A profile measuring device and method for multi-cone deep hole parts

A technology of measuring device and cone segment, which is applied in the direction of measuring device, optical device, instrument, etc., can solve the problems of difficult measurement, poor measurement accuracy, stuck deep hole parts, etc., and achieves simple and compact overall structure and good overall structure rigidity. , The effect of high axial feed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

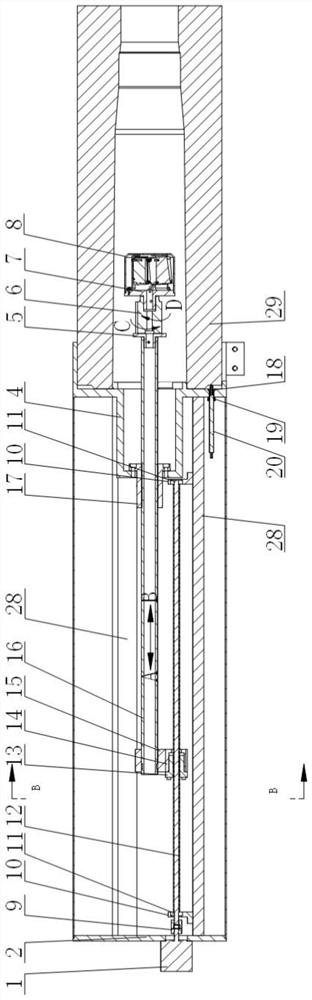

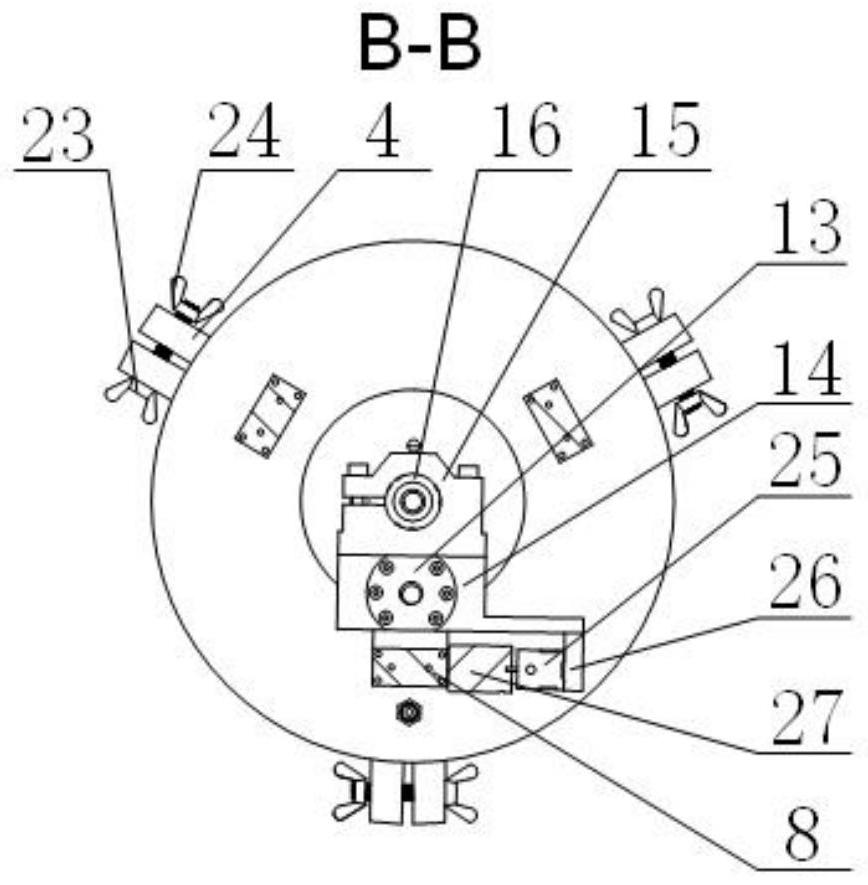

[0029] The specific implementation of the present invention will be described in detail below in conjunction with the drawings and technical solutions.

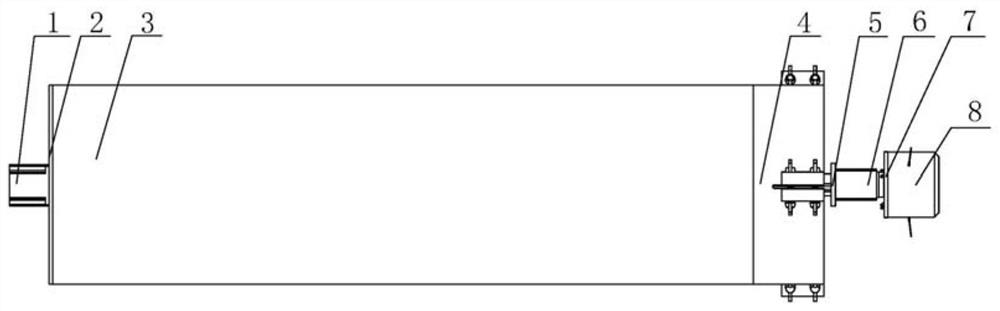

[0030] like Figure 1~4 As shown, 1. A profile measuring device for multi-cone section deep hole parts, including a cavity, an axial feed mechanism, an axial detection mechanism, an aperture measurement mechanism and a drive motor 1, and the drive motor 1 is installed in the cavity The left side of the body; the axial feed mechanism, the axial detection mechanism and the aperture measurement mechanism are respectively installed inside the cavity, the output shaft of the drive motor 1 passes through the left end cover 2 of the cavity, and is connected to the cavity through the coupling 9 Lead screw connection for axial feed mechanism. Therefore, the axial feed of the axial feed mechanism drives the axial detection mechanism to realize axial position detection, and also drives the aperture measurement mechanism to move axially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com