Adjustable tuyere structure

An adjustable, air-nozzle technology, applied in the pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of low heat utilization rate, slow drying speed, and formation of tension lines on the surface of the material film, etc. Achieve the effect of improving heat exchange efficiency, reducing equipment costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

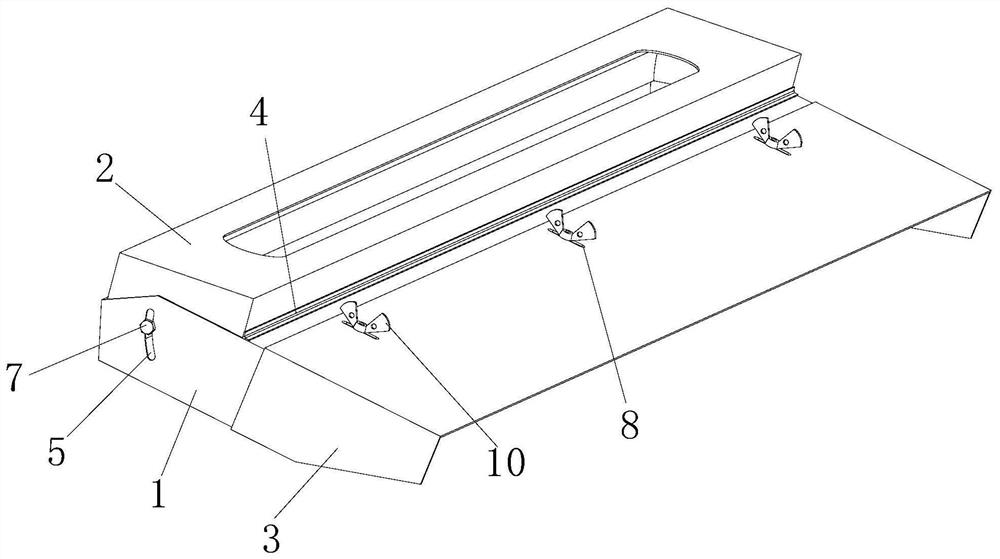

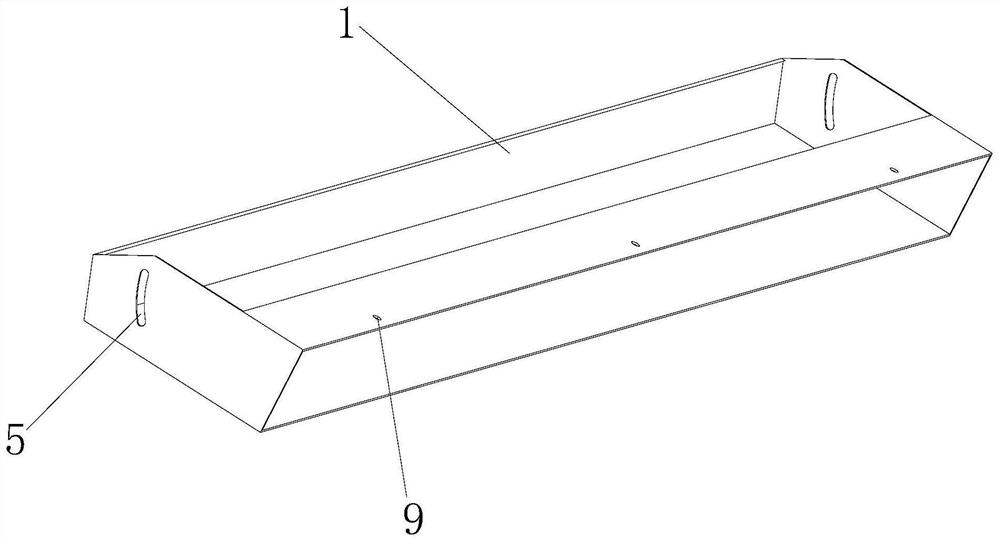

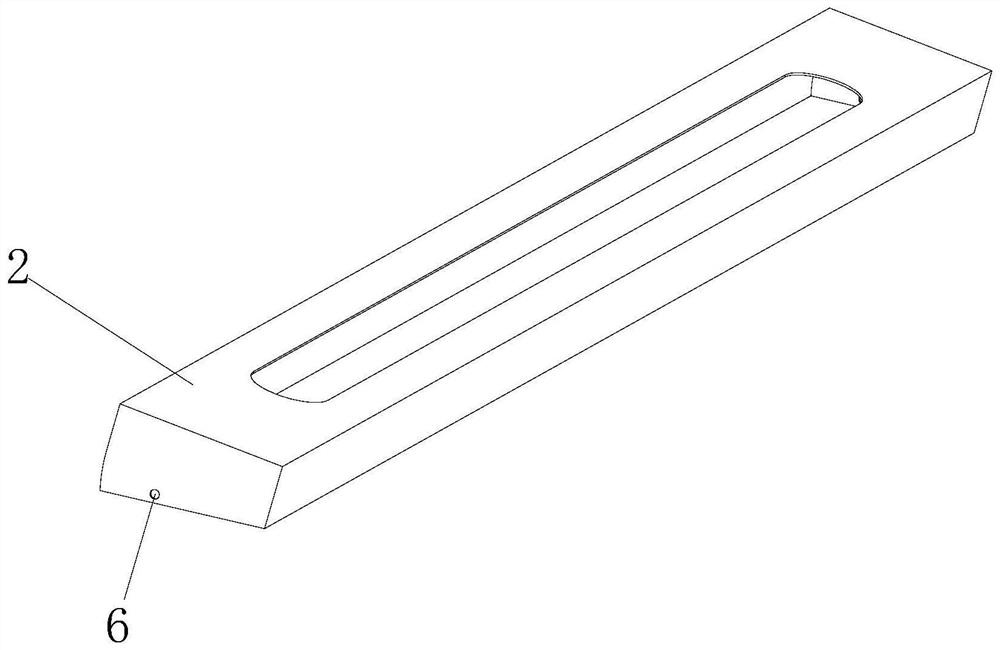

[0020] The invention provides an adjustable tuyere structure, such as Figure 1 to Figure 5 As shown, the air nozzle body 1 is included, the material film 13 and the guide roller 14 supporting the material film 13 are located below the air nozzle body 1, the air inlet of the air nozzle body 1 is opened upwards and the air box 2 with the bottom opening is movably sleeved, The top of the wind box 2 is provided with an opening and is connected with a wind bladder 11, the wind bladder 11 is connected with the wind box 2 through a buckle 12, and the joint is sealed with high temperature resistant silicon rubber. An angle adjustment mechanism is connected between the air box 2 and the nozzle body 1 , a nozzle cover 3 is movably sleeved in front of the air outlet of the nozzle body 1 , and a length adjustment mechanism is arranged between the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com