Chain winding ratchet wheel maintenance method

A ratchet and threaded hole technology, which is applied in the field of railway wagon braking system transformation, can solve problems such as excessive cost, unremovable screw, and maintenance, so as to ensure product quality and performance safety, improve maintenance passability, and meet maintenance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

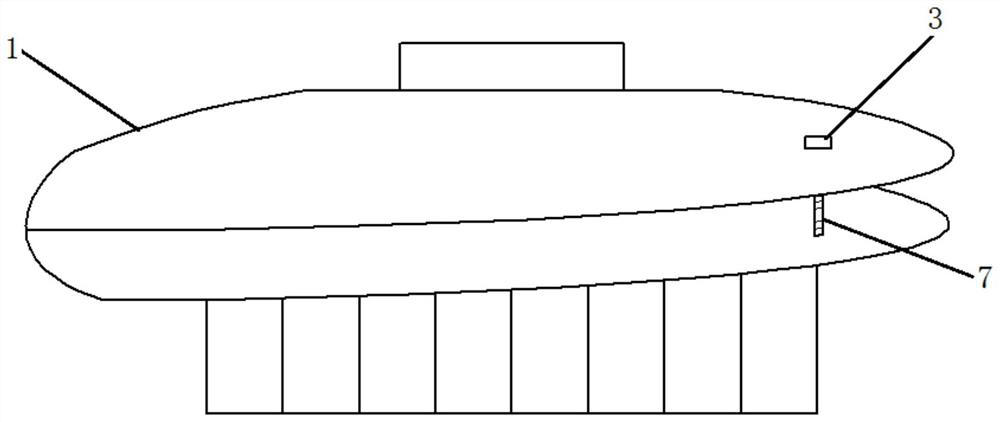

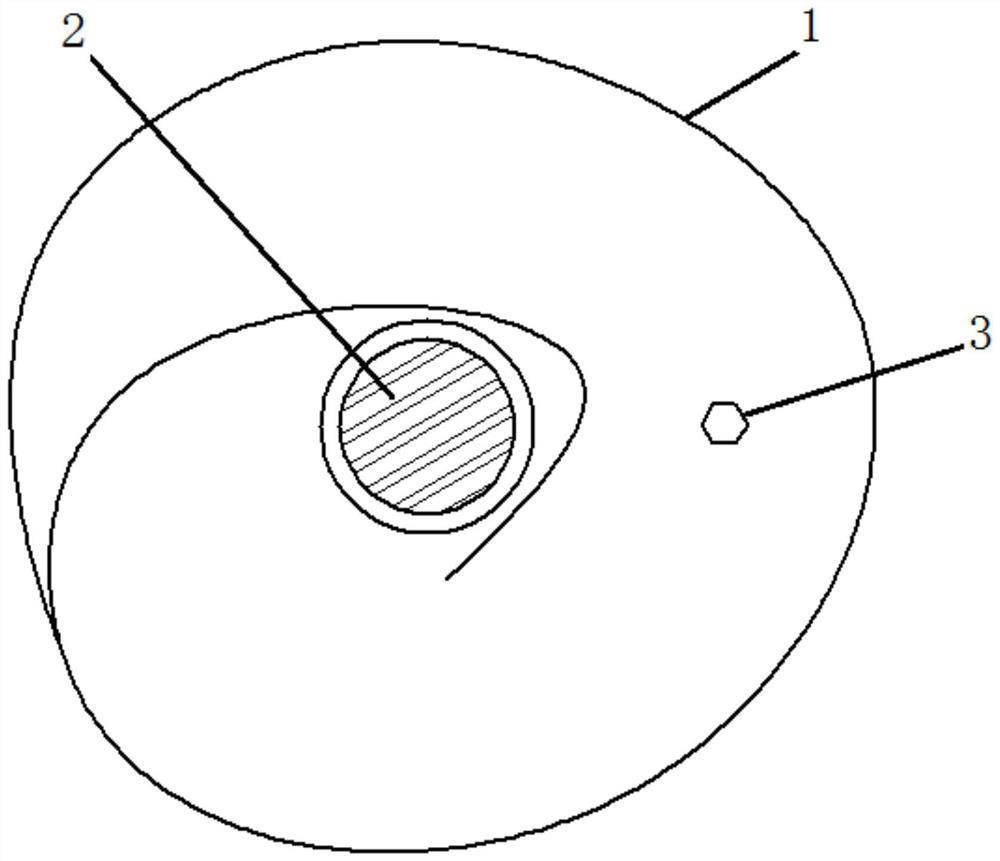

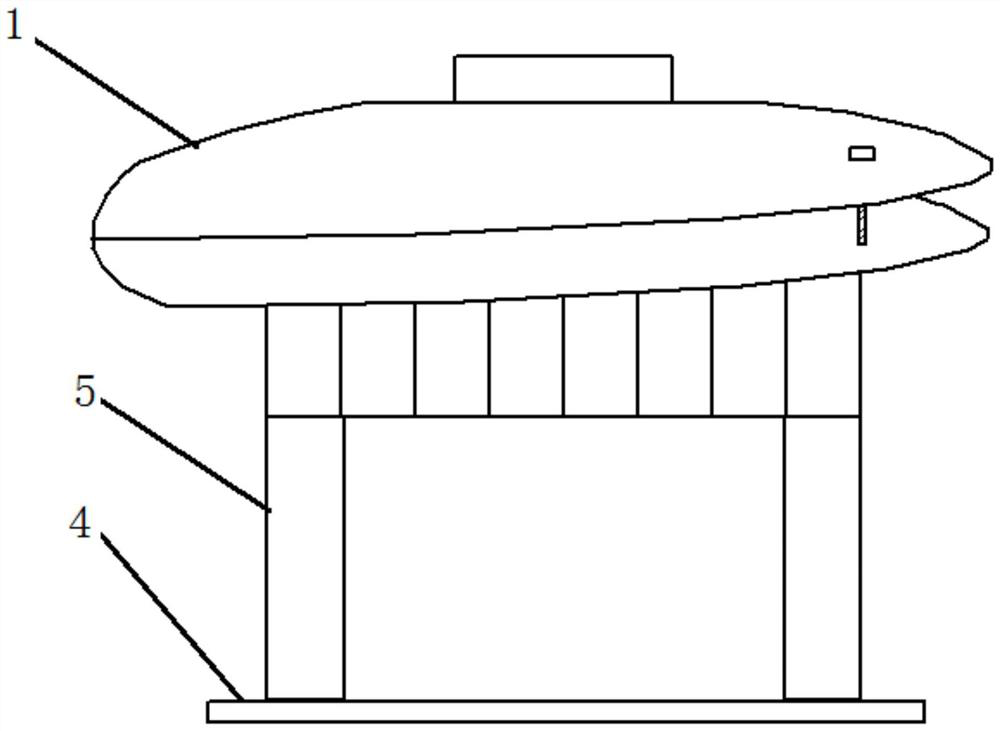

[0081] Such as Figure 1 to Figure 5 As shown, the present invention provides a method for overhauling a chain-wound ratchet, comprising:

[0082] Take out the rusted or welded shaft 2 in the shaft hole of the winding ratchet 1;

[0083] Take out the rusted or welded bolt 3 in the threaded hole of the chain ratchet 1;

[0084] Counterbore processing and hole reaming processing are carried out sequentially to the first threaded hole of the chain-wound ratchet 1 .

[0085] In this embodiment, taking out the rusted or welded shaft 2 in the shaft hole of the winding ratchet 1 includes:

[0086] Carrying out high-temperature treatment to the shaft rod 2;

[0087] Remove the welding slag at the end of the shaft 2;

[0088] Place the chain-wound ratchet 2 on the first tooling 4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com