Packaging structure of MEMS pressure sensor

A pressure sensor and packaging structure technology, applied in microstructure technology, microstructure devices, measuring fluid pressure, etc., can solve problems such as signal interference, achieve the effects of improving reliability, improving processing quality and efficiency, and reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

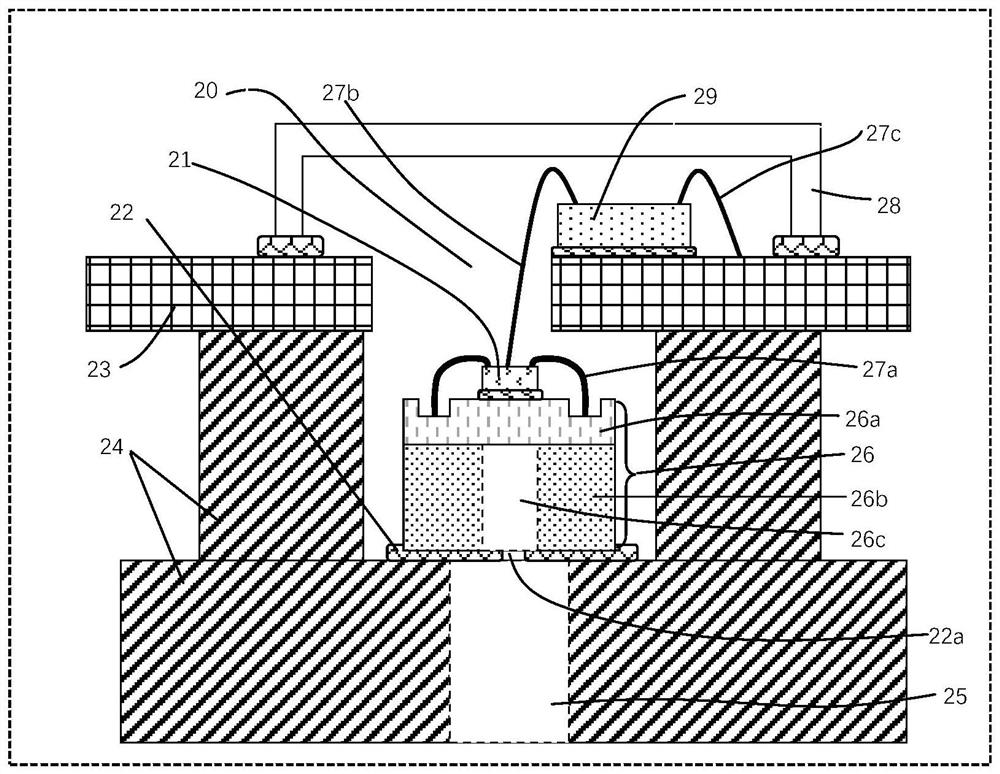

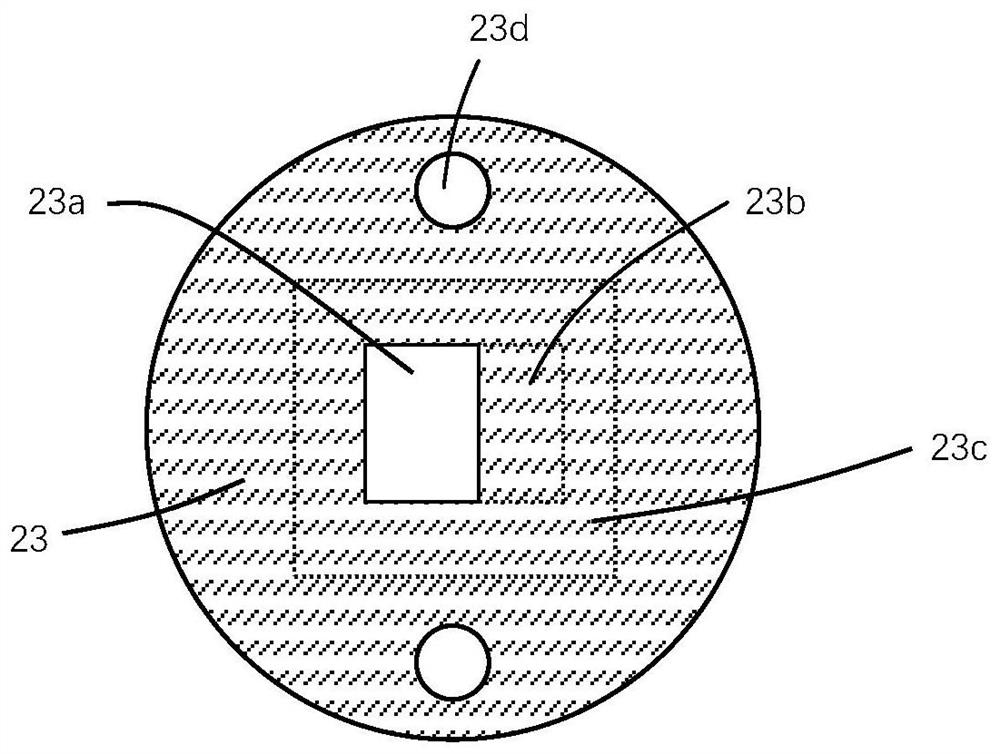

[0028] A package structure of a MEMS pressure sensor, such as figure 2 As shown, it includes a metal base 24, a MEMS pressure sensor chip 26, a PCB board 23, an adapter plate 21, an ASIC chip 29 and a cover plate 28, and the metal base 24 (commonly stainless steel, according to the needs of the application scene, such as water-resistant steam, salt spray resistance, etc., can be different grades of stainless steel, such as 304, 420, etc.) There is a cavity 20 inside, and the cavity 20 is used to install the MEMS pressure sensor chip 26. There is a vent hole 25 on the metal base 24. One end of the air hole 25 communicates with the outside world, and the other end communicates with the cavity 