Equipment overhaul stand convenient to clean for coal mechanical equipment

A technology for mechanical equipment and equipment maintenance, applied in the direction of liquid cleaning methods, separation methods, chemical instruments and methods, etc., can solve problems such as lack of integration of cleaning and maintenance, unsatisfactory drum cleaning effects, waste of water resources, etc., to achieve Save labor, save time, and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

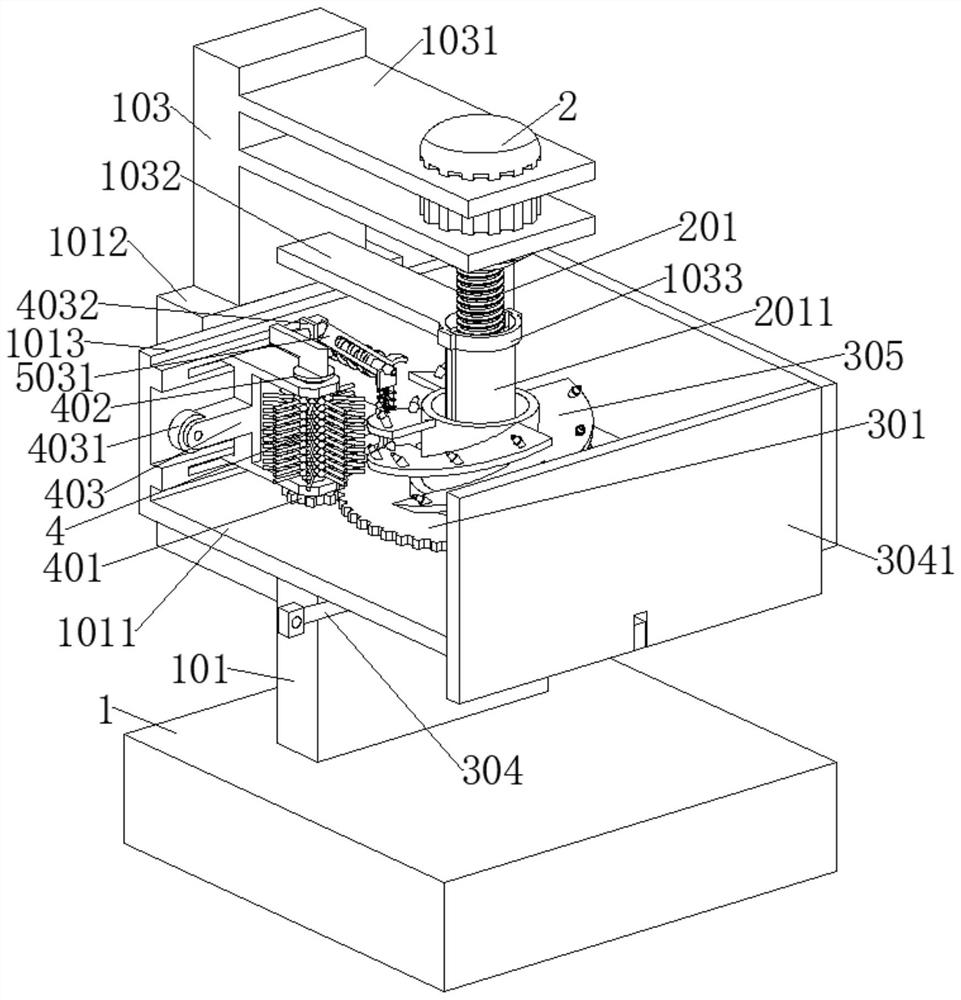

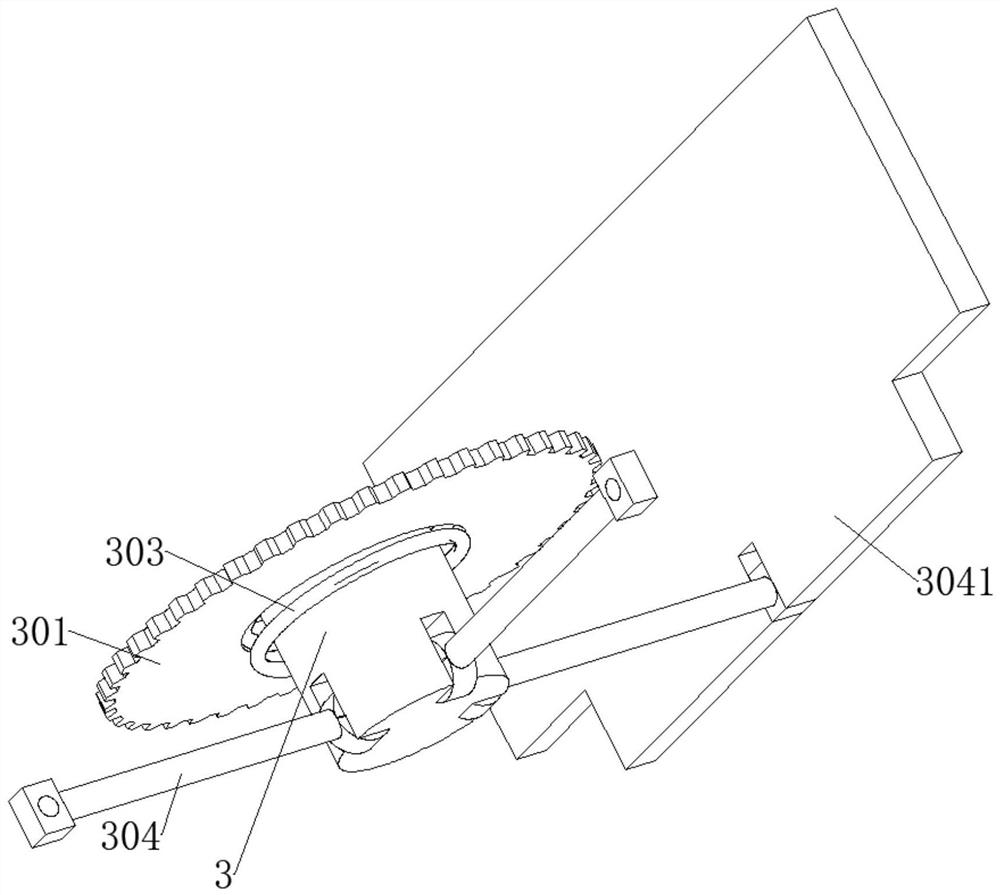

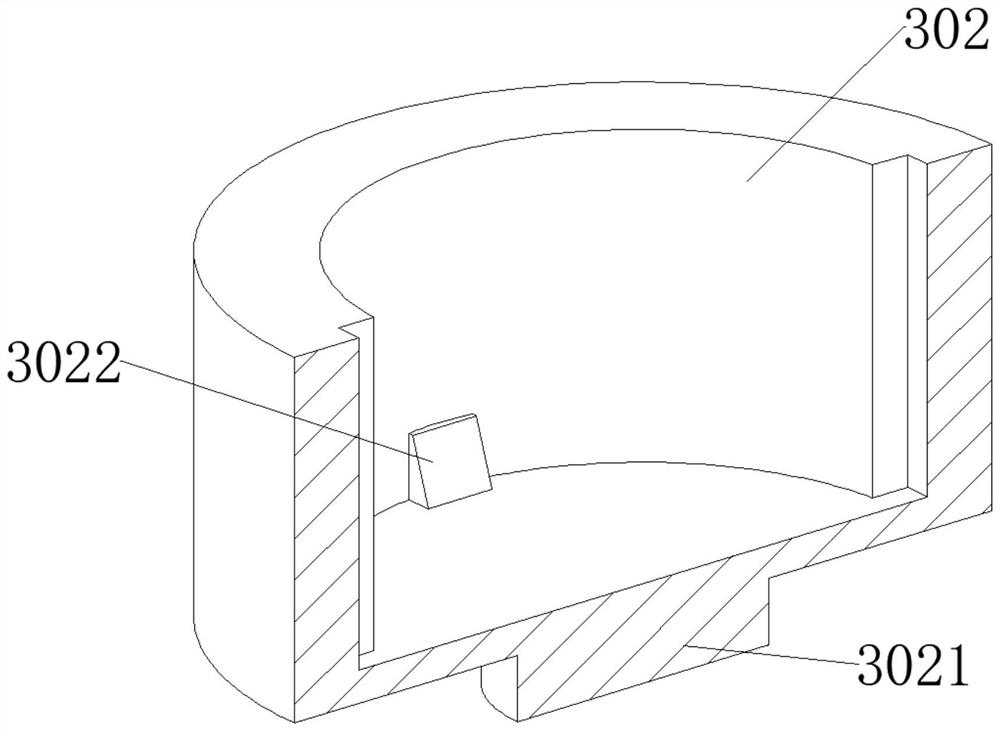

[0030] refer to Figure 1-7 , an equipment maintenance platform for coal machinery and equipment that is easy to clean, including a fixed seat 1 and a roller 305, the fixed seat 1 is fixedly connected with a support plate 101, and the support plate 101 is fixedly connected with a workbench 1011 and an L-shaped installation plate 1012. A back plate 1013 is fixedly connected to the table 1011, a gear door 3041 is rotatably connected to the workbench 1011, a placement column 3 is slidably connected to the workbench 1011, a mounting column 302 is rotatably connected to the placement column 3, and a mounting column 302 is fixedly connected to the mounting column 302. The first gear 301, the L-shaped mounting plate 1012 is provided with a driving part for driving the mounting column 302 to rotate, the roller 305 is sleeved on the mounting column 302, the bottom of the roller 305 is attached to the first gear 301, and the rear plate 1013 is provided with There is a nozzle 501, a drai...

Embodiment 2

[0045] refer to Figure 1-7 , an equipment maintenance platform for coal machinery and equipment that is easy to clean, including a fixed seat 1 and a roller 305, the fixed seat 1 is fixedly connected with a support plate 101, and the support plate 101 is fixedly connected with a workbench 1011 and an L-shaped installation plate 1012. A back plate 1013 is fixedly connected to the table 1011, a gear door 3041 is rotatably connected to the workbench 1011, a placement column 3 is slidably connected to the workbench 1011, a mounting column 302 is rotatably connected to the placement column 3, and a mounting column 302 is fixedly connected to the mounting column 302. The first gear 301, the L-shaped mounting plate 1012 is provided with a driving part for driving the mounting column 302 to rotate, the roller 305 is sleeved on the mounting column 302, the bottom of the roller 305 is attached to the first gear 301, and the rear plate 1013 is provided with There is a nozzle 501, a drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com