Artificial lens

An intraocular lens and single-body technology, applied in the direction of intraocular lens, eye implants, etc., can solve problems such as complex calculation, achieve the effect of easy lens color, meet the needs of customization, and reduce the requirements of production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

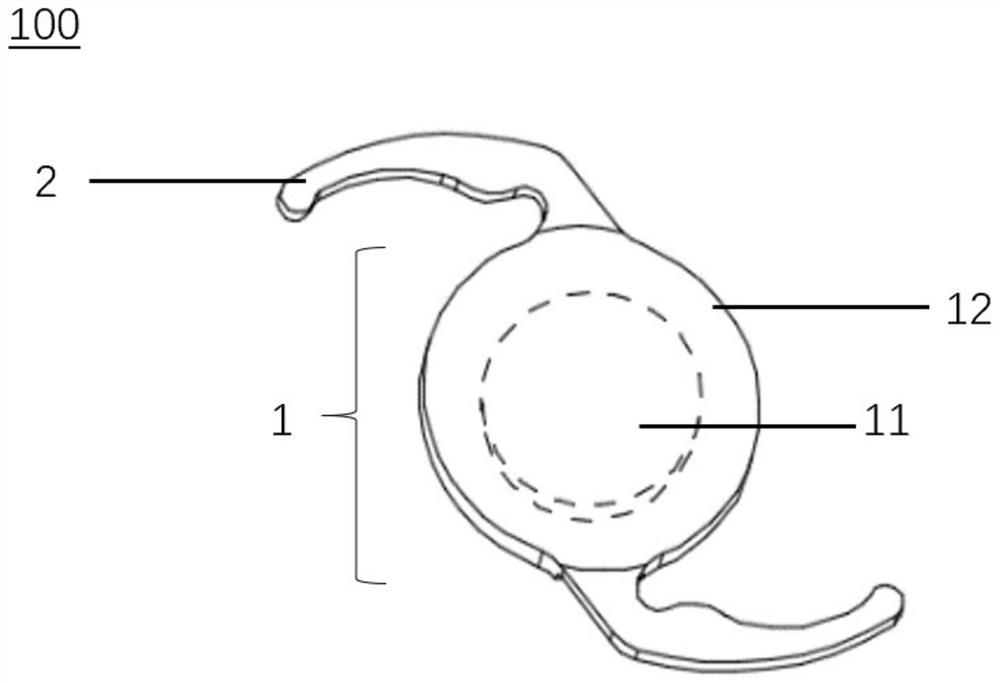

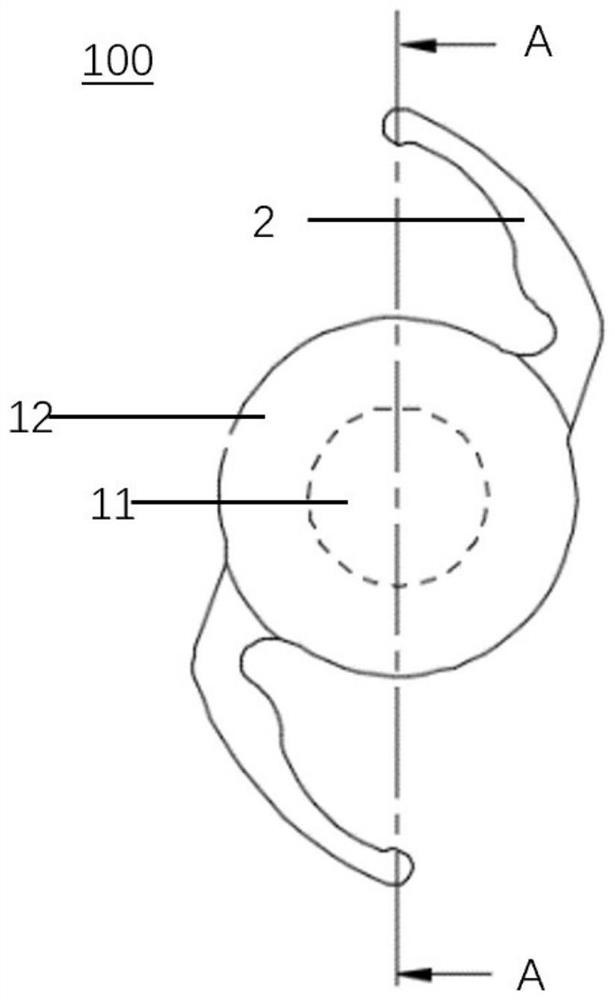

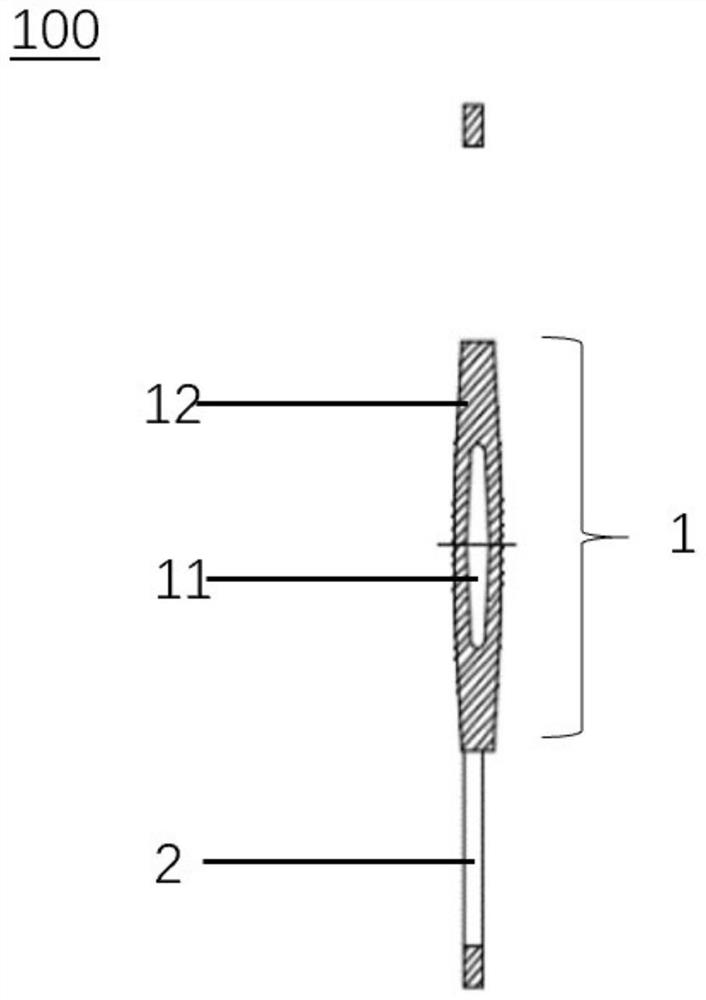

[0069] The multifocal intraocular lens of the present invention is polymerized from two polymeric materials each having a different refractive index.

[0070] First the inner lens polymer material is prepared. Add Ph-A, n-BuA, TFE-MA, TFE-A, EGDMA, Norbloc7966, and AIBN in the following amounts to a glass bottle with a capacity of 10 mL, and stir at room temperature for 20 hours to obtain a polymer mixture for inner lenses.

[0071] Ph-A: 15g (15% by mass, 13% by mole)

[0072] n-BuA: 28g (28% by mass, 33.4% by mole)

[0073] TFE-MA: 35g (35% by mass, 31.8% by mole)

[0074] TFE-A: 22g (22 mass%, 21.8 mol%)

[0075] EGDMA: 2g (2% by mass relative to the total amount of Ph-A, n-BuA, TFE-MA, and TFE-A)

[0076] Norbloc7966: 0.4g (0.4% by mass relative to the total amount of Ph-A, n-BuA, TFE-MA, and TFE-A)

[0077] AIBN: 0.3g (0.3% by mass relative to the total amount of Ph-A, n-BuA, TFE-MA, and TFE-A)

[0078] Figure 4 The mold for the inner lens is shown. The mold is m...

Embodiment 2

[0100] The manufacturing process of the multifocal intraocular lens composed of two polymers with different ultraviolet visible transmittances will be described below.

