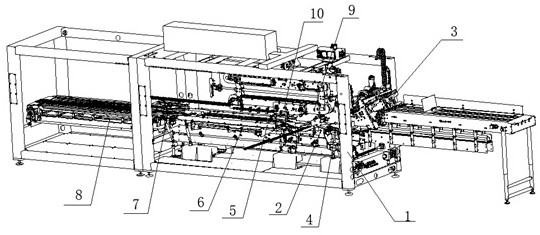

High-speed full-automatic servo paperboard packaging machine

A fully automatic, paper-wrapped technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of complex machine structure, poor versatility, poor operability, etc., achieve safe and reliable protection devices, and shorten the conversion time , The effect of simplifying the mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Before the machine is started, the operator loads the cardboard into the conveyor table and cardboard magazine of the cardboard conveyor.

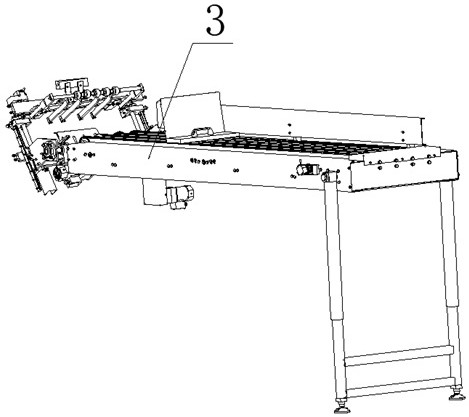

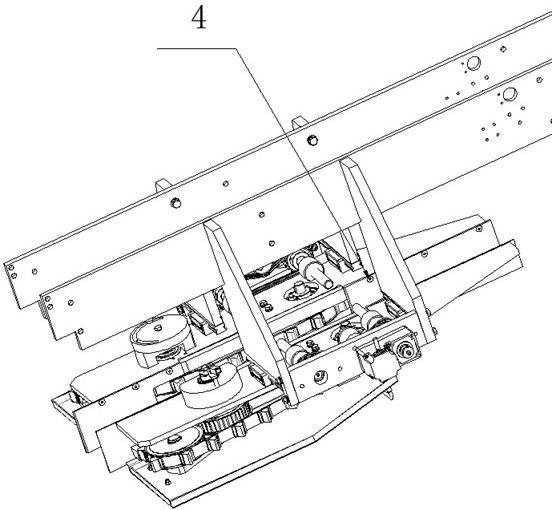

[0032] When the equipment is started, the cardboard suction device sucks the cardboard out of the cardboard bin, and sends the cardboard to the paper push chain through the conveying wheel in the cardboard feeding mechanism. The can feeding timing belt under the cardboard feeding and feeding mechanism is set synchronously with the paper pushing chain, and the product and cardboard are synchronously fed to the bottom of the top chain mechanism. The edger component mechanism, the edger mechanism folds the leading triangle edge and the trailing triangle edge of the cardboard into shape, then the product and the cardboard enter the pin chain synchronously, the pins on the pin chain support the product, and the pins fix the cardboard at the same time The cardboard is sent to the lock box mechanism placed in the middle of the pin chain as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com