Clamping device for automatic helmet drilling machine

A technology of clamping device and drilling machine, which is applied in the direction of clamping device, positioning device, clamping, etc., can solve the problems of clamp clamping difficulty, helmet processing position deviation, and many scrapped products, so as to ensure the convenience of use, The effect of guaranteeing precision and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be clearly and completely described below in conjunction with the embodiments.

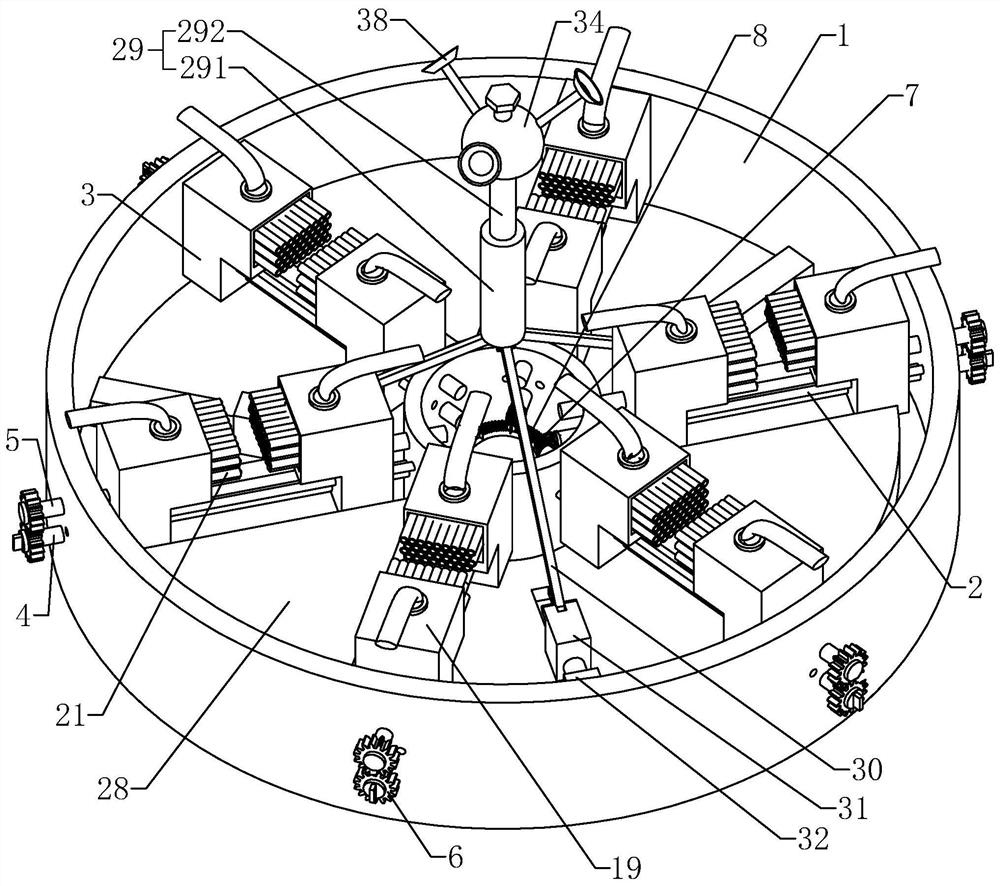

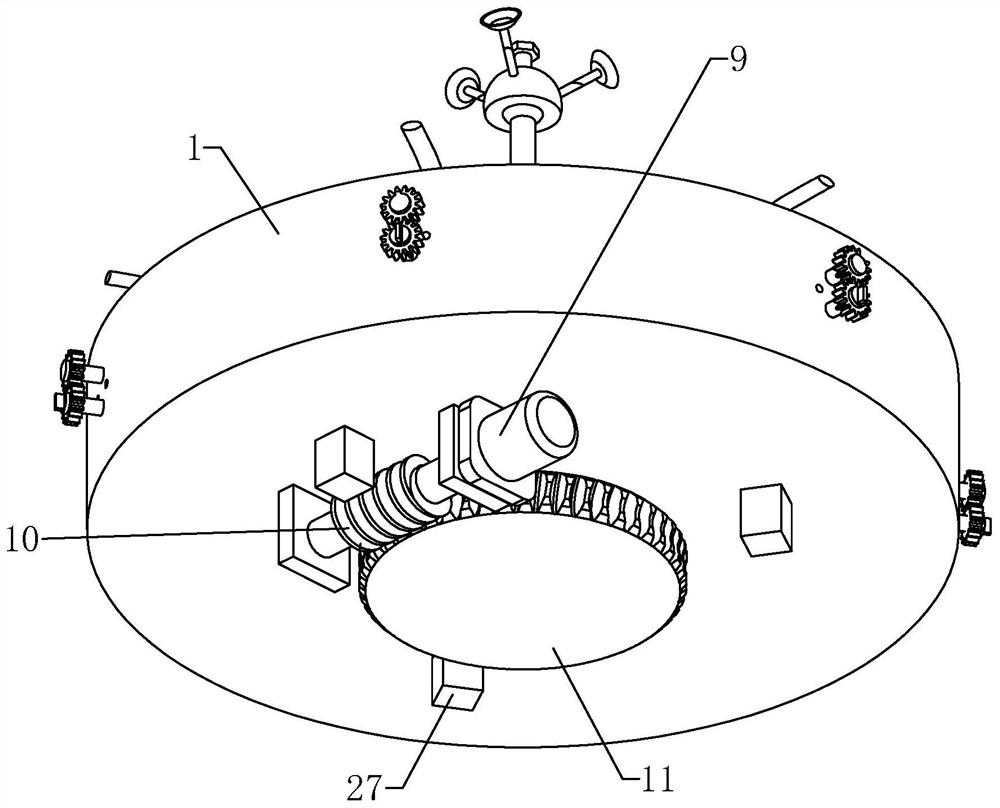

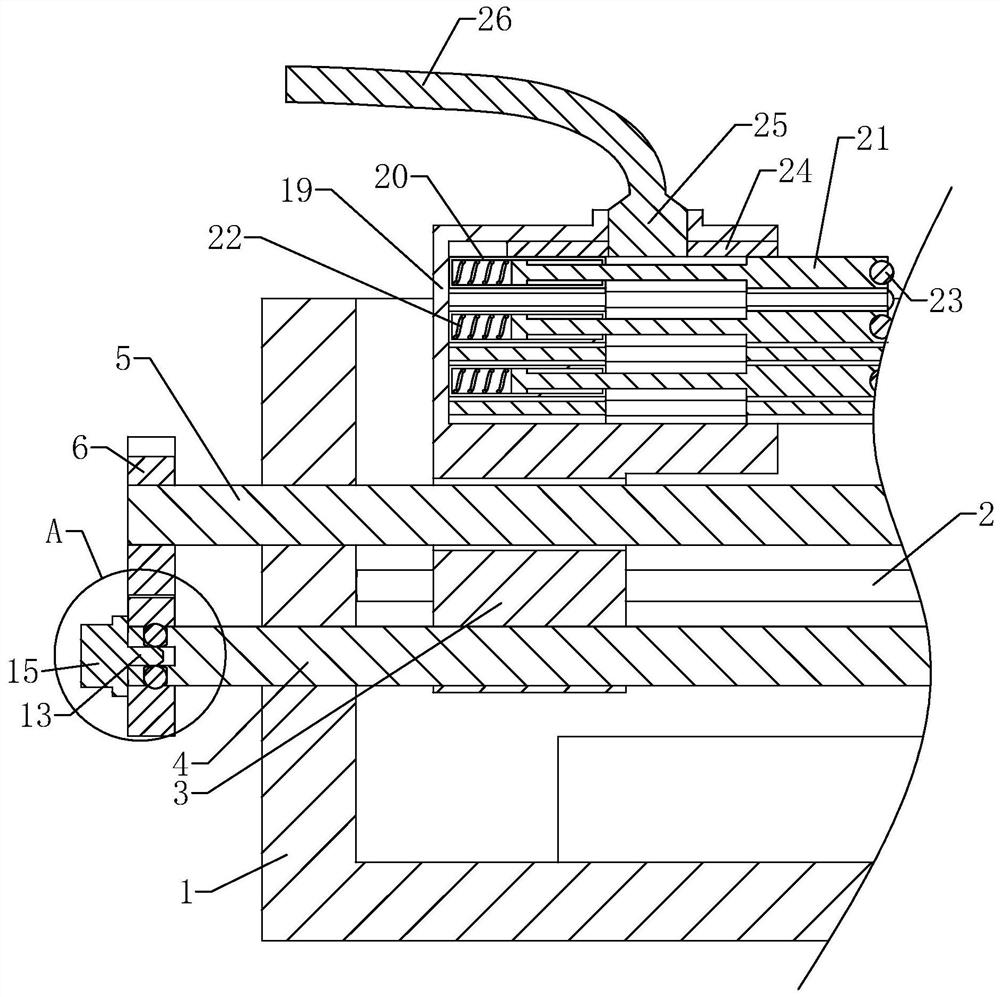

[0032] See attached figure 1 , a clamping device for an automatic helmet drilling machine, including a workbench 1, the workbench 1 is a disc-shaped structure, and the workbench 1 is installed on the helmet automatic drilling machine when practical. There are six radial clamping mechanisms on the workbench 1. The clamping mechanism includes two cylindrical rod-shaped slide rails 2 fixed on the workbench 1. Two slide seats 3 are provided for sliding on the slide rails 2. The clamping mechanism also includes a first threaded rod 4 and a second threaded rod 5 that are rotatably engaged with the workbench 1. The first threaded rod 4 and the second threaded rod 5 are threadedly engaged with the two sliding seats 3 respectively. The ends of the rod 4 and the second threaded rod 5 away from the axis of the workbench 1 are both provided with transmission gears 6 that mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com