Filtering assembly and forming method thereof

A component and light-shielding layer technology, which is applied in the field of fingerprint recognition, can solve the problems that the filter components need to be improved, and achieve the effect of improving the quality of optical signals and reducing crosstalk optical signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

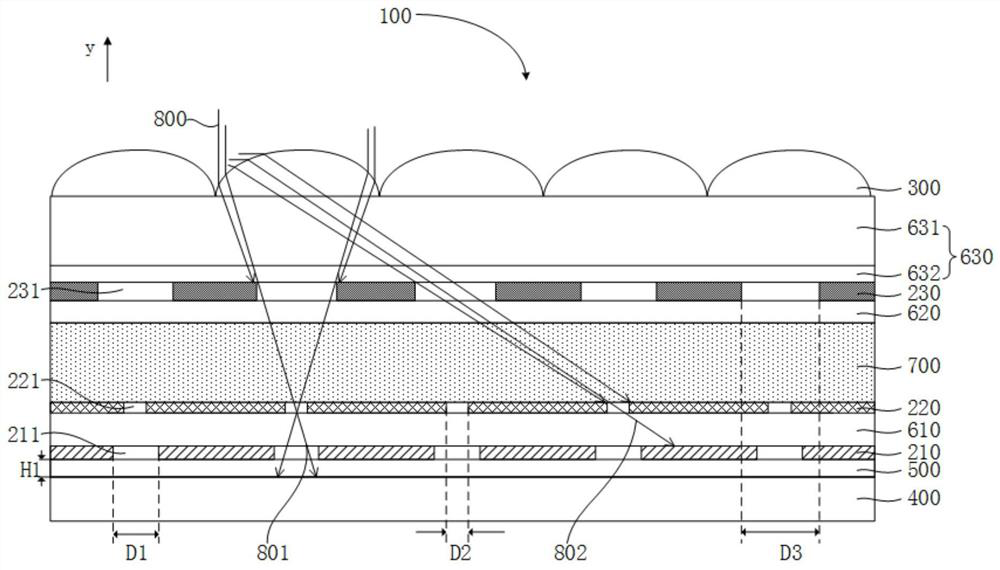

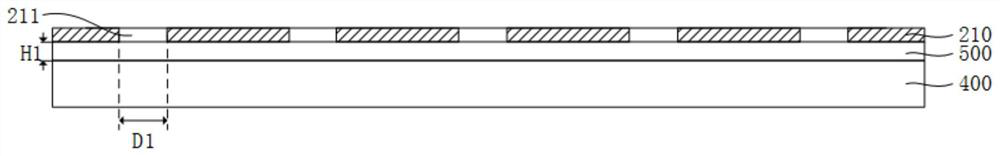

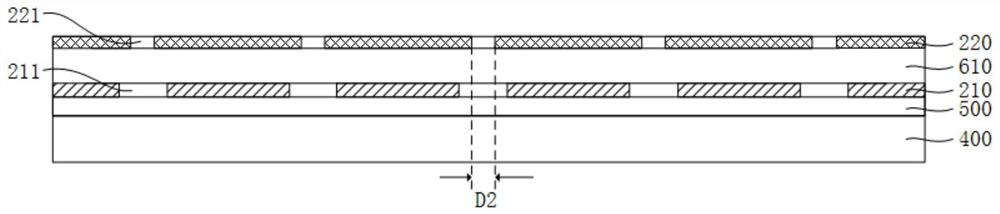

[0042] The analysis is now combined with an optical filter assembly, the optical filter assembly includes: a light-shielding layer with a plurality of first through holes in the light-shielding layer; a light-absorbing layer, the light-absorbing layer is located on the light-shielding layer, the There are a plurality of second through holes in the light absorbing layer, and the second through holes correspond to the first through holes one by one. The light-shielding layer can filter out part of the light output by the second through hole with a large inclination angle, but part of the light output by the third through hole of the light absorbing layer can be filtered due to the large inclination angle of the light direction. Passing through the adjacent or farther second through holes, so that the light emitted by the second through holes includes crosstalk light signals, resulting in poor quality of the light signals emitted by the second through holes and affecting the image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com