Preparation method and application of metal ion modified MOF micro/nano structure in hydrogel

A metal ion modification and hydrogel technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, light water/sewage treatment, etc., can solve the problems of imperfect crystal form and large aggregate size, and improve the reliability Effects of recyclability and high-efficiency photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The porphyrin used in this example is TCPP, provided by Beijing Bailingwei Technology Co., Ltd., without further treatment before use, and its structural formula is shown in formula 1:

[0031]

[0032] Concrete preparation steps are as follows:

[0033] 1) 0-20mg ZrCl 4 and 0-20 mg of TCPP were dissolved in 1-10 mL of DMF solution, and then 50-200 μL of acetic acid and 10-100 μL of deionized water were added.

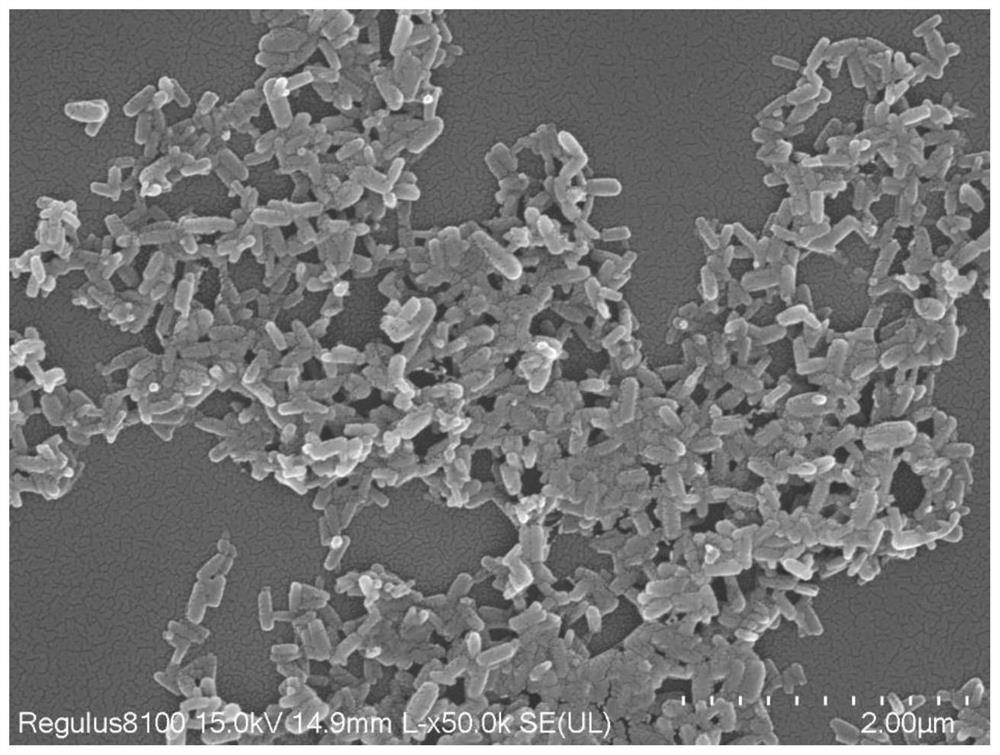

[0034] 2) The mixed solution is magnetically stirred at room temperature for 5-30 minutes, then the solution is sealed and heated at 100-200°C. After reacting for 5-15 hours, centrifuge, dry and collect samples. figure 1 It can be seen that the size of porphyrin MOF is 100-800nm.

[0035] Performance Testing:

[0036] 1) Weigh 1-20mg of porphyrin MOF powder collected by traditional solvothermal reaction and add it to 10-100mL, 0.01-0.1mM MB solution. 100mW / cm 2 ) under irradiation for 100 minutes, samples were taken every 10 minutes and carried out the ...

Embodiment 2

[0038] 1) Configure Zn with excessive concentration 2+Salt solution 10-100ml, weigh 10-100mg of SA powder and add 1-10ml of deionized water. Weigh 1-10 mg of the porphyrin MOF powder obtained in Example 1, add 1-10 ml of water to prepare a MOF dispersion.

