Wire winch device for steel wire rope production and implementation method thereof

An implementation method and wire rope technology, which is applied in the field of wire winch devices for wire rope production, can solve problems such as wire looseness and bending, poor efficiency, front-end dredging, etc., and achieve the effects of preventing wire body shaking, improving stability, and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

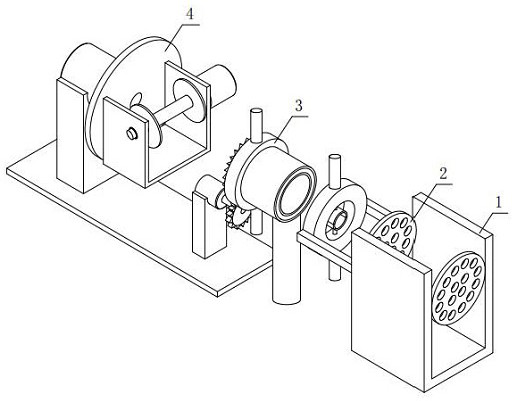

[0042] In order to better demonstrate the process of realizing the wire winch device for steel wire rope production, this embodiment proposes a method for implementing the wire winch device for steel wire rope production, including the following steps:

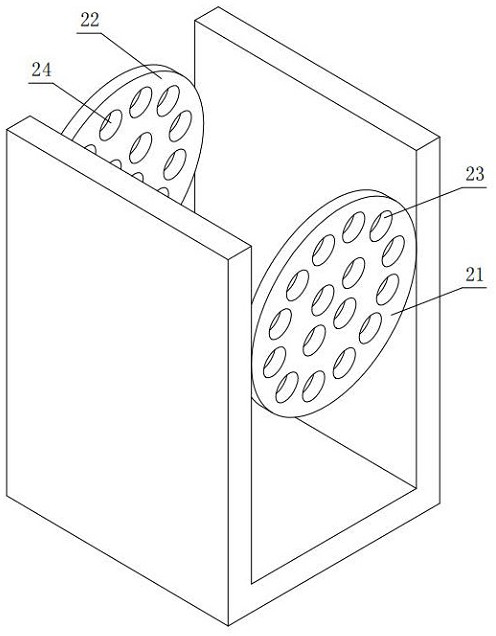

[0043] Step 1: After the silk thread penetrates through the front dredging hole 23 on the first dredging disc 21, it penetrates the rear dredging hole 24 of the second dredging disc 22, and is dredged by the first dredging disc 21 and the second dredging disc 22, and delivering the channeled wires into the holding strand assembly 3;

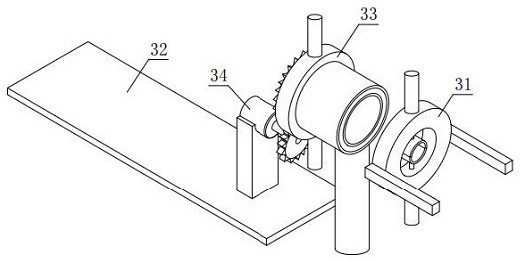

[0044] Step 2: The upper connection cylinder 313 and the lower connection cylinder 314 drive the upper clamping half-ring 315 and the lower clamping half-ring 316 to clamp, while clamping multiple groups of silk threads, the linkage assembly 34 drives the winch assembly 33 to rotate and fix the internal The silk thread is twisted;

[0045] Step 3: Adjust the motor 42 to drive the rotating disc 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com