A selective wave soldering pin header structure

A wave soldering and selective technology, applied in the direction of welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of inconvenient adjustment, inconvenient flue gas purification, inconvenient adjustment of solder bucket, etc., achieve good positioning effect and increase stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

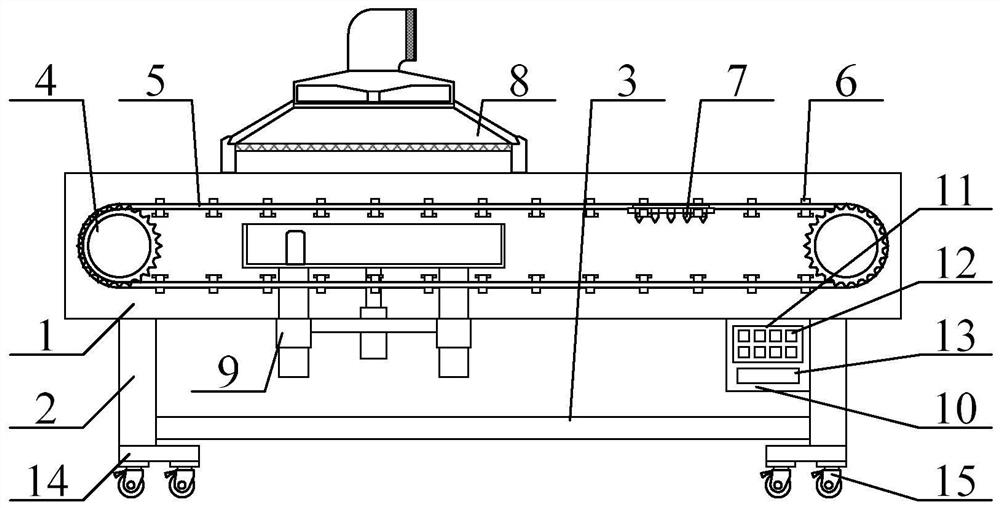

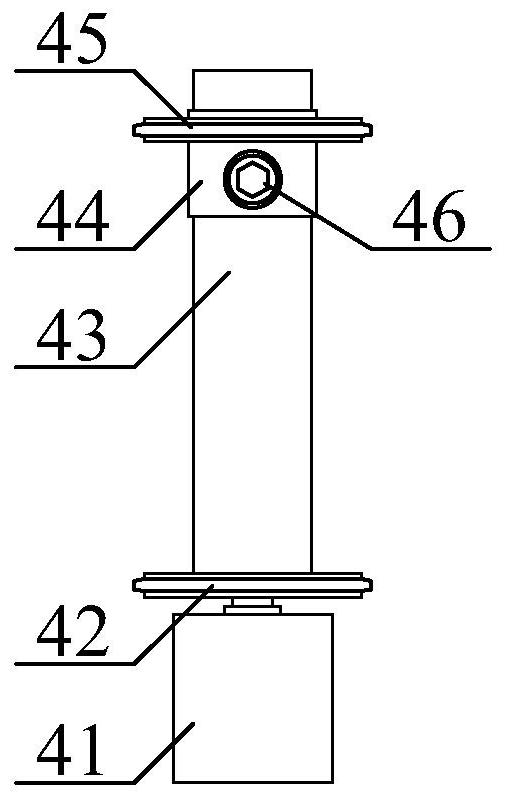

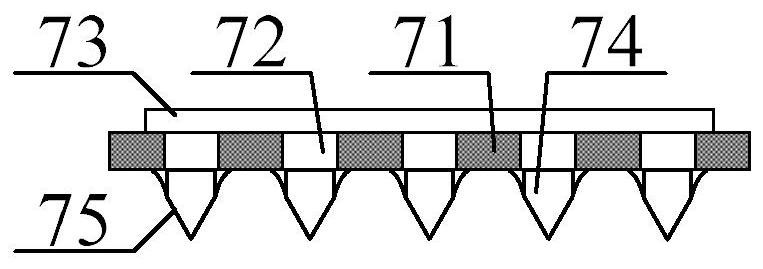

[0037] as attached figure 1 And attached figure 2As shown, the present invention provides a selective wave soldering pin arrangement, which includes a conveying outer frame 1, a longitudinal support 2, a bottom fixing frame 3, an adjustable drive frame structure 4, a conveying chain 5, an L-shaped backing plate 6, and a pin arrangement Frame structure 7, smoke emission and purification frame structure 8, adjustable lifting frame structure 9, control console 10, control panel 11, control button 12, controller 13, fixed bottom plate 14 and brake wheel 15, and the longitudinal support 2 is welded At the lower four corners of the conveying frame 1; the bottom fixing frame 3 bolts are installed on the inner lower part of the longitudinal support 2; the adjustable driving frame structure 4 is installed on the left and right sides of the conveying frame 1; The L-shaped backing plate 6 screws are installed on the inner side of the conveyor chain 5; the needle rack structure 7 is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com