Miniaturized heavy-load solid-state relay

A solid-state relay, large-load technology, applied in the direction of logic circuits using optoelectronic equipment, logic circuits using specific components, etc., can solve the problems of weak photovoltaic driving capability, limited parallel connection, and small photovoltaic driving current, etc., to meet the requirements of equipment miniaturization. , the overall volume miniaturization, the effect of reducing product volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

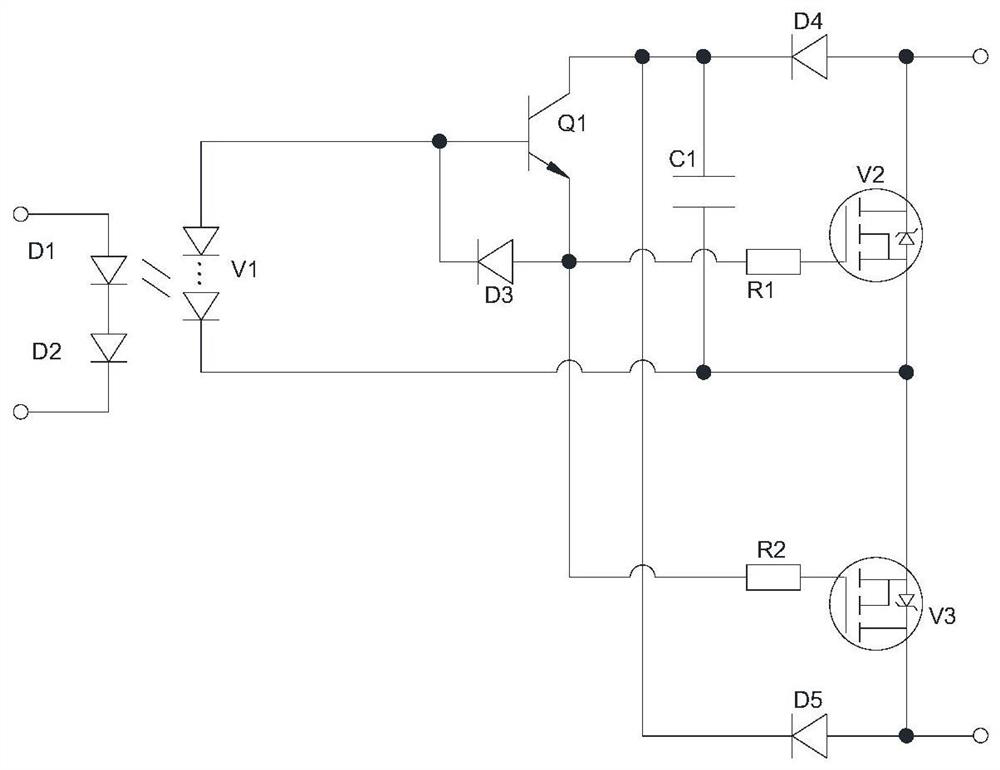

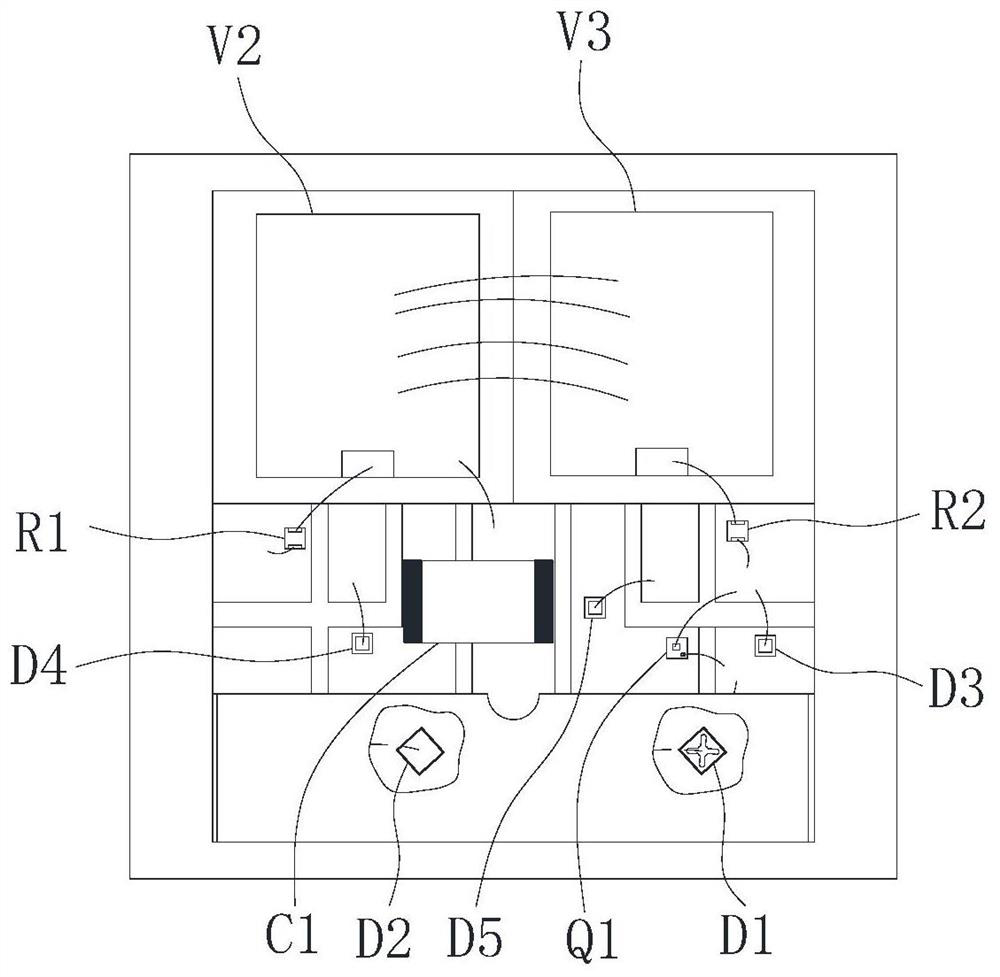

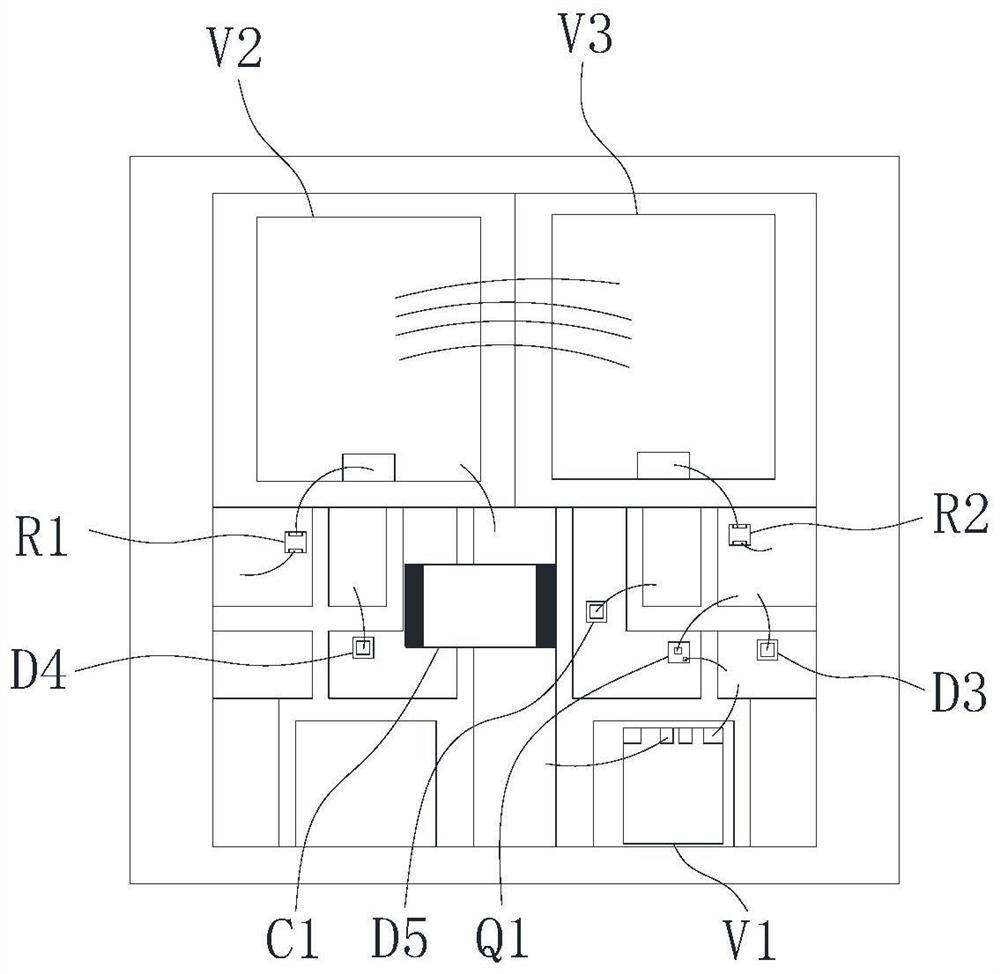

[0037] A solid-state relay with miniaturization and large load. In order to achieve fast on-off and improve driving capability, its driving circuit is as follows: figure 1 As shown, it consists of light-emitting diode D1, switching diodes D2, D3, D4 and D5, photovoltaic V1, transistor Q1, capacitor C1, resistors R1, R2, and MOS chips V2 and V3. Light-emitting diode D1 is connected to the input power supply for photovoltaic V1. The light drive signal, the output anode of the photovoltaic V1 is connected to the source of the MOS chip V2, the drain of the MOS chip V2 is connected to the anode of the switching diode D4, and a capacitor C1 is connected in parallel between the cathode of the switching diode D4 and the source of the MOS chip V2. The cathode of the switching diode D4 is connected to the collector of the transistor Q1, the base of the transistor Q1 is connected to the output cathode of the photovoltaic V1, a resistor R1 is connected in series between the gate of the MOS c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com