High-strength and high-toughness aluminum alloy for rail transit and production process

A rail transit, high-strength and high-toughness technology, applied in the field of aluminum alloy materials, can solve problems such as dissatisfaction, and achieve the effects of reducing structural defects, reducing secondary crystal spacing, and improving quenching sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

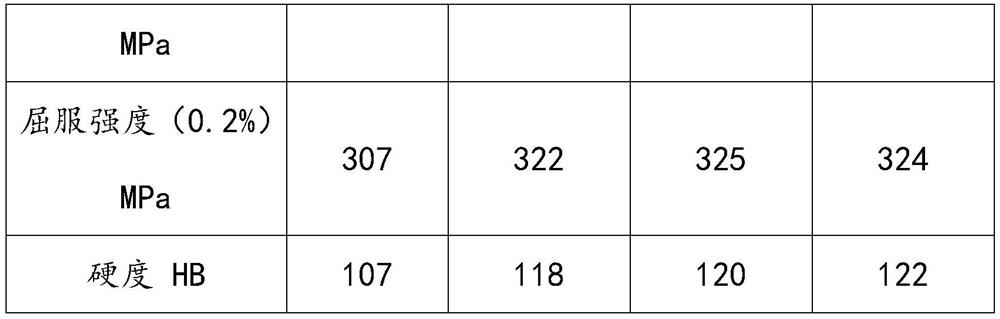

Embodiment 1

[0033] A high-strength and high-toughness aluminum alloy for rail transit, according to the mass percentage, the element composition of the aluminum alloy product is: Si: 0.70%; Mg: 0.90%; Cu: 0.20%; Cr: 0.10%; Mn: 0.21%; Zr: 0.13%; Y: 0.04%; Ti: 0.04%; the balance is Al and unavoidable impurities.

[0034] In addition, the present invention also provides a production process of the above-mentioned high-strength and high-toughness aluminum alloy for rail transit, and the preparation process of the aluminum alloy includes the following steps:

[0035] (1) Calculate the quality of each raw material according to the element formula, add electrolytic aluminum liquid into the furnace, control the temperature of the aluminum liquid to 755-765 °C, and then add Si: 0.70%; Cu: 0.20%; Cr: 0.10%; Mn: 0.21%; Zr: 0.13%; Y: 0.04%; Ti: 0.04%, stirring and melting into aluminum alloy liquid;

[0036] (2) Stir the aluminum alloy liquid magnetically for 13 minutes, then let it stand for 8 minu...

Embodiment 2

[0053] A high-strength and high-toughness aluminum alloy for rail transit, according to the mass percentage, the element composition of the aluminum alloy product is: Si: 0.90%; Mg: 1.20%; Cu: 0.40%; Cr: 0.16%; Mn: 0.26%; Zr: 0.18%; Y: 0.08%; Ti: 0.07%; the balance is Al and unavoidable impurities.

[0054] In addition, the present invention also provides a production process of the above-mentioned high-strength and high-toughness aluminum alloy for rail transit, and the preparation process of the aluminum alloy includes the following steps:

[0055] (1) Calculate the mass of each raw material according to the element formula, add electrolytic aluminum liquid into the furnace, control the temperature of the aluminum liquid to 765°C, and then add Si: 0.90%; Cu: 0.40%; Cr: 0.16%; Mn: 0.26% ; Zr: 0.18%; Y: 0.08%; Ti: 0.07%, stirring and melting into aluminum alloy liquid;

[0056] (2) Stir the aluminum alloy liquid magnetically for 15 minutes, then let it stand for 10 minutes, t...

Embodiment 3

[0073] A high-strength and high-toughness aluminum alloy for rail transit, according to the mass percentage, the element composition of the aluminum alloy product is: Si: 0.80%; Mg: 0.10%; Cu: 0.30%; Cr: 0.13%; Mn: 0.23%; Zr: 0.15%; Y: 0.06%; Ti: 0.06%; the balance is Al and unavoidable impurities.

[0074] In addition, the present invention also provides a production process of the above-mentioned high-strength and high-toughness aluminum alloy for rail transit, and the preparation process of the aluminum alloy includes the following steps:

[0075] (1) Calculate the mass of each raw material according to the element formula, add electrolytic aluminum liquid into the furnace, control the temperature of the aluminum liquid to 765°C, and then add Si: 0.80%; Cu: 0.30%; Cr: 0.13%; Mn: 0.23% ; Zr: 0.15%; Y: 0.06%; Ti: 0.06%, stirring and melting into aluminum alloy liquid;

[0076] (2) Magnetically stir the aluminum alloy liquid for 14 minutes, then stir again after standing stil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com