Gas diffusion layer for proton exchange membrane fuel cell and preparation method thereof

A technology of gas diffusion layer and proton exchange membrane, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of reduced mechanical and conductive functions, uneven distribution, and complicated preparation process, so as to reduce coating preparation and prevent water pollution. Flooding phenomenon, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

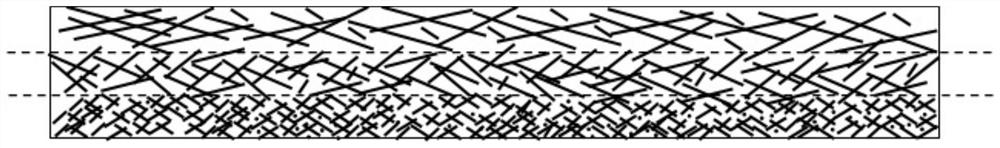

Image

Examples

Embodiment 1

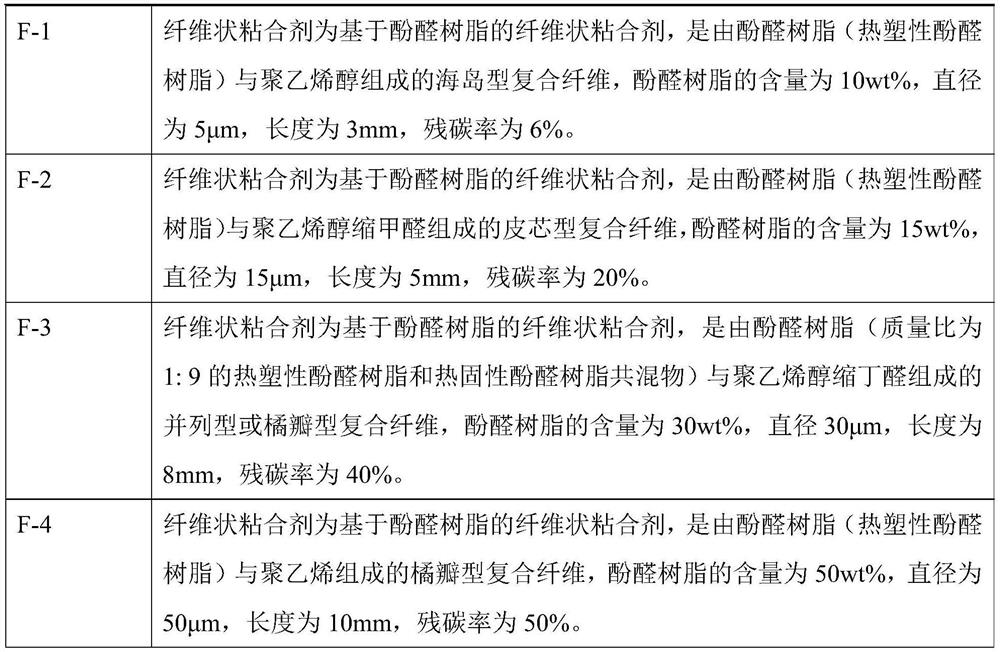

[0057] A fibrous adhesive is prepared by the method of melt blending and spinning, and the specific steps are as follows:

[0058] (1) phenolic resin (thermoplastic phenolic resin) and polyethylene are charged into the screw and melted to obtain a well-mixed phenolic resin / polyethylene melt;

[0059](2) the melt is extruded through the spinneret hole to form a thin stream of melt;

[0060] (3) The melt stream is cooled and solidified to form primary fibers;

[0061] (4) The spun fiber is oiled and wound to obtain a blended fiber.

[0062] The content of the phenolic resin in the prepared fibrous adhesive is 10 wt %, the diameter of the fibrous adhesive is 10 μm, the length is 7 mm, and the carbon residue rate is 10%.

Embodiment 2

[0064] A fibrous adhesive is prepared by the method of melt blending and spinning, and the specific steps are as follows:

[0065] (1) phenolic resin (thermosetting phenolic resin) and polypropylene are charged into the screw and melted to obtain a well-mixed phenolic resin / polypropylene melt;

[0066] (2) the melt is extruded through the spinneret hole to form a thin stream of melt;

[0067] (3) The melt stream is cooled and solidified to form primary fibers;

[0068] (4) The spun fiber is oiled and wound to obtain a blended fiber.

[0069] The content of phenolic resin in the prepared fibrous adhesive is 20 wt %, the diameter of the fibrous adhesive is 20 μm, the length is 5 mm, and the carbon residue rate is 30%.

Embodiment 3

[0071] A fibrous adhesive is prepared by the method of melt blending and spinning, and the specific steps are as follows:

[0072] (1) phenolic resin (mass ratio of 9:1 thermoplastic phenolic resin and thermosetting phenolic resin blend) and polyethylene are charged into screw and melted to obtain homogeneously mixed phenolic resin / polyethylene melt;

[0073] (2) the melt is extruded through the spinneret hole to form a thin stream of melt;

[0074] (3) The melt stream is cooled and solidified to form primary fibers;

[0075] (4) The spun fiber is oiled and wound to obtain a blended fiber.

[0076] The content of the phenolic resin in the prepared fibrous adhesive is 30 wt %, the diameter of the fibrous adhesive is 27 μm, the length is 8 mm, and the carbon residue rate is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com