Laser welding jig

A laser welding and jig technology, which is applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of potential safety hazards, uneven glass lamination, and difficult uniform clamping force of jigs, etc., so as to facilitate welding Uniform operation, clamping force, uniform fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing:

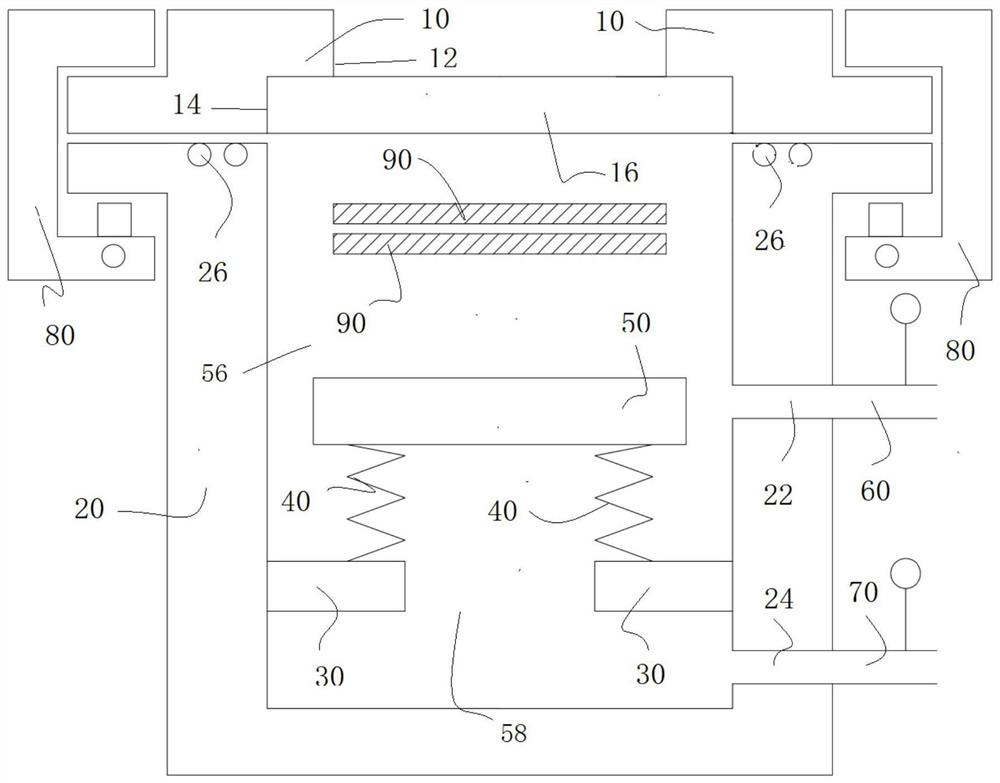

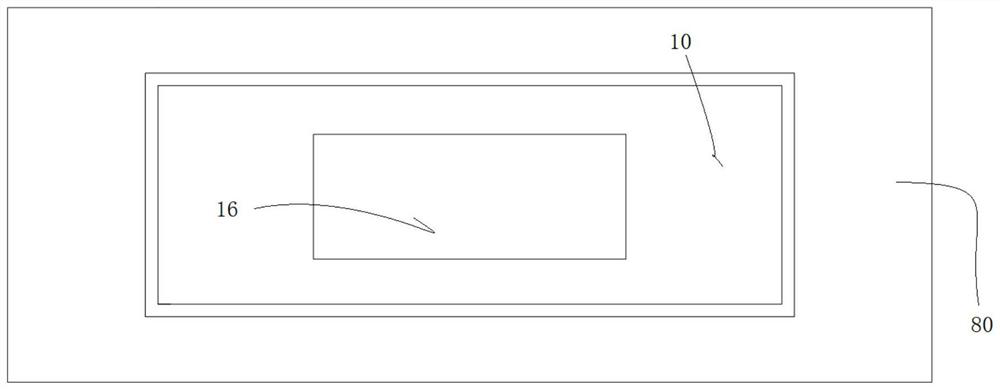

[0043] According to an embodiment of the present invention, a laser welding jig is provided. see figure 1 and figure 2 , the laser welding jig includes a lower casing 20 , an upper cover 10 , a support member 30 , an elastic member 40 and a bearing member 50 . Wherein, the upper cover 10 is provided with a transparent window 16 . The upper cover 10 is detachably connected to the lower case 20 . The upper cover 10 can be connected with the lower casing 20, or can be disassembled and separated.

[0044] The supporting member 30 is fixedly connected to the inner wall of the sealed cavity, and is used for supporting the connecting elastic member 40 . One end of the elastic member 40 is connected to the supporting member 30 . The bearing member 50 is connected to the other end of the elastic member 40 and can be used to place the workpiece 90 to be welded. The elastic membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com