Synthesis method of calcium hydroxide with high specific surface area

A high specific surface area, calcium hydroxide technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of sample agglomeration, low product purity, limited application, etc., and achieve the effect of preventing particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

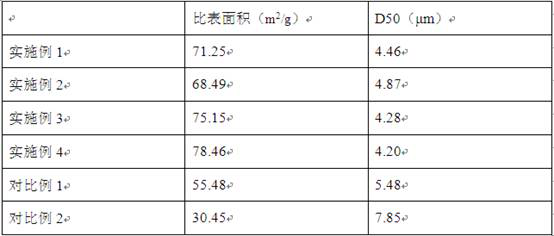

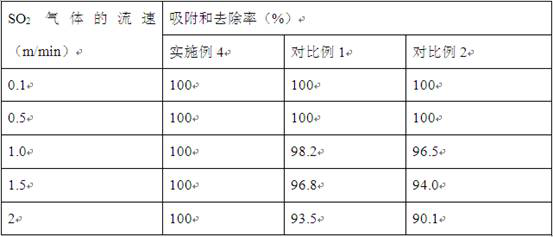

Examples

Embodiment 1

[0037] A kind of synthetic method of high specific surface area calcium hydroxide, comprises the following steps:

[0038] Add 100kg of pure water and 100kg of heavy calcium into the reaction kettle, start stirring, raise the temperature to 40°C, add hydrochloric acid dropwise to it until the pH reaches 2, and keep stirring for 2 hours to obtain the reaction solution, filter and separate, and discard the filter cake to obtain CaCl 2 solution;

[0039] 10kg of cetyltrimethylammonium bromide and 60kg of liquid caustic soda are placed in the reaction device, the stirring is started, and the temperature is raised to 60°C, and the step The resulting CaCl 2 The solution was dripped into the reaction device, after the dripping was completed, the temperature was kept for 0.5 hours, suction filtered and rinsed to obtain a filter cake;

[0040] The mass concentration of liquid caustic soda is 28%;

[0041] Take 4kg of mono-6-amino-6-deoxy-β-cyclodextrin and 1kg of aminated gra...

Embodiment 2

[0044] A kind of synthetic method of high specific surface area calcium hydroxide, comprises the following steps:

[0045] Add 300kg of pure water and 100kg of heavy calcium into the reaction kettle, start stirring, raise the temperature to 80°C, add hydrochloric acid dropwise to it until the pH reaches 4, keep stirring for 1 hour to obtain the reaction solution, filter and separate, discard the filter cake, and obtain CaCl 2 solution;

[0046] 30kg of cetyltrimethylammonium bromide and 80kg of liquid caustic soda are placed in the reaction device, the stirring is started, the temperature is raised to 80°C, and the step The resulting CaCl 2 The solution is dripped into the reaction device, after the dripping is completed, the temperature is kept for 1 hour, and the filter cake is obtained by suction filtration and rinsing;

[0047] The mass concentration of liquid caustic soda is 32%;

[0048] Take 6kg of mono-6-amino-6-deoxy-β-cyclodextrin and 3kg of aminated graphe...

Embodiment 3

[0051] A kind of synthetic method of high specific surface area calcium hydroxide, comprises the following steps:

[0052] Add 220kg of pure water and 100kg of heavy calcium into the reaction kettle, start stirring, raise the temperature to 50°C, add hydrochloric acid dropwise to it until the pH reaches 2.5, keep stirring for 1.5 hours to obtain the reaction solution, filter and separate, and discard the filter cake to obtain CaCl 2 solution;

[0053] 15kg of cetyltrimethylammonium bromide and 65kg of liquid caustic soda are placed in the reaction device, the stirring is started, the temperature is raised to 65°C, and the step The resulting CaCl 2 The solution is dripped into the reaction device, after the dripping is completed, it is kept warm for 40 minutes, filtered with suction and rinsed to obtain a filter cake;

[0054] The mass concentration of liquid caustic soda is 31%;

[0055] Take 4.5kg of mono-6-amino-6-deoxy-β-cyclodextrin and 2.5kg of aminated graphene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com