Micro-nano silk fibroin-induced bone mineralization calcium phosphate-based bone cement and preparation method thereof

A technology of silk fibroin and calcium phosphate, which is applied in the field of biomedical materials, can solve problems such as limitations, slow degradation speed, and low mechanical properties, and achieve good self-curing properties, promote adhesion, and promote the effects of mineral deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

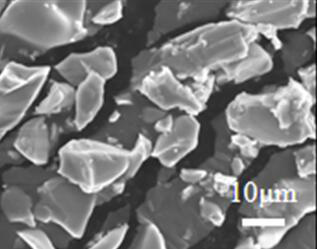

[0026] Preparation of α-calcium sulfate hemihydrate: Put 80 g calcium sulfate dihydrate in a closed autoclave, heat to 120°C, the pressure is about 0.138MPa at this time, keep the pressure and heat at constant temperature for 9 hours. After that, the material was taken out and placed in an oven at 110°C to dry for 2 hours, then cooled and ground, and sieved through a 200-mesh sieve to obtain α-calcium sulfate hemihydrate powder with uniform particle size.

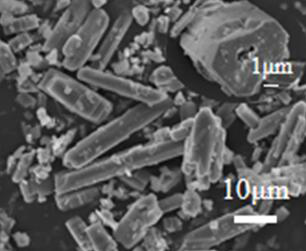

[0027] Preparation of α-tricalcium phosphate: react 1000ml 0.26mol / L phosphoric acid solution with 0.13mol calcium carbonate for 1.5h to prepare solution C, slowly add solution C dropwise to 1000ml 0.13mol / L calcium hydroxide suspension , fully reacted for 4 hours to obtain suspension D; then added 0.13mol calcium carbonate and suspension D to react overnight, and obtained tricalcium phosphate precursor through aging, centrifugation, ball milling and other steps; after vacuum drying, sintering, grinding, Sieve and other ste...

Embodiment 2

[0033] The preparation of α-type calcium sulfate hemihydrate, drug-loaded silk fibroin microspheres, and mineralized silk fibroin nanofiber solutions is the same as in Example 1.

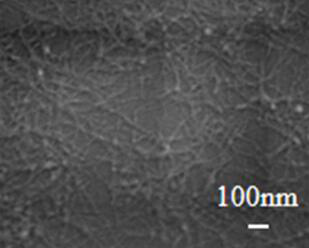

[0034] Mix 0.09g mineralized silk fibroin, 0.1455g α-calcium sulfate hemihydrate, and 2.7645g α-tricalcium phosphate, and add 1.2ml of 0.4wt% nano-silk fibroin fiber solution to prepare α-tricalcium phosphate / α-calcium sulfate hemihydrate / mineralized silk fibroin / nano silk fibrous bone repair material.

[0035] The final setting time of calcium phosphate-based bone cement materials induced by micro-nano silk fibroin in bone mineralization was 18min~20min, the compressive strength was 4.29MPa~6.62MPa, the average weight loss rate was 8.18% after 2 weeks of degradation, and the degradation rate was 4 The average weight loss rate after one week was 9.78%.

Embodiment 3

[0037] The preparation of α-type calcium sulfate hemihydrate, drug-loaded silk fibroin microspheres, and mineralized silk fibroin nanofiber solutions is the same as in Example 1.

[0038]Mix 0.09g mineralized silk fibroin, 0.291g α-calcium sulfate hemihydrate, and 2.619g α-tricalcium phosphate, and add 1.2ml of a 0.4wt% nano-silk fibroin fiber solution to prepare α-tricalcium phosphate / α-calcium sulfate hemihydrate / mineralized silk fibroin / nano silk fibrous bone repair material.

[0039] The final setting time of the calcium phosphate-based bone cement material induced by micro-nano silk fibroin in bone mineralization was 15min~18min, the compressive strength was 7MPa~7.25MPa, the average weight loss rate was 1.87% after 2 weeks of degradation, and the average weight loss rate was 1.87% after 4 weeks of degradation The average weight loss rate was 4.42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com