[0101] In the same manner as in Example 1, first, an inner lens polymer material was prepared. Add Ph-MA, Ph-A, n-BuA, TFE-MA, BL01, EGDMA, Norbloc7966, and AIBN in the following amounts to a glass bottle with a capacity of 10 mL, and stir at room temperature for 20 hours to prepare a polymer for inner lenses Mixture.

[0102] Ph-MA: 24g (24% by mass, 22.1% by mole)

[0103] Ph-A: 64g (64 mass%, 63.7 mol%)

[0104] n-BuA: 5g (5% by mass, 6.8% by mole)

[0105] TFE-MA: 7g (7% by mass, 7.3% by mole)

[0106] BL01: 0.02 g (0.02% by mass relative to the total amount of Ph-MA, Ph-A, n-BuA, and TFE-MA)

[0107] EGDMA: 2g (2% by mass relative to the total amount of Ph-MA, Ph-A, n-BuA, and TFE-MA)

[0108] Norbloc7966: 1.5 g (0.4% by mass relative to the total amount of Ph-MA, Ph-A, n-BuA, and TFE-MA)

[0109] ...

Embodiment 3

[0121] The fabrication process of the multifocal intraocular lens composed of two photochromic polymers will be described below.

[0122] Photochromic materials change color by exposure to light and become transparent in dark places. So if it's used in an intraocular lens material, it could function like an iris. Its optical performance is similar to that of a camera's aperture, which controls the amount of light by changing the aperture. The photochromic material can control the light by changing the transmittance of the lens. The principles of the two are different, but the technical effects that can be achieved are the same.

[0123] Previous photochromic intraocular lenses were made of homogeneous materials, so the intensity of color was different in lenses of different powers and thicknesses. But by using the manufacturing method of the present invention, the color density of the intraocular lens can be kept consistent in all sizes and in all optical performance ranges...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com