A high toughness and high wear resistance wire for additive manufacturing of hot work molds and preparation method thereof

A high wear-resistance, hot-work mold technology, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of complex process and long time-consuming, achieve simple process, reduce non-metallic inclusions, and dense matrix structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

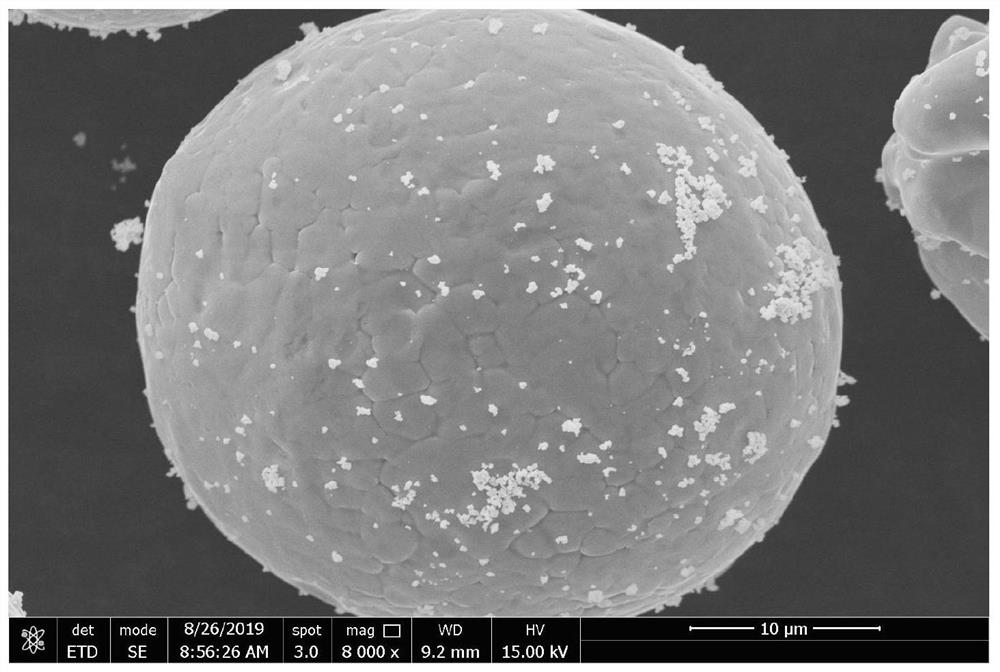

[0024]A wire suitable for additive manufacturing of hot work molds, using H08A steel strip as the sheath, the size of the steel strip is 0.7×14mm, the powder filling rate is 28.0%, and the diameter of the wire is 1.2mm. The composition and mass percentage of the drug core powder are as follows: alloy powder: Cr: 4.0%, Mo: 1.5%, V: 0.5%, Nb: 4.0%; Co: 2.0%; combined deoxidizer: Zr: 0.5%, Si : 0.5%; Sc: 0.5%; Nano WC: 1.5%, the balance is iron powder. The particle size range of the alloy powder is 100-150 μm, the particle size range of the nanometer WC is 80-100 nm, and the purity is 99.9%.

[0025] The specific steps of the wire preparation method are as follows:

[0026] S1: First, add 500g of atomized iron powder with a particle size of 450-500μm into 10L of ethanol solution, stir for 30min, then add 50ml of 3-aminopropyltriethoxysilane, continue stirring for 1h, then vacuum filter Atomized iron powder with positive charge on the surface is obtained. Under the condition of...

Embodiment 2

[0030] A wire suitable for additive manufacturing of hot work molds, using H08A steel strip as the outer skin, the size of the steel strip is 0.7×14mm, the powder filling rate is 30.0%, and the diameter of the wire is 1.6mm. The composition and mass percentage of the drug core powder are as follows: alloy powder: Cr: 4.0%, Mo: 1.5%, V: 0.5%, Nb: 4.5%; Co: 3.0%; combined deoxidizer: Zr: 0.5%, Si : 0.5%; Sc: 0.5%; Nano WC: 3.0%, the balance is iron powder. The particle size range of the alloy powder is 100-150 μm, the particle size range of the nanometer WC is 80-100 nm, and the purity is 99.9%.

[0031] The specific steps of the wire preparation method are as follows:

[0032] S1: First, add 500g of atomized iron powder with a particle size of 450-500μm into 10L of ethanol solution, stir for 30min, then add 50ml of 3-aminopropyltriethoxysilane, continue stirring for 1h, then vacuum filter Atomized iron powder with positive charge on the surface is obtained. Under the conditi...

Embodiment 3

[0036] A wire suitable for additive manufacturing of hot work molds, using H08A steel strip as the outer skin, the size of the steel strip is 0.7×14mm, the powder filling rate is 30.0%, and the diameter of the wire is 1.6mm. The composition and mass percentage of the drug core powder are as follows: alloy powder: Cr: 4.0%, Mo: 1.5%, V: 0.5%, Nb: 5.0%; Co: 4.0%; combined deoxidizer: Zr: 0.5%, Si : 0.5%; Sc: 0.5%; Nano WC: 4.0%, the balance is iron powder. The particle size range of the alloy powder is 100-150 μm, the particle size range of the nanometer WC is 80-100 nm, and the purity is 99.9%.

[0037] The specific steps of the wire preparation method are as follows:

[0038] S1: First, add 500g of atomized iron powder with a particle size of 450-500μm into 10L of ethanol solution, stir for 30min, then add 50ml of 3-aminopropyltriethoxysilane, continue stirring for 1h, then vacuum filter Atomized iron powder with positive charge on the surface is obtained. Under the conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com