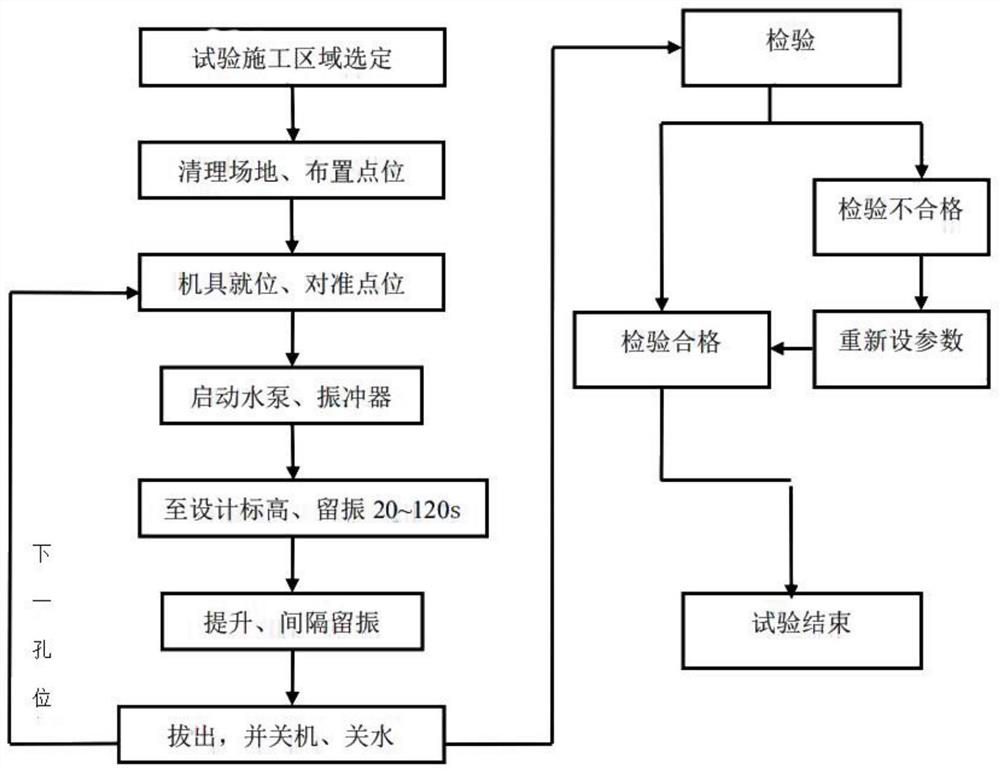

Vibroflotation compaction method for pipeline backfill construction

A compact and pipeline technology, applied in excavation, soil protection, infrastructure engineering, etc., can solve the problems of slow construction speed and low efficiency, and achieve the effect of improving construction efficiency and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: Vibration compaction treatment is performed on the backfill area of the pipeline.

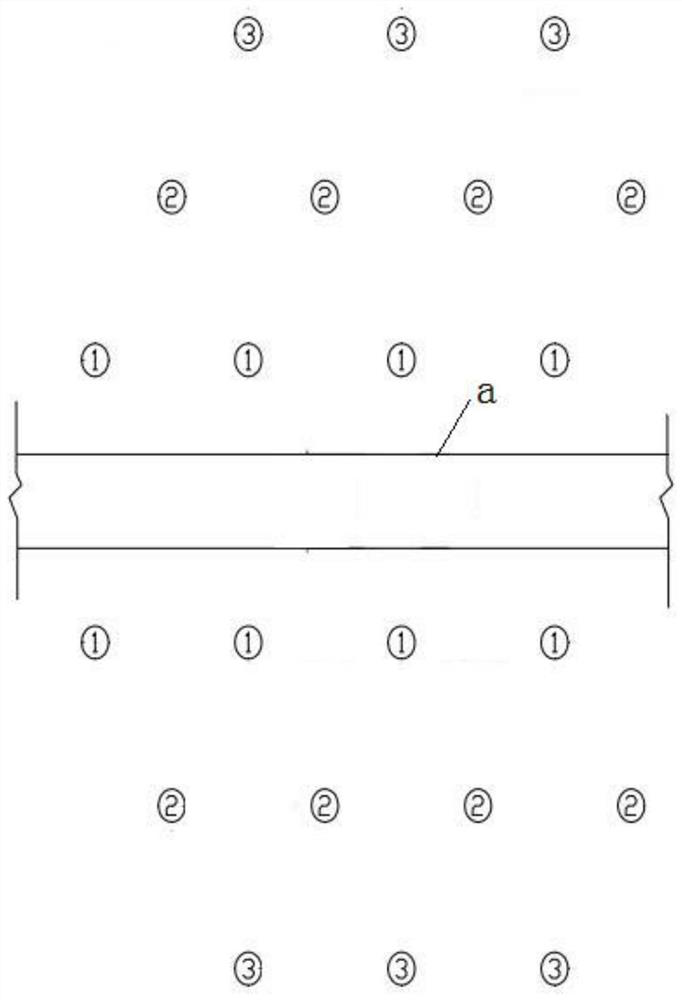

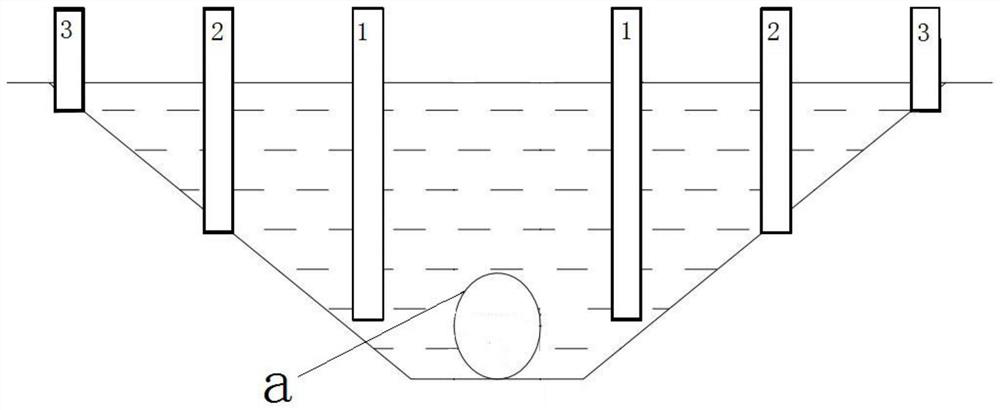

[0031] Instructions attached figure 2 And attached image 3 The reference mark a in the figure is a pipeline, and the diameter of the pipeline is 100cm. The number 1 in the figure represents the first row of holes, the number 2 in the figure represents the second row of holes, and the number 3 in the figure represents the third row of holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com