Fly ash mixing and removing system for garbage power plant

A power plant and fly ash technology, applied in the direction of smoke removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of heavy maintenance workload, reduced bag flowability, high construction cost, etc., to eliminate fugitive emissions , Reduce the amount of equipment maintenance and improve the effect of the workshop environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

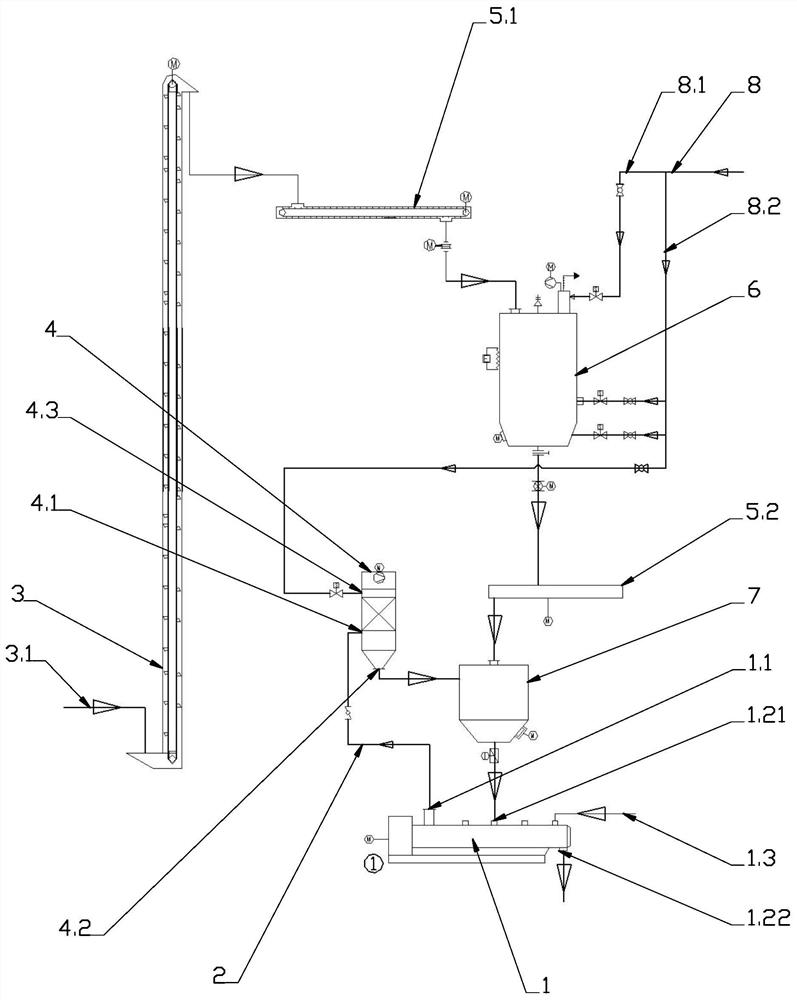

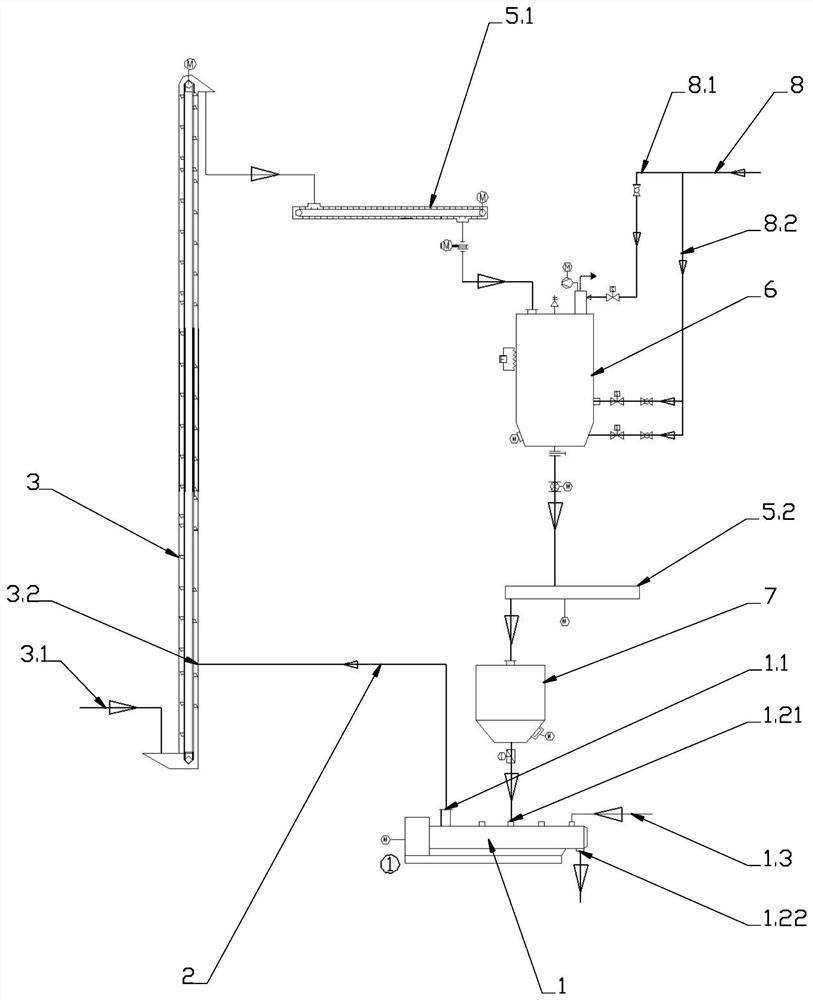

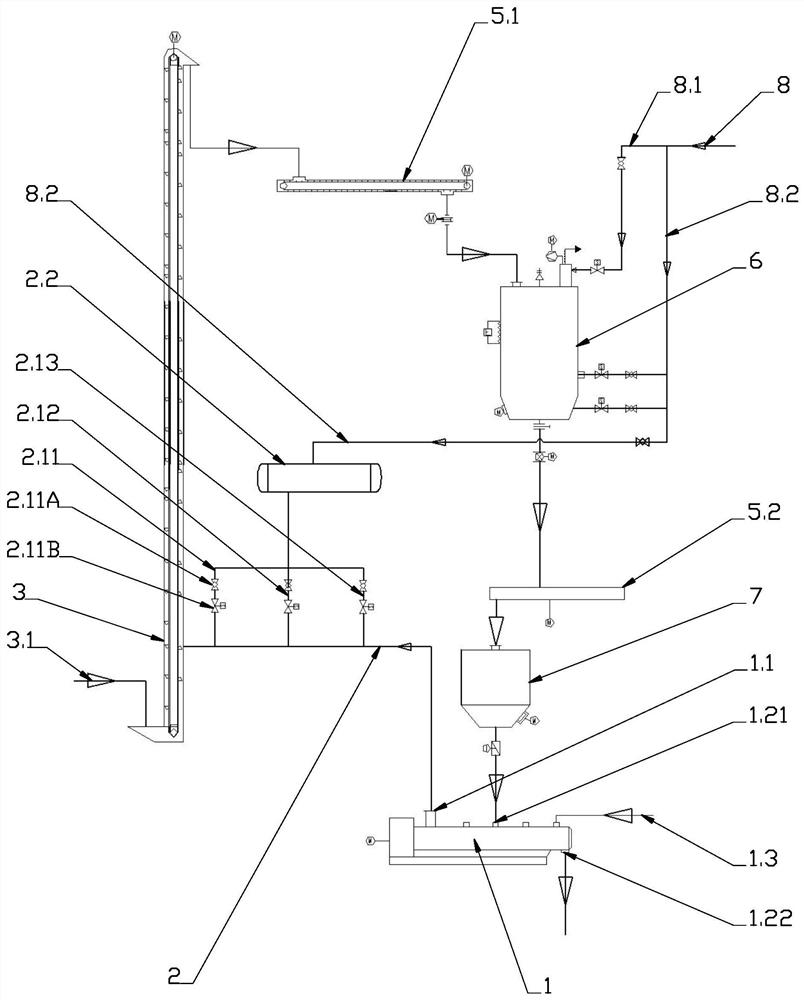

[0021] figure 1 It is a structural schematic diagram of an embodiment of the prior art. As shown in the figure, in the prior art, the fly ash of the garbage power plant enters the bucket elevator 3 through the fly ash conveying pipeline 3.1, and after being lifted by the bucket elevator 3, it is sequentially transported to the ash conveyor 5.1, the fly ash storage bin 6, and weighed The metering bin 7 then enters the mixer 1, and at the same time, the agent is added to the mixer 1 from the agent pipeline 1.3 to stabilize and mix the fly ash, and finally the ash is discharged from the ash discharge port 1.22 after mixing, and then filled after being packed. buried.

[0022] In the above-mentioned fly ash transportation and stabilization mixing process, the link that generates the most dust is the ash unloading and stirring of the mixer. As shown in the figure, the prior art uses the bag filter 4 to process the dust. The fly ash collected by the air outlet 1.1 of the mixing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com