Rubber filtering and vulcanizing treatment process for automobile tire tube manufacturing rubber material

A technology for automobile tires and sulfur treatment, which is applied in the field of tire manufacturing, can solve the problems of sticky impurities in the filter screen, unfavorable collection, and poor filtering effect, so as to improve the filtering efficiency and filtering effect, improve the filtering effect and filtering efficiency, avoid The effect of re-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are easy to understand, and the present invention is further illustrated in connection with the specific illustration. It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other.

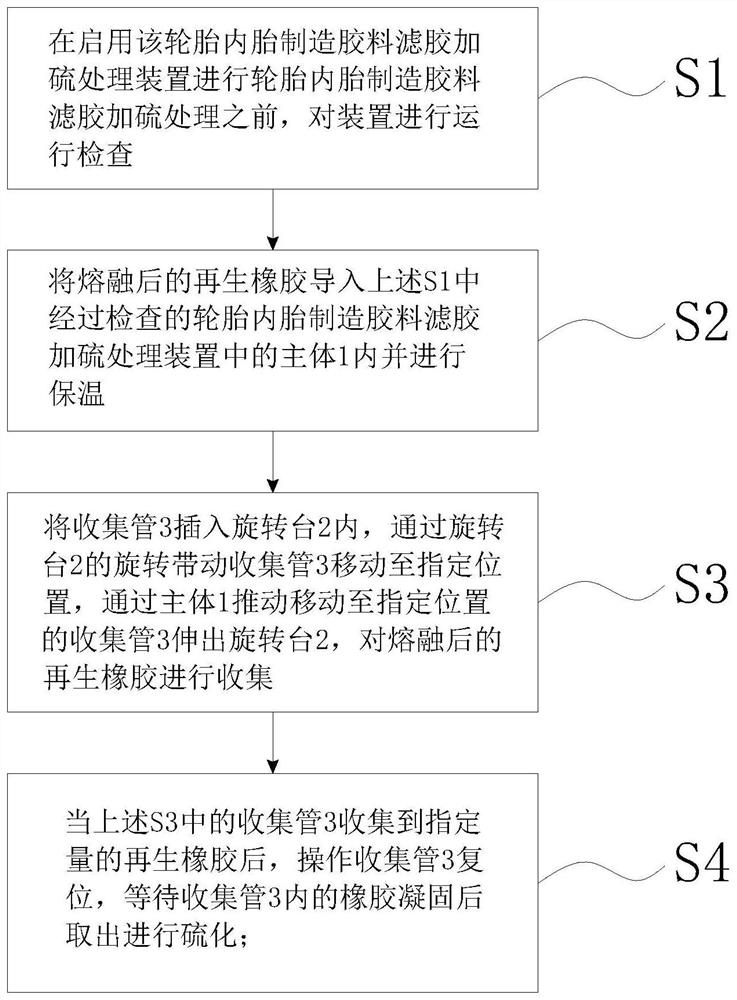

