Combined drilling and grouting pipe for grouting reinforcement of soft stratum of island reef and construction method

A grouting reinforcement technology for weak strata, which is applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., and can solve problems such as insufficient grout pressure at the end of the grouting pipe, inability of grout to enter smoothly, and inability to reach the reinforcement depth, etc. , to achieve the effect of ensuring long-term stability, good effect of grouting and water blocking, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

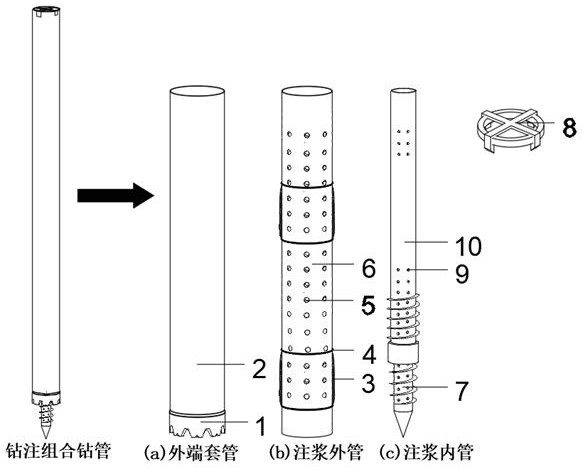

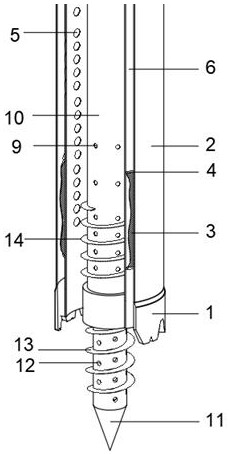

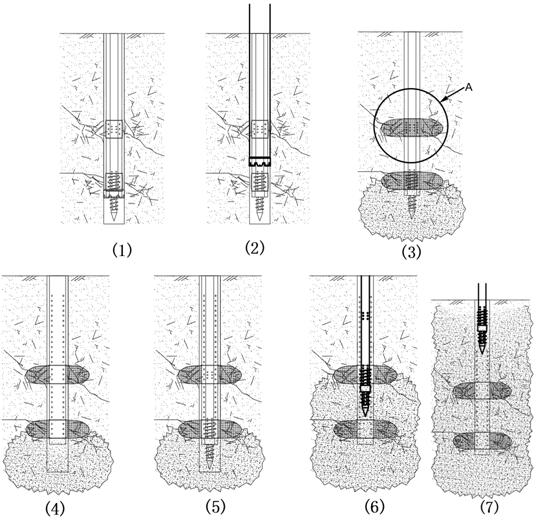

[0059] see image 3 In steps (1)-(7), the present invention also provides a combined drilling and injection pipe and a construction method for grouting reinforcement of weak formations on islands and reefs.

[0060] Preliminary preparations: Transport the combined drilling and injection pipe to the construction site, check all parts, and partially seal the outer grouting pipe with a slightly smaller-diameter plastic sleeve so that only the membrane bag binding section of the outer grouting pipe is opened Flower hole, then combine the outer casing, the grouting inner pipe and the grouting outer pipe, and fix it with a sealing steel buckle;

[0061] Step (1): Drilling. Use rotary drilling and injection equipment to drill the combined drilling and injection pipe to the expected depth, and pressurize the combined drilling and injection pipe to the predetermined depth while rotating. Drilling and crushing of formation rock and soil;

[0062] Step (2): Recover the outer casing. ...

Embodiment 2

[0069] see image 3 In steps (1)-(7), the present invention also provides a combined drilling and injection pipe and a construction method for grouting reinforcement of weak formations on islands and reefs.

[0070] The preparatory work and steps (1)-(5) of Example 2 are the same as those in Example 1.

[0071] Steps (6)-(7): Pump cement-based single-liquid slurry into the grouting inner pipe, inject water glass slurry into the annular cavity between the grouting outer pipe and the grouting inner pipe, cement-based single-liquid slurry and water glass slurry The volume ratio is preferably 1:1-3:1. The inner grouting pipe is slowly lifted from the depths of the foundation while injecting reverse high-pressure injection until the inner pipe is completely removed. In this process, the weak stratum of the island and reef is reinforced by grouting twice.

[0072] Such as Figure 5 As shown, the grout diffusion radius R in steps (6)-(7) can exceed 6 m at most, and the grouted inn...

Embodiment 3

[0074] see image 3 In steps (1)-(7), the present invention also provides a combined drilling and injection pipe and a construction method for grouting reinforcement of weak formations on islands and reefs.

[0075] The preparatory work and steps (1)-(5) of Example 3 are the same as those in Example 1.

[0076] Steps (6)-(7): pump cement-water glass double liquid slurry into the grouting inner pipe, the volume ratio of cement slurry to water glass slurry is preferably 1:1-3:1. The grouting inner pipe is lifted from the depths of the foundation while reversely rotating the grouting until the inner grouting pipe is completely taken out. In this process, the weak formation of the island and reef is reinforced by the second full-scale grouting.

[0077] Such as Figure 5 As shown, the grout diffusion radius R in steps (6)-(7) is about 3-6 m, and the grouted inner pipe and outer casing can be recycled for multiple effective recycling, and the grouting reinforcement for the next h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com