Automatic screw turning device for product assembly

A technology for screwing and screwing, which is applied in the field of automatic screwing devices for product assembly, which can solve the problems of low screwing efficiency and achieve the effects of improving work efficiency, reducing vibration feeding devices, and compact production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

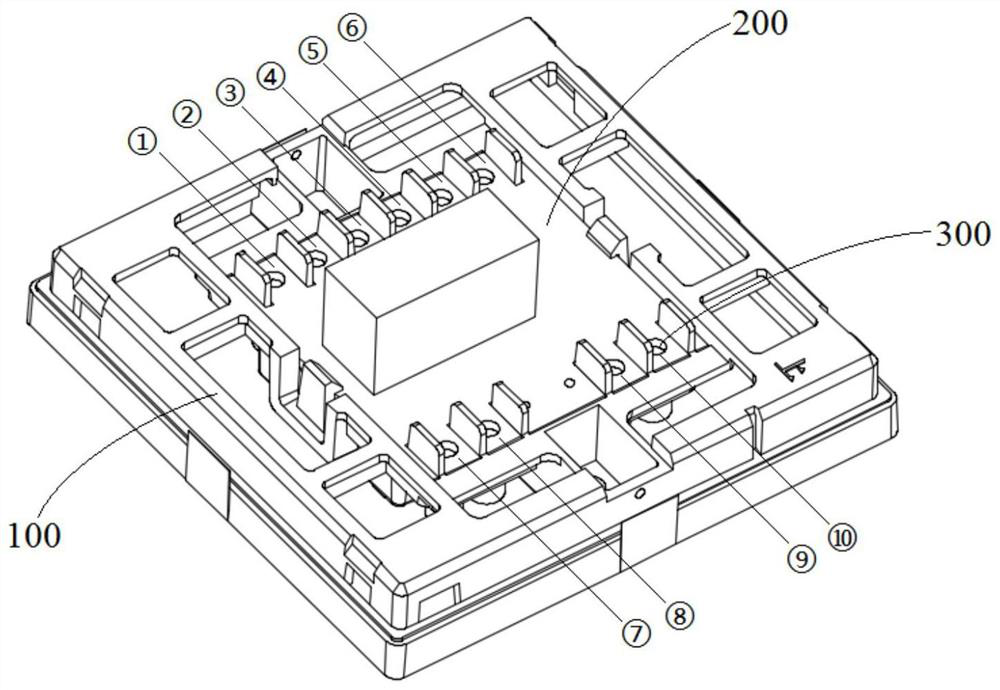

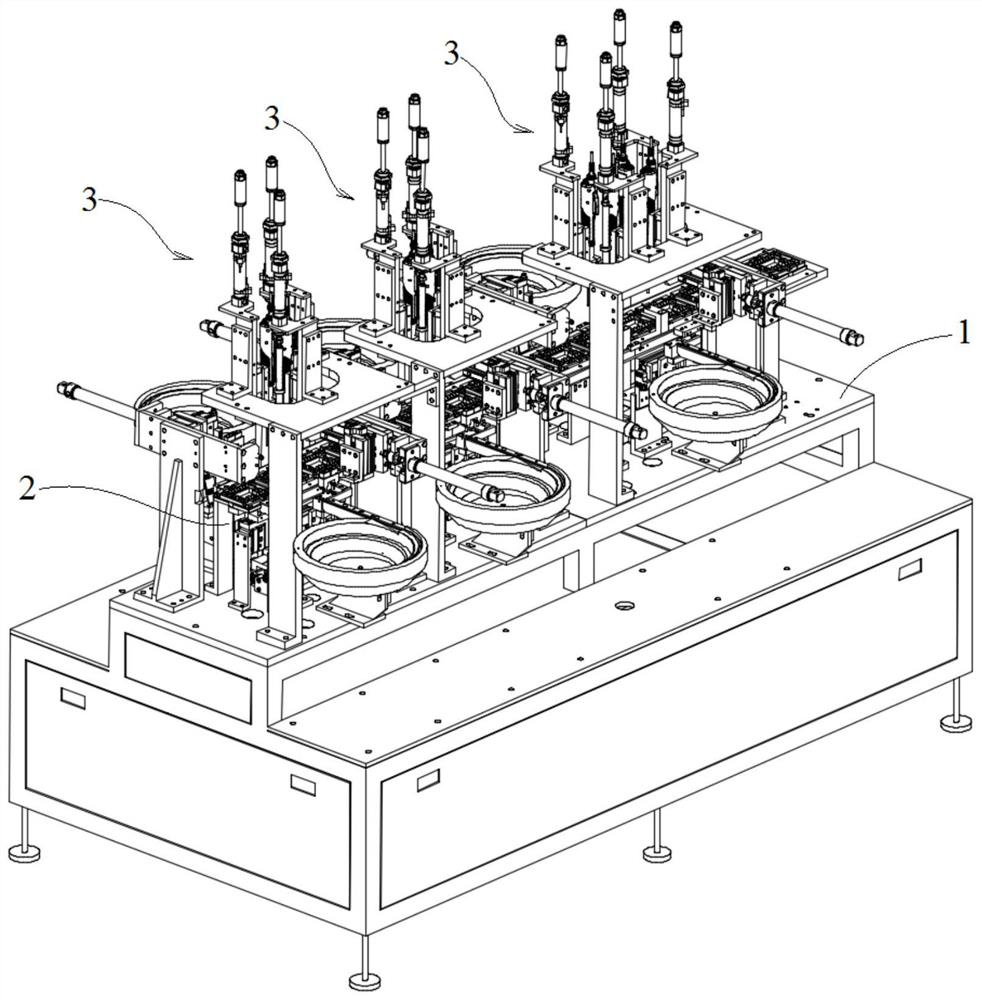

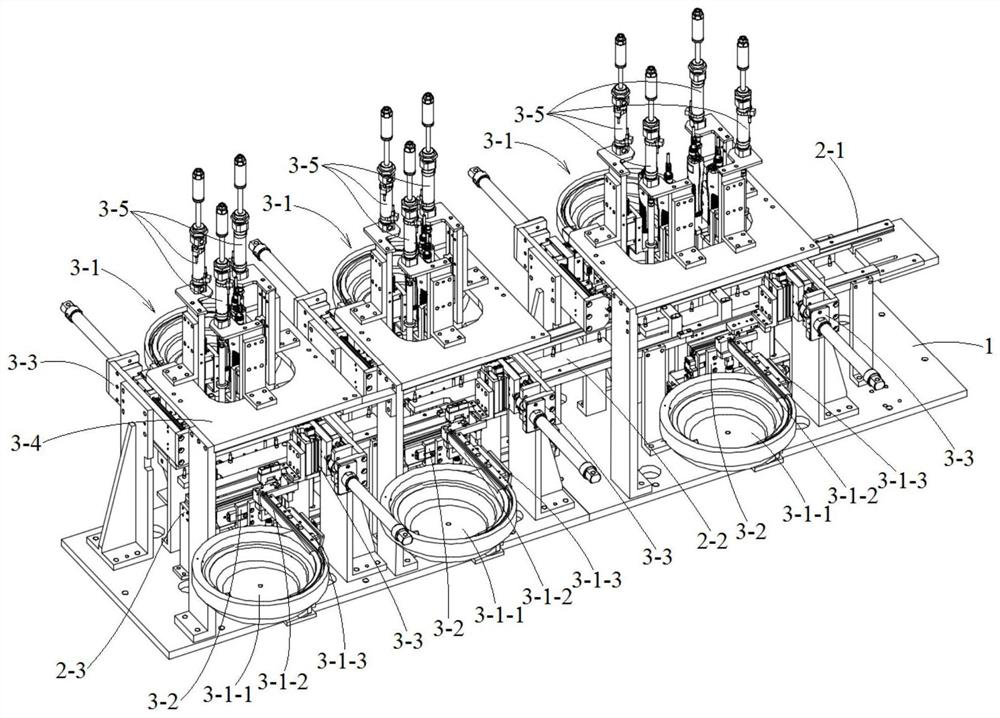

[0038] to combine figure 2 and image 3 As shown, an automatic screw screwing device for product assembly in this embodiment includes a workbench 1, a product delivery device 2 installed on the workbench 1 for driving the intermittent movement of the product to be screwed, and at least Two sets of multi-station screwing devices 3, the multi-station screwing devices 3 are arranged sequentially along the product conveying device 2, and the positions of the screw holes on the corresponding products of each multi-station screwing device 3 are staggered from each other, and the products are arranged along the product conveying device 2 Circulation, the screw loading positioning and screwing are carried out at each multi-station screwing device 3 in turn, realizing the automatic screwing assembly of multiple screws on a product. in,

[0039] Such as image 3 , Figure 6 to Figure 9 As shown, the above-mentioned multi-station screwing device 3 includes a screw feeding mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com