Non-woven fabric flaw detection and classification method and system based on machine vision

A defect detection and machine vision technology, applied in the field of non-woven defect detection and classification methods and systems, can solve the problems of large amount of calculation, poor real-time performance, and failure to segment defects, etc., to achieve small amount of calculation, high accuracy, and reduce redundancy. The effect of residual information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, according to the description in this document, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments.

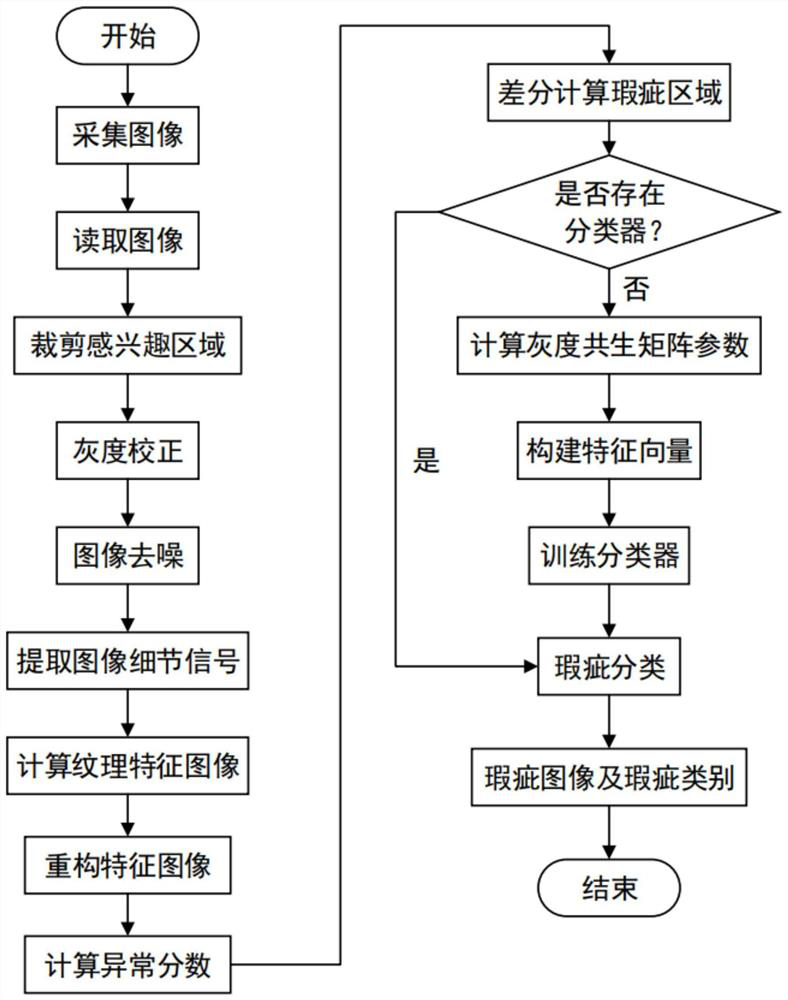

[0052] Examples of the present invention are as follows, refer to figure 1 , a non-woven fabric defect detection and classification method based on machine vision, comprising the following steps:

[0053] (1) Image collection: collect images of non-woven fabrics;

[0054] (2) Image preprocessing;

[0055] (3) Extracting image detail signals: using wavelet transform to analyze and extract detail signals of non-woven fabric defect images;

[0056] (4) Calculate the texture feature image and reconstruct the feature image: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com