Civil construction engineering structure gap grouting device

A technology of engineering structure and civil construction, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems of grouting treatment of gaps affecting the grouting machine, unevenness of the outer wall of the screw, slowing down of rotation speed, etc., so as to speed up the drop The effect of conveying speed, reducing impulse, reducing thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] as attached figure 1 To attach Image 6 Shown:

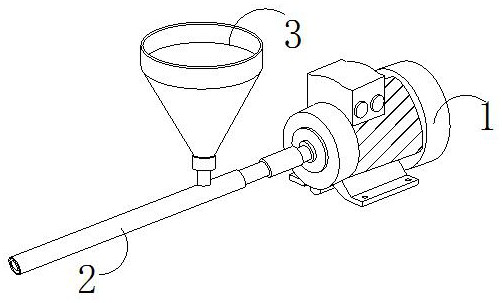

[0030] The present invention provides a gap grouting device for civil and construction engineering structures. The structure includes a motor 1, a feeding pipe 2, and a funnel 3. The right end of the feeding pipe 2 is horizontally connected to the middle part of the left end of the motor 1, and the bottom of the funnel 3 is installed vertically. On top of delivery tube 2 near the right end.

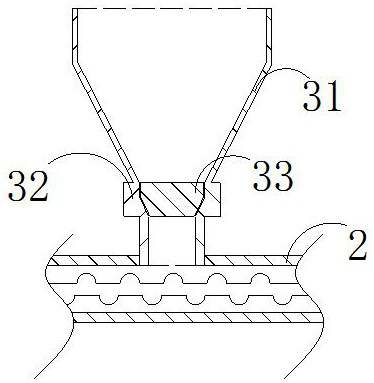

[0031] The funnel 3 includes a funnel body 31 , a connecting block 32 , and a crushing mechanism 33 . The upper surface of the connecting block 32 is fixed on the bottom surface of the funnel body 31 .

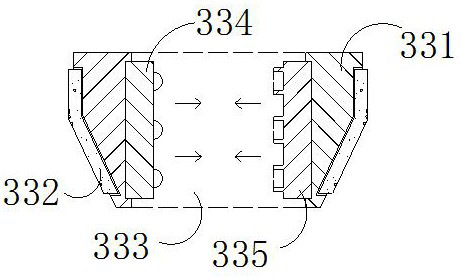

[0032] Wherein, the crushing mechanism 33 includes a support plate 331, a rebound block 332, an opening 333, an impact plate 334, and a matching plate 335. Vertically passing through the upper and lower surfaces of the middle part of the support plate 331, the left side of the impact plate 334 is nested in the left inner wall of t...

Embodiment 2

[0039] as attached Figure 7 to attach Figure 9 Shown:

[0040] Wherein, the feeding pipe 2 includes a pipe body 21, a drainage pipe 22, a screw rod 23, and a diversion mechanism 24, the bottom of the drainage pipe 22 is vertically fixed on the top of the pipe body 21, and the screw rod 23 is arranged inside the pipe body 21, so The surface on both sides of the diversion mechanism 24 is connected with the inner wall of the drainage tube 22 near the bottom end, and the drainage tube 22 is connected with the connection block 32, and the material inside the funnel body 31 is drained to the inside of the tube body 21 through the drainage tube 22, so that The flow diversion mechanism 24 is located near the bottom of the drainage tube 22, and can divide the material and diffuse through the bottom of the drainage tube 22, further increasing the dispersion area of the material.

[0041] Wherein, the diverter mechanism 24 includes a support block 241, a diverter plate 242, a diver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com