High-precision temperature control film casting machine

A film casting, high-precision technology, applied in the field of casting machines, can solve problems such as the inability of the melt to move uniformly and at a constant speed, affecting the lateral thickness of the plastic film, and unreasonable fluctuations in the film-forming temperature, achieving compact structure and easy installation. , the effect of fast cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

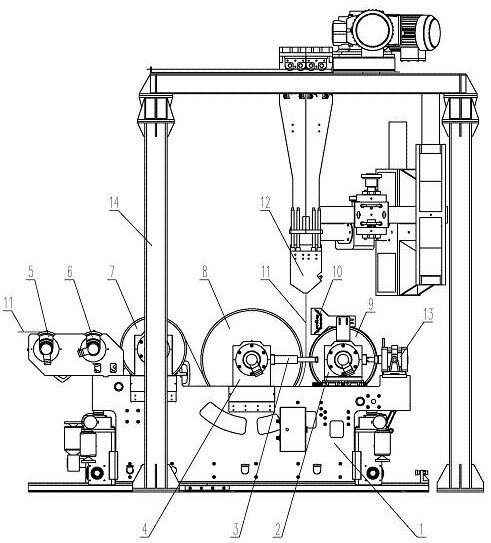

[0027] Such as figure 1 The high-precision temperature-controlled film casting machine shown, the casting machine includes a frame 1, on the frame structure 1 through symmetrically arranged bearing seats, the rubber roller 9, the patterned roller 8, Grinding roller 7, cooling roller 1 6 and cooling roller 2 5, the rotating supporting seat of opposite-rolling rubber roller 9 and pattern roller 8 can be displaceably supported on the frame 1, on the pattern roller support 4 of pattern roller 8 A pattern roller adjusting screw 3 for adjusting the position of the pattern roller 8 is provided, the pattern roller support 4 is movably supported on the frame 1 , and the pattern roller adjusting screw 3 is also supported on the frame 1 . On the rubber roller support 2 of the rubber roller 9, a pressure cylinder 13 is supported in a conflicting manner. The rubber roller support 2 is movably supported on the frame 1, and the pressure cylinder 13 is hinged on the machine through its pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com