Material thermal and mechanical loading performance testing device

A testing device and technology of learning mechanics, applied in the field of material thermomechanical loading performance testing device, can solve the problems of long heating and cooling time, inaccurate simulation, large test error, etc., and achieve long heating time, small test error and good synchronization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

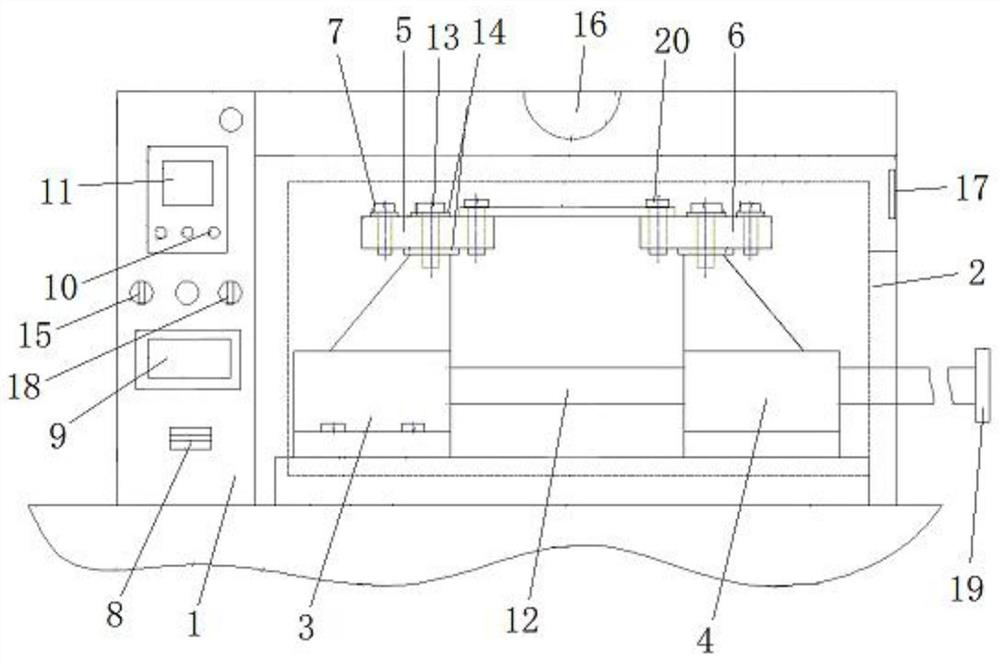

[0020] Such as figure 1 Shown is the structural representation of the present invention:

[0021] The invention provides a material thermomechanical loading performance testing device, comprising a box body 1, on which a sliding door 2, a power switch 8, a temperature strain display 9, a current adjustment knob 10, and a voltage and current display 11 are arranged, The box body 1 is equipped with a fixed support 3, a sliding support 4, a screw rod 12, a strain gauge, and a thermocouple. The fixed support 3 is fixed on the bottom of the box body 1, and the sliding support 4 is connected to the bottom of the box body 1 through a slide rail. , the screw mandrel 12 is rotationally connected with the fixed support 3, the screw mandrel 12 is screwed with the sliding support 4, the fixed support 3 is insulatedly fixed with a first clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com