Two-stage-separation dust removal equipment and method thereof

A dust removal equipment and stage separation technology, applied in the field of two-stage separation dust removal equipment, can solve the problems of difficult separation of fine particles, high resistance of dust removal equipment, high energy consumption, etc., achieve effective recovery, reduce pressure drop loss, and increase separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

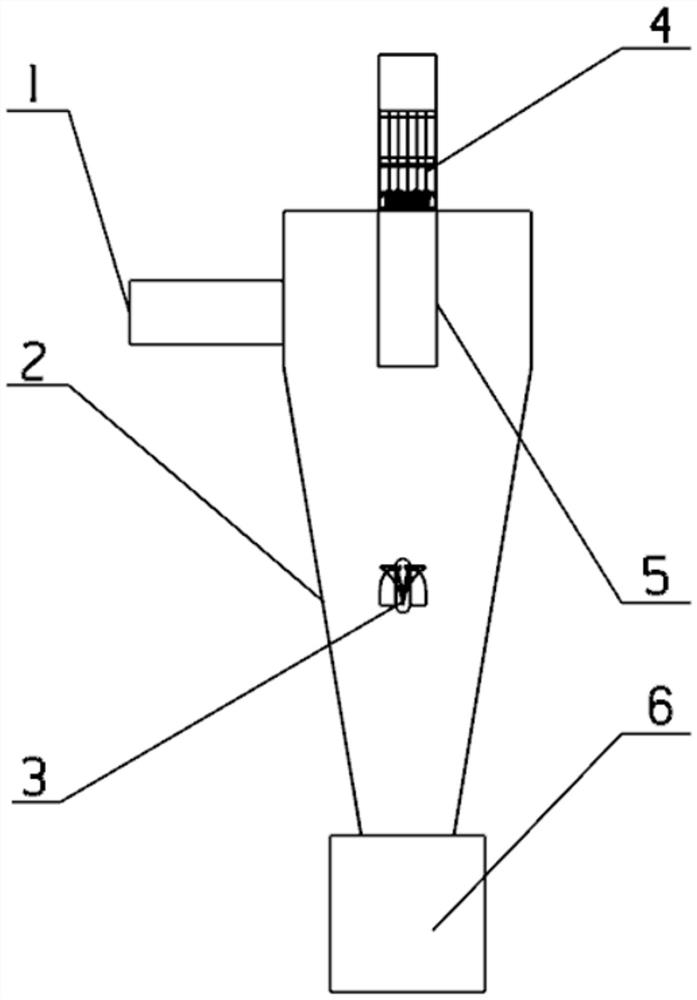

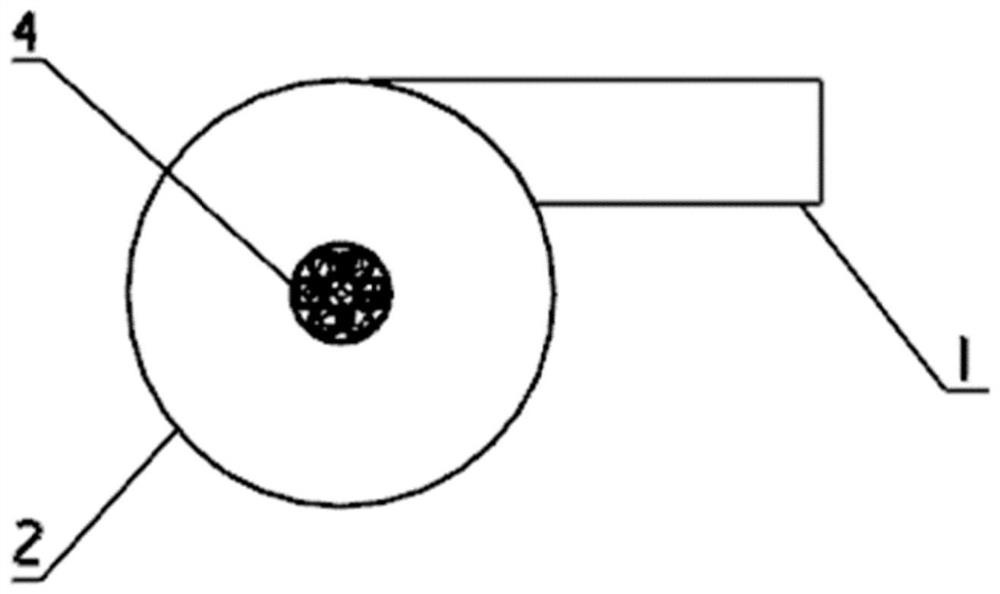

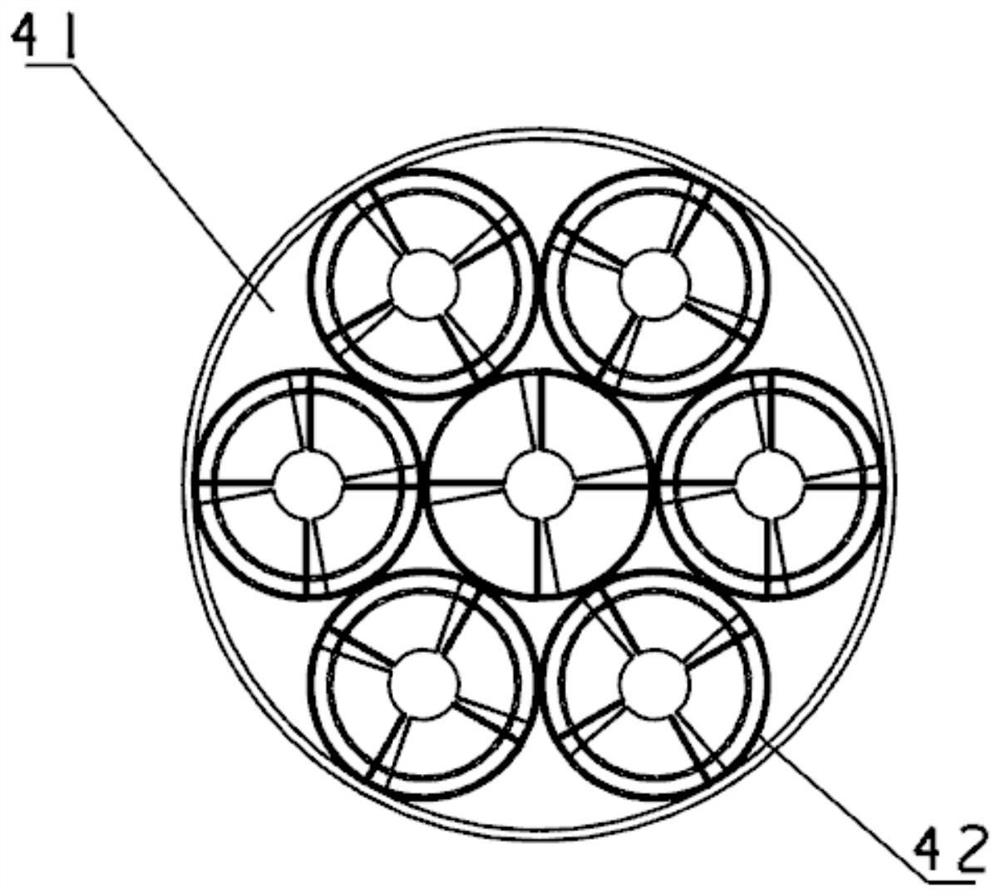

[0030] In order to make those skilled in the art understand the technical scheme of the present invention, below in conjunction with Figure 1-5 Do as follows.

[0031] A two-stage separation dedusting device and its method, comprising: a side air intake cylinder 1, a cyclone cylinder 2, a deflector 3, an array type swirl pipe 4, an internal exhaust pipe 5, and a dust collector 6; wherein, the array type The swirl tube 4 includes an outer cylinder 41 and a swirl tube unit 42 ; the swirl tube unit 42 includes a barrel unit 421 , a swirl sub-unit 422 , and a tail nozzle unit 423 .

[0032] The fluid that needs to be separated enters the side air inlet cylinder 1, and because the side air inlet cylinder 1 is tangent to the cyclone 2, the fluid produces high-speed rotational motion, most of the fluid flows in a spiral form around the inner wall of the side cyclone 2, and a small part The fluid moves downward around the inner exhaust pipe 5;

[0033] Most of the fluid flow starts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com