Bulked yarn and preparation method thereof

A technology of bulked yarn and melt, which is applied in the manufacture of yarn, rayon, textiles and paper, etc. It can solve the problems affecting the aesthetics of carpets, fading and aging, cross-infection, etc., achieve great economic value and social significance, and reduce energy consumption The effect of using and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

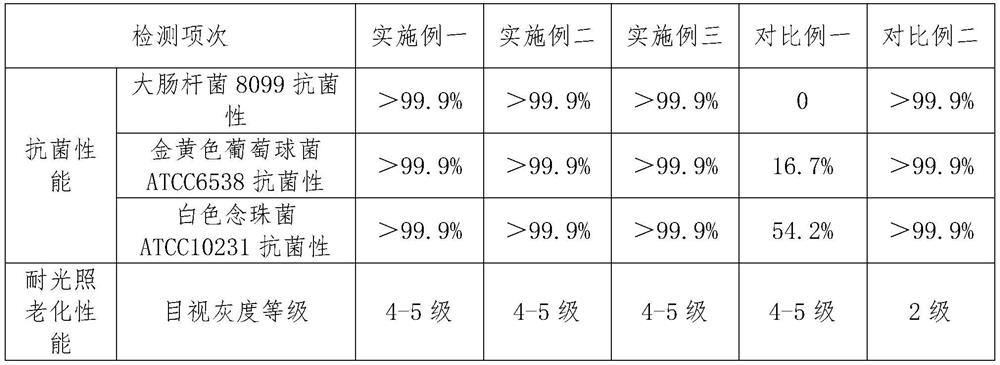

Examples

Embodiment 1

[0027] Embodiment 1 of the present invention provides a bulked yarn, which is prepared according to the following method:

[0028] Step 1: Mix and melt, measure and mix each raw material, use recycled PA6 slices for recycled plastic, accounting for 85-94%wt, color masterbatch accounting for 2-5%wt, antibacterial material accounting for 2-5%wt, The UV stabilizer accounts for 2-5%wt. The raw materials are mixed, and the mixed materials are melted and mixed in a screw extruder at 250-280°C to obtain a mixed melt; among them, recycled PA6 materials can come from waste Fishing net silk, waste carpet yarn and other materials, the carrier of the masterbatch is PA6 slices, the antibacterial material is a silver ion complex antibacterial agent, the carrier is PA6 slices, and the UV stabilizer is hindered amine light stabilizer. The carrier is also a PA6 slice;

[0029] Step 2: spinning, the mixed melt in step 1 is transported to the spinning box under the pressure of 70-110bar through...

Embodiment 2

[0039] Embodiment 2 of the present invention provides a bulked yarn, which is prepared according to the following method:

[0040] Step 1: Mix and melt, measure and mix each raw material, use recycled PP slices for recycled plastics, accounting for 85-94%wt, color masterbatch accounting for 2-5%wt, antibacterial materials accounting for 2-5%wt, The UV stabilizer accounts for 2-5%wt. The raw materials are mixed, and the mixed materials are melted and mixed in a screw extruder at 200-255°C to obtain a mixed melt; among them, recycled PP materials can come from waste For PP products, the carrier of the masterbatch is PP slices, the antibacterial material is a silver ion complex antibacterial agent, the carrier is PP slices, the UV stabilizer is hindered amine light stabilizer, and the carrier is also PP slices;

[0041] Step 2: spinning, the mixed melt in step 1 is transported to the spinning box under the pressure of 70-110bar through the metering pump, and the spinning melt pas...

Embodiment 3

[0051] Embodiment 3 of the present invention provides a bulked yarn, which is prepared according to the following method:

[0052] Step 1: Drying and crystallization, recycled plastics are made of recycled PET slices, accounting for 85-94%wt, masterbatches accounting for 2-5%wt, antibacterial materials accounting for 2-5%wt, UV stabilizers accounting for 2-5%wt 5%wt, the recycled PET is continuously dried and crystallized, the drying time is ≥12h, the dry air dew point is ≤-80°C, the drying temperature is 160-175°C, the crystallization temperature is 160-175°C, and the water content of the recycled PET slices after drying is lower than 30ppm; Among them, recycled PET materials can come from waste materials such as plastic bottles and mineral water bottles. The carrier of the masterbatch is PET slices. The antibacterial material is an antibacterial agent containing silver ion complexes. A hindered amine light stabilizer is selected as the agent, and its carrier is also a PET ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com