20 for receiving external environmental pressure (air pressure or hydraulic pressure). According to application requirements, the air hole 25 can be made into different interfaces, such as G1 / 4 internal (external) thread, etc. .

[0029] The MEMS pressure sensor chip 26 uses silicon proce...

Embodiment 2

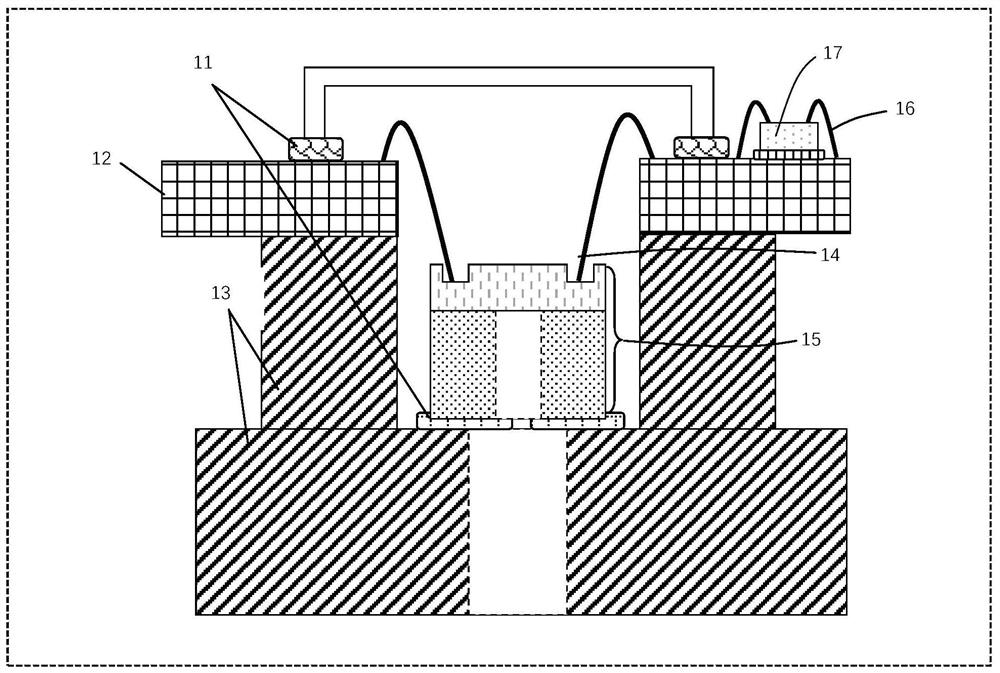

[0035] The packaging structure of the MEMS pressure sensor of the present embodiment is as follows Figure 5 As shown, compared with the embodiment, this embodiment only removes part of the PCB board 23e extending from the metal base 24 to the adapter plate 21, and the first metal lead 27a is connected to the adapter plate from the MEMS pressure sensor chip 26 21. The second metal lead 27b is connected to the ASIC chip 29 from the adapter board 21, and the third metal lead 27c is led out from the ASIC chip 29 to the PCB board 23, and connected to the subsequent circuit.

Embodiment 3

[0037] Compared with the second embodiment, this embodiment reduces the height 24a of the metal base 24 to achieve the purpose of further reducing the wire bonding height, as Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com