Method for repairing dead pixels of four-primary-color display screen

A repair method and four-primary color technology, applied in static indicators, instruments, identification devices, etc., can solve the problems of increased redundancy, poor scalability, and no consideration of pixel color gamut compensation where dead pixels are located, so as to achieve the best true color. degree, the effect of expanding the display color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A method for repairing dead pixels of a four-primary-color display screen of the present invention will be further described below in combination with embodiments and drawings. In the description of the present invention, it should be understood that the terms "first" and "second" are used for description purposes only, and do not have the function of illustrating the relative importance or the quantity of the technical features.

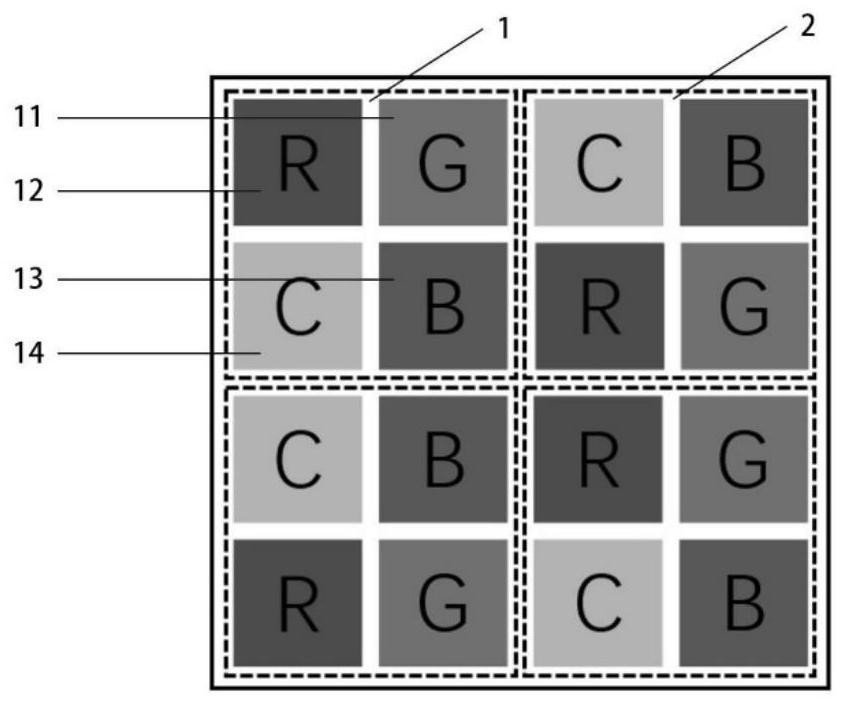

[0037] figure 1 It is a pixel arrangement structure diagram of a four-primary-color display screen provided by the present invention. The first pixel unit 1 is composed of four colors: 11 green sub-pixels, 12 red sub-pixels, 13 blue sub-pixels, and 14 cyan sub-pixels. The arrangement of the internal sub-pixels of the second pixel unit 2 is obtained by swapping the red sub-pixels and the cyan sub-pixels, and the green sub-pixels and the blue sub-pixels in the first pixel unit. The periodic arrangement of the first pixel unit 1 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com