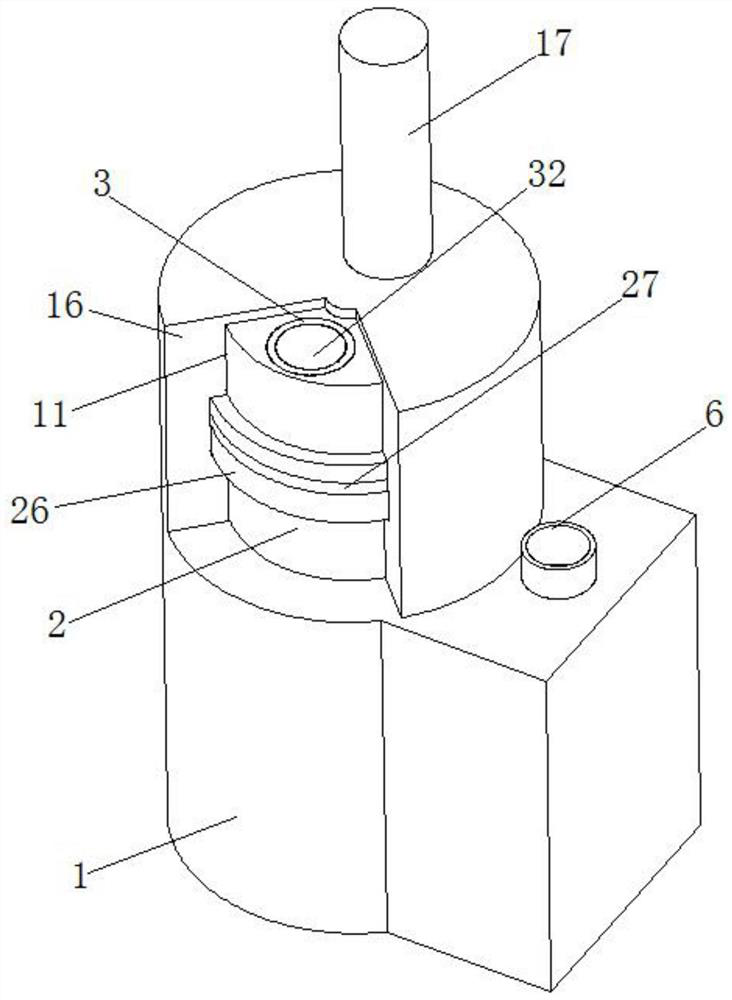

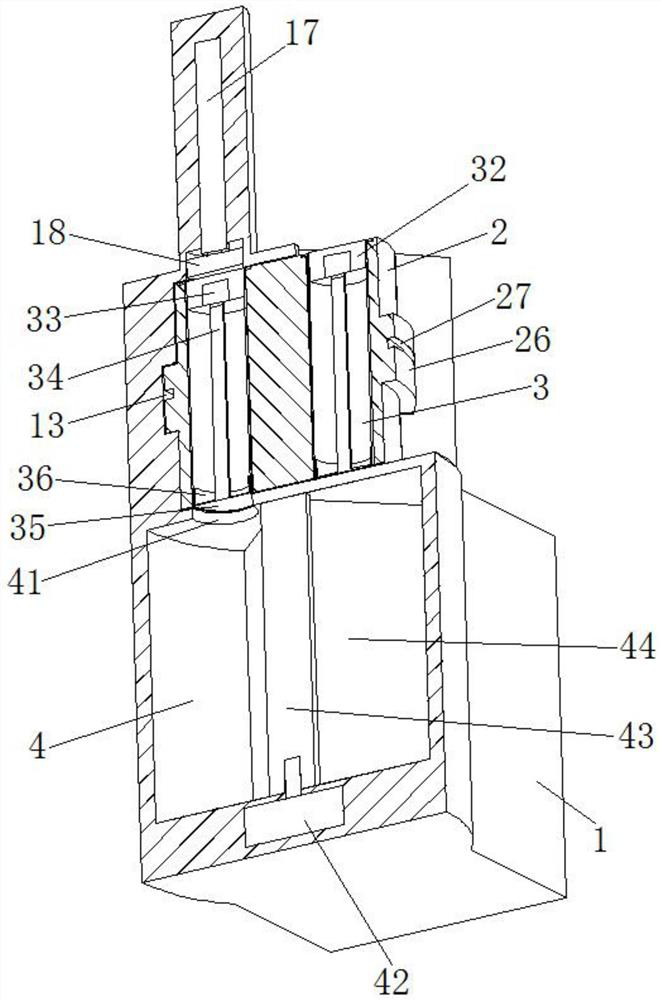

[0034] like Figure 1 to 8 As shown, an automotive tire inner tube manufacturing process is used, which uses a tire inner tube manufacturing rubber filter, the tire inner tube manufacturing rubber filter, and the sulfur treatment device including the main body 1. , The rotary table 2 and the collection tube 3 are used in the above-mentioned tire inner tube manufacturing rubber powder and the sulfur-free treatment device to produce a tire inner tube, and the specific method is as follows:

[0035] S1, device inspection: The device performs an inspection before the tire inner tube manufactu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com