A Vibration Data Cleaning Method Based on Interval Standard Deviation Combined with Spectrum Analysis

A spectrum analysis and vibration data technology, applied in electrical digital data processing, special data processing applications, testing of machine/structural components, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

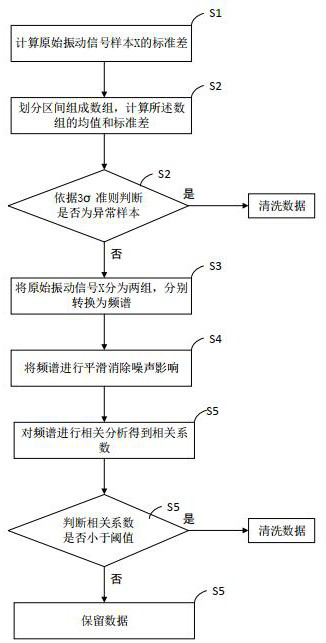

[0105] Such as figure 1 As shown, a vibration data cleaning method based on interval standard deviation combined with spectrum analysis includes the following steps:

[0106] S1. Calculate the standard deviation of the original vibration signal sample X;

[0107] S2. Calculate the periodic data length of the original vibration signal sample X according to the equipment speed, multiplier, and sampling frequency and divide the intervals to form an array, calculate the mean value and standard deviation of the array, and judge whether the original vibration signal sample X is an abnormal sample according to the 3σ rule. If it is judged to be yes, perform cleaning, if it is judged to be otherwise, go to step S3;

[0108] S3. Divide the original vibration signal sample X into two groups, and convert them into frequency spectra respectively;

[0109] S4, smoothing the frequency spectrum to eliminate noise influence;

[0110] S5. Carry out correlation analysis on the frequency spec...

Embodiment 2

[0112] Such as figure 1 As shown, a vibration data cleaning method based on interval standard deviation combined with spectrum analysis includes the following steps:

[0113] S1. Calculate the standard deviation of the original vibration signal sample X;

[0114] Original vibration signal sample X standard deviation for:

[0115] ,

[0116] Among them, the original vibration signal sample X is , L is the number of sampling points of the original vibration signal sample X, is the average value of the original vibration signal sample X;

[0117] ;

[0118] S2. Calculate the periodic data length of the original vibration signal sample X according to the equipment speed, multiplier, and sampling frequency and divide the intervals to form an array, calculate the mean value and standard deviation of the array, and judge whether the original vibration signal sample X is an abnormal sample according to the 3σ rule. If it is judged to be yes, perform cleaning, if it is ju...

Embodiment 3

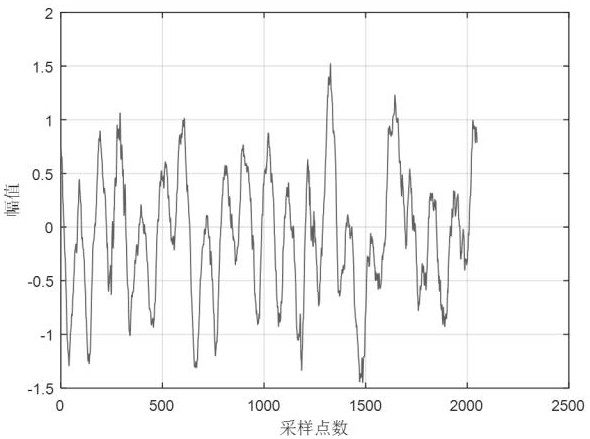

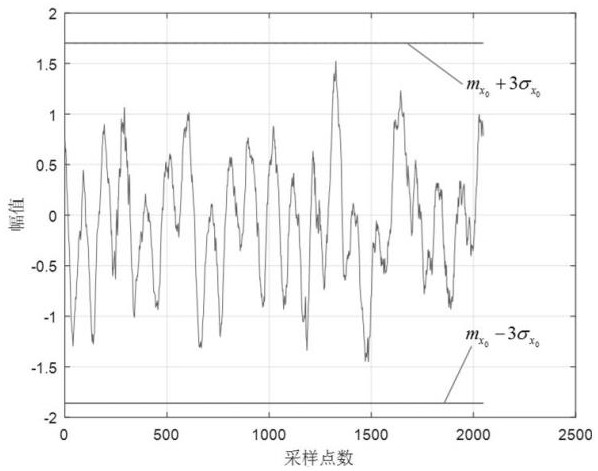

[0143] A vibration data cleaning method based on interval standard deviation combined with spectrum analysis, comprehensively judges whether the sample is an abnormal sample point through probability statistics and spectrum correlation analysis (assuming that the number of sampling points of the sample is L = 2048, and the sampling frequency is 2.56KHz ): . Given a correlation coefficient threshold .

[0144] (1) Calculate the original sample X standard deviation: ;

[0145] (2) Set interval points according to the equipment rotation speed: In this example, assuming that the equipment rotation speed is 3000 rpm, the corresponding multiplier frequency of the equipment is 3000 / 60=50Hz. According to the vibration signal sampling frequency of 2.56k Hz, the calculated data length of one period of the signal is: N = 2.56*1000 / 50 ≈ 51;

[0146] (3) Divide the original sample into 40 intervals ( L / N = 2048 / 51 ≈ 40 In order to ensure the timeliness of calculation, adjacent int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com