Device and method for testing strain position of object by using external strain

A testing device and testing method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of no real-time monitoring and calculation methods, and achieve the effect of real-time monitoring and calculation and solving cumulative errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with drawings and embodiments.

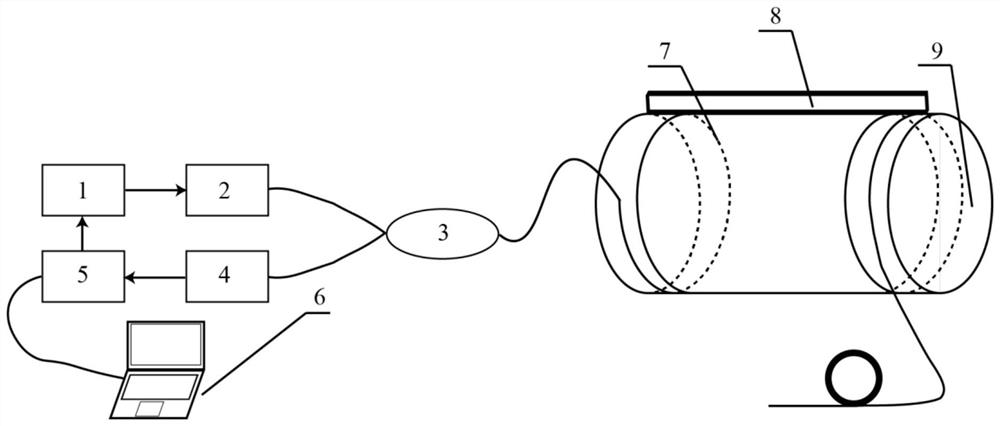

[0064] Such as figure 1 As shown, the device includes a light source driving circuit 1, a light source 2, a 2×2 optical coupler 3, a photodetector 4, a sensing fiber 7 and a strain applying device 8; the light source driving circuit 1 is connected to the light source 2, and the light output of the light source 2 The end is connected to one end on one side of the 2×2 optical coupler 3, the other end on one side of the 2×2 optical coupler 3 is connected to the photodetector 4, and the other end on the other side of the 2×2 optical coupler 3 is connected to the sensing fiber 7, the other end of the other side of the 2×2 optical coupler 3 and the other end of the sensing fiber 7 are used as empty ports to connect to the pigtail. The strain applying device 8 is a strip-shaped object that can be made of any material and is attached to a certain circumferential position in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com