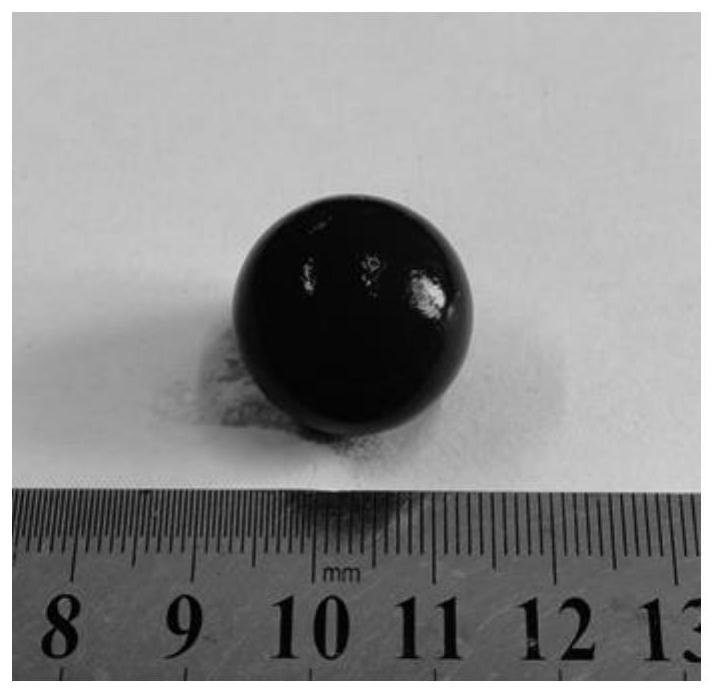

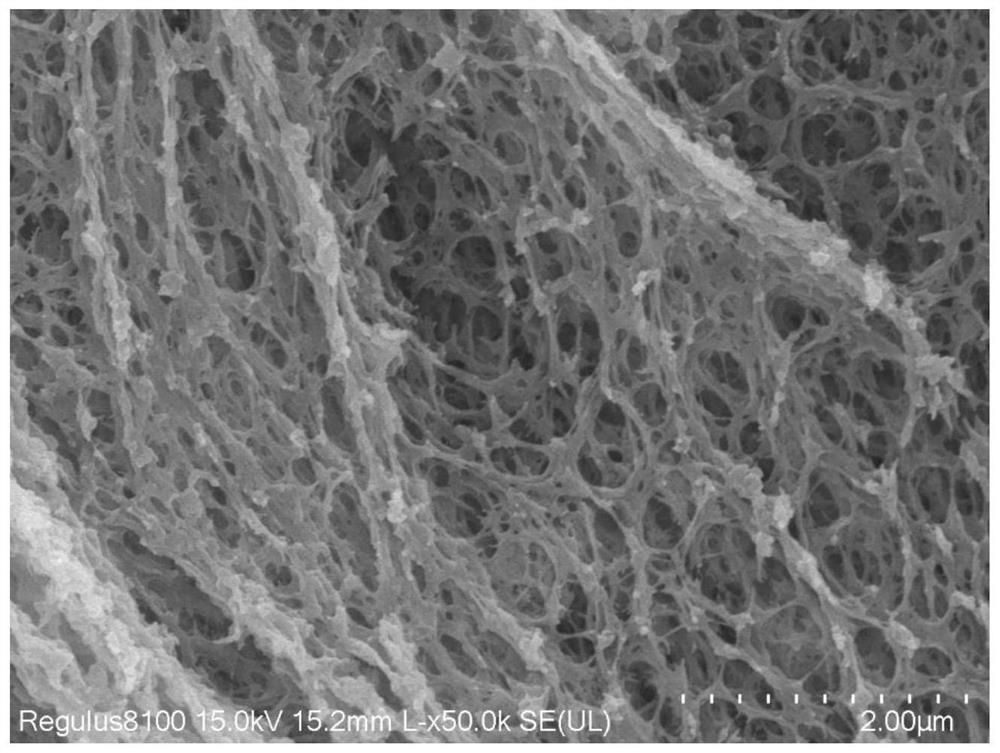

[0039] 2) Mix the SA aqueous solution in 1) and the porphyrin MOF dispersion, stir for 5-30 minutes, freeze and set, add the Zn in 1) 2+ saline solution, the resulting SA-M 2+ -MOF hydrogel spheres see figure 2 with image 3 .

[0040] Performance Testing:

[0041] 1) SA-M obtained by metal ion modification method 2+ -MOF hydrogel balls were added to 10-100mL, 0.01-0.1mM MB solution, and after the adsorption-desorption equilibrium was carried out under dark conditions, in simulated sunlight (illumination intensity 100mW / cm 2 ) under irradiation for 100 minutes, samples were taken every 10 minutes and carried out the UV-visible absorption spectrum test; for the sample test performance results prepared in embodiment 1...

Embodiment 3

[0043] Repeat embodiment 2, its difference is only that the metal ion in step 1) is Co 2+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com