove is opened on the top of the box body 2, and the groove A feeding box 3 is fixedly installed inside, and the bottom of the feeding box 3 is provided with a feeding port, the inside of the box body 2 is provided with a screen 4 and a magnetic screen 5, and the inside of the bottom plate 1 is fixedly installed with a blanking plate 19. A feeding port is provided on the material plate 19, an electrostatic precipitator box 20 and a partition 22 are fixedly installed on the inner bottom of the base plate 1, an electrostatic precipitator 21 is fixedly installed on the top of the electrostatic precipitator box 20, and an opening is provided on one side of the electrostatic precipitator box 20 , a filter screen 23 is fixedly instal...

Embodiment 2

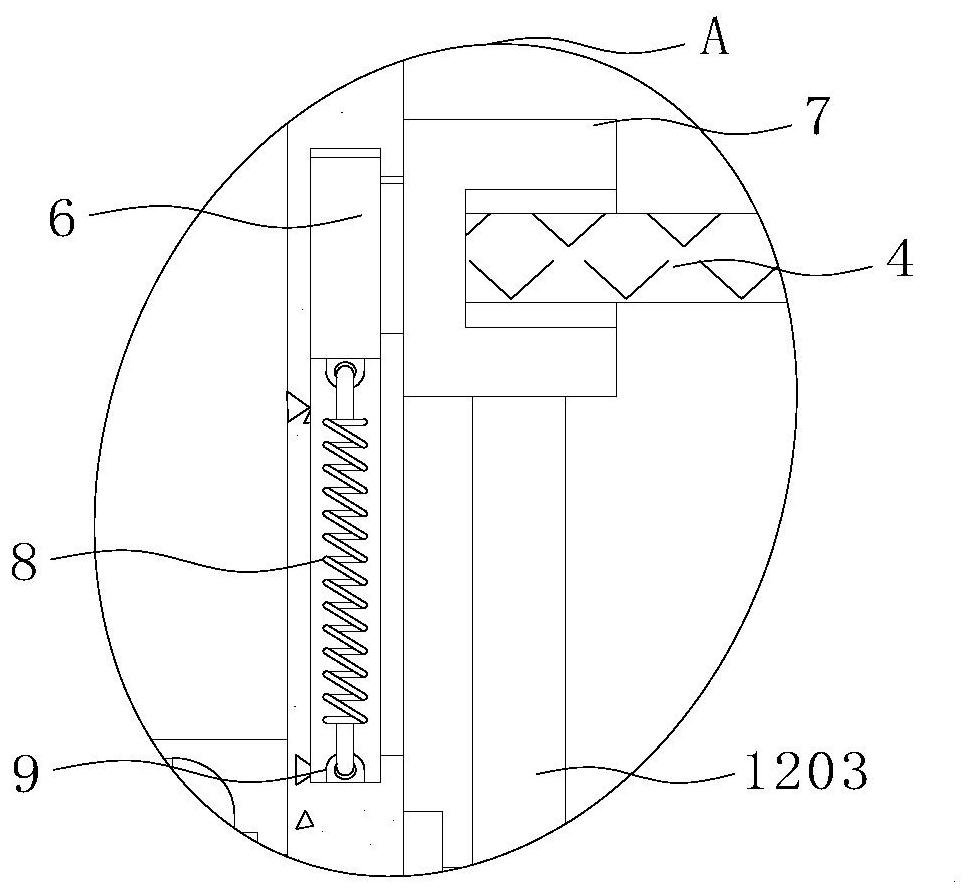

[0034] see Figure 1-7 , on the basis of Embodiment 1, the shaking mechanism 12 includes a motor 1201, a rotating rod 1202, a cam 1203 and a bevel gear 1204, and the other side of the box body 2 is fixedly installed with a horizontal block, and the front outer wall of the horizontal block is fixedly installed There is a motor 1201, a rotating rod 1202 is installed inside the casing 2, and a cam 1203 is fixedly installed on the outer wall of the rotating rod 1202, and the outer wall of the cam 1203 is in contact with the clamping block 7 and the clamping block 11 respectively to control the start of the motor 1201. The motor 1201 drives the rotation of the rotating rod 1202, and the rotating rod 1202 drives the rotation of the cam 1203, and then the screen 4 and the magnetic screen 5 are pushed by the clamp block 7 and the clamping block 11 to shake, so that the screen 4 and the magnetic screen 5 are easily shaken. 5. Shake at the same time to make it convenient to shake, scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com