Spraying and line marking all-in-one machine and working method thereof

An all-in-one machine and nozzle technology, applied in the direction of the injection device, etc., can solve the problems such as the inability to apply the mold table and mold spraying and scribing marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

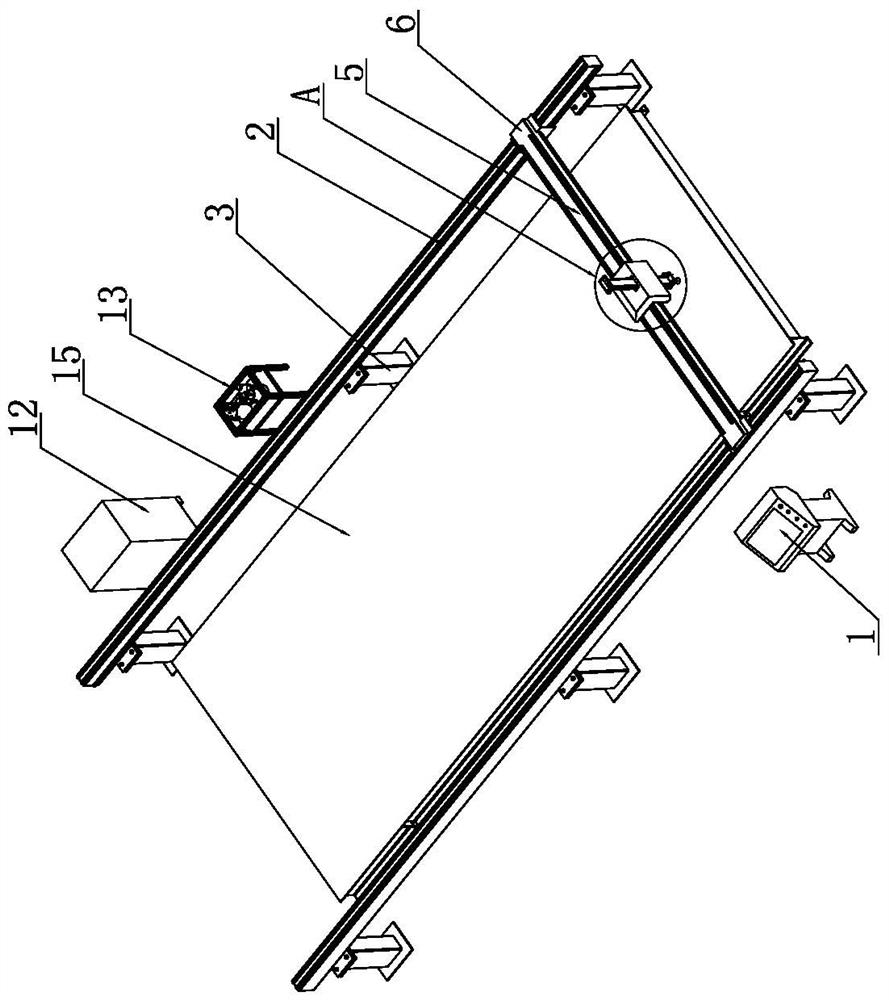

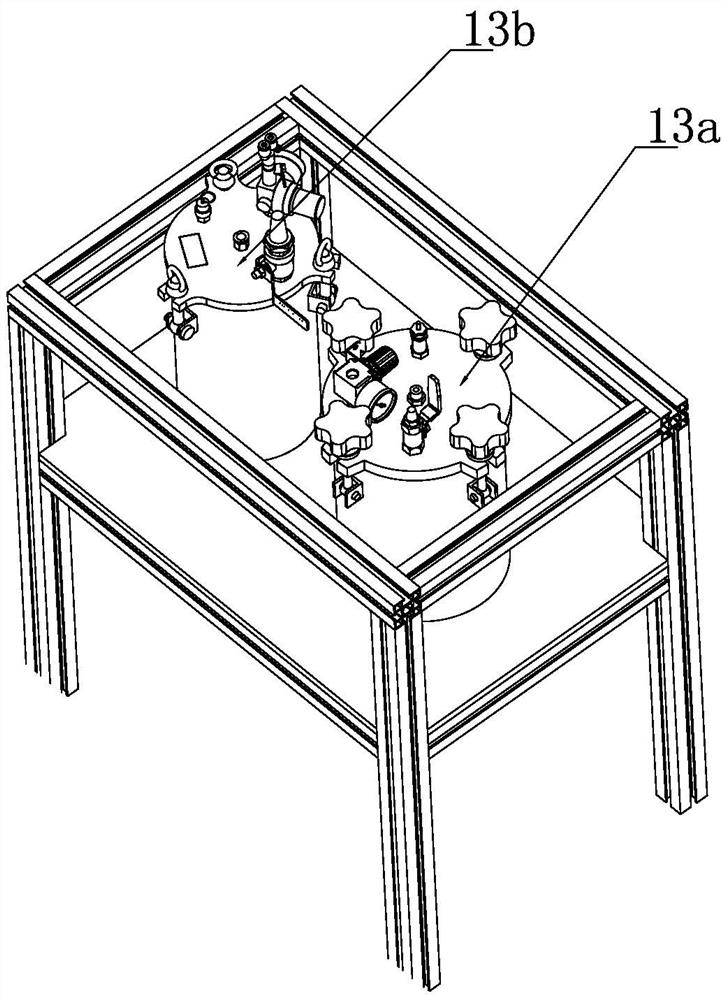

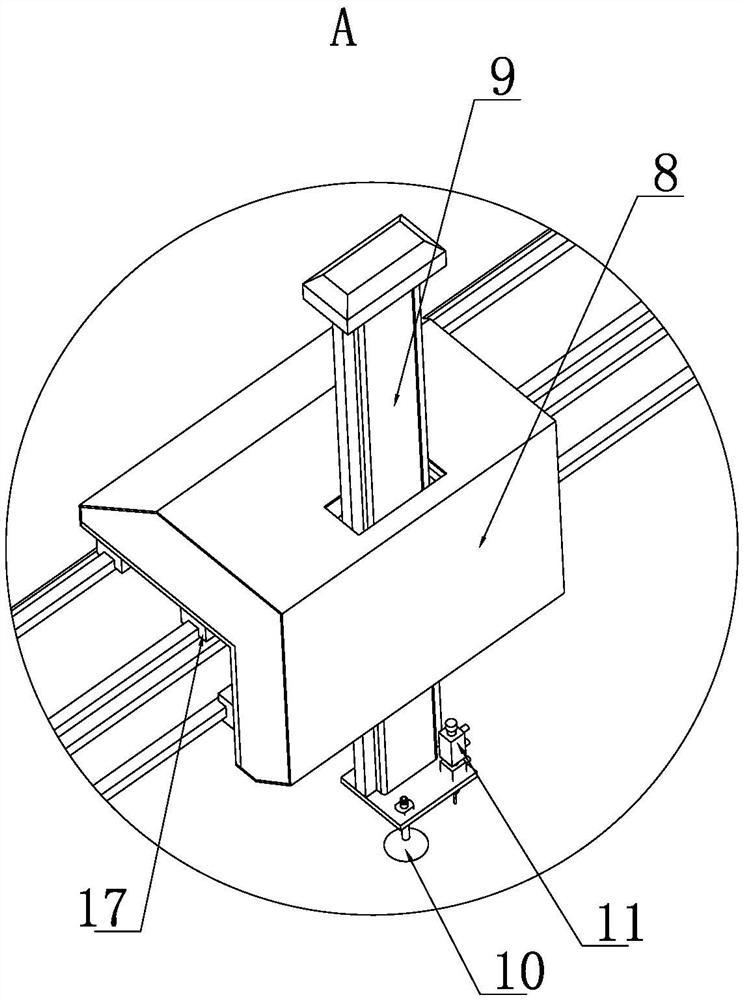

[0031] Such as Figure 1-8 As shown, it is a spraying and scribing integrated machine, which includes a console 1 and two parallel transverse beams 2. The lower side of each transverse beam 2 is arranged in sequence along the length direction with a row of supporting columns 3, and the supporting columns 3 Supported on the ground, each transverse beam 2 is provided with at least one X-axis guide rail 4 horizontally, a longitudinal beam 5 is arranged between two transverse beams 2, and the left and right ends of the longitudinal beam 5 are provided with traversing seats 6 , the two traversing seats 6 are respectively movably connected with the X-axis guide rails 4 on the corresponding transverse beams 2, and the two traversing seats 6 are respectively provided with a driving mechanism corresponding to the transverse beam 2, and at least one is longitudinally arranged on the longitudinal beam 5 A Y-axis guide rail 7, the longitudinal beam 5 is also provided with a vertically mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com