A kind of copper-silicon catalyst and its preparation method and application

A catalyst, copper-silicon technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of improving stability, high catalytic performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

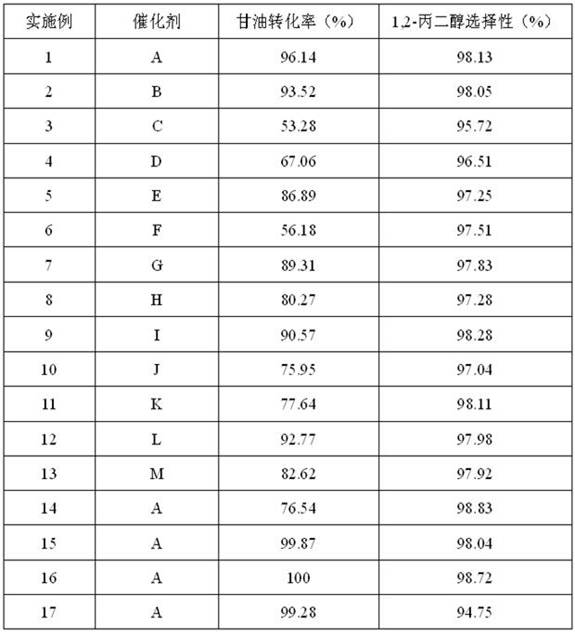

Examples

preparation example Construction

[0025] The preparation method of this copper silicon catalyst:

[0026] Firstly, the amount of copper salt, additive metal salt, magnesium salt, and silica sol was converted according to the amount of catalyst components, and then deionized water was added to the copper salt, additive metal salt, and magnesium salt to obtain a 150 g / L salt solution; Under vigorous stirring, a precipitant solution with a concentration of 100 g / L was added dropwise to the salt solution until the pH value of the salt solution was greater than 11 to obtain a mixed solution; secondly, silicon with a mass concentration of 10-30% was added dropwise to the mixed solution. After the sol was added dropwise, it was aged at 50-80 °C for 4-24 h and then filtered to obtain a precipitate; finally, the precipitate was washed, dried at 110 °C for 12 h, and then roasted and reduced.

[0027] Wherein: copper salt refers to one or more of copper nitrates, sulfates, acetates and halides.

[0028] Auxiliary metal ...

Embodiment 1

[0033] Example 1 A copper-silicon catalyst, in parts by mass, the content of the active metal Cu in the catalyst is 60%, and the auxiliary agent CeO 2 The content is 4%, the carrier magnesium oxide content is 11%, and the balance is carrier SiO 2 .

[0034] Its preparation method: weigh 57.07g Cu(NO 3 ) 2 ·3H 2 O, 17.50g Mg(NO 3 ) 2 ·6H 2 O and 2.52g Ce(NO 3 ) 3 ·6H 2 O Add 510 mL of deionized water to obtain a 150 g / L salt solution; under vigorous stirring, add 100 g / L sodium hydroxide solution dropwise to the salt solution until the pH of the salt solution is greater than 11 to obtain a mixed solution ; 20.83 g of 30 wt% silica sol was added dropwise to the mixed solution. After the dropwise addition, it was aged at 70 °C for 4 h and filtered to obtain a precipitate; the precipitate was washed, dried at 110 °C for 12 h, and dried baked at 500 °C for 4 h; in 20% H 2 -N 2 In the mixed gas flow, it was reduced at 300°C for 4 h to obtain the reduced catalyst A.

Embodiment 2

[0035] Example 2 A copper-silicon catalyst, in parts by mass, the content of the active metal Cu in the catalyst is 30%, and the additive In 2 o 3 The content is 1%, the content of carrier magnesium oxide is 30%, and the balance is carrier SiO 2 .

[0036] Its preparation method: weigh 28.54 g Cu(NO 3 ) 2 ·3H 2 O, 47.72 g Mg(NO 3 ) 2 ·6H 2 O and 0.33 g In(NO 3 ) 3 4H 2 O Add 510 mL of deionized water to obtain a 150 g / L salt solution; under vigorous stirring, add 100 g / L sodium hydroxide solution dropwise to the salt solution until the pH of the salt solution is greater than 11 to obtain a mixed solution ; 32.50 g of 30 wt% silica sol was added dropwise to the mixed solution. After the dropwise addition, it was aged at 70 °C for 4 h and filtered to obtain a precipitate; the precipitate was washed, dried at 110 °C for 12 h, and dried baked at 500 °C for 4 h; in 20% H 2 -N 2 In the mixed gas flow, it was reduced at 300°C for 4 h to obtain the reduced catalyst B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com