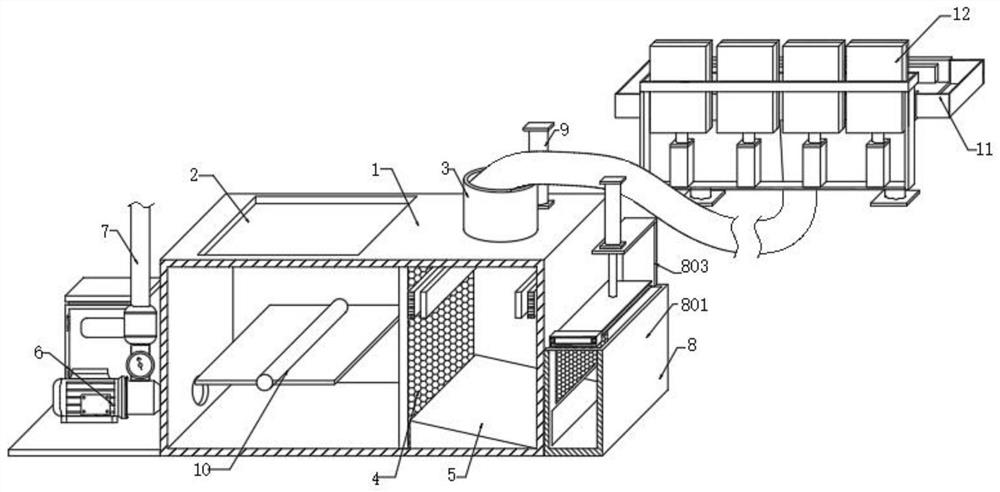

Metal cutting fluid recycling and circulating flow purification equipment

A technology of metal cutting fluid and circulating flow, which is applied in the direction of metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc. It can solve the problems of reducing the operating space of cutting devices, retrieving cutting fluid is cumbersome, and the liquid collecting end cannot be matched. , to achieve the effect of convenient recycling, preventing splashing and accelerating recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] see Figure 7-Figure 8 , in the embodiment of the present invention, the feeding assembly 11 includes a collecting tank 1101, the two sides of the collecting tank 1101 are sleeved with telescopic grooves 1102, the inner walls of the collecting tank 1101 are fixed with magnets 1103 on both sides, and the lower end of the collecting tank 1101 is fixed with a The connecting pipe 1104 connected to the input end of the liquid inlet pipe 3, the second chute 1105 is fixed at the lower end of the collecting tank 1101, and the inner cavity of the second chute 1105 is socketed with a second slider 1106, and the second slider 1106 is lowered. The end face is fixed with a rotating shaft 1107, the rotating end of the rotating shaft 1107 is fixed with a third cylinder 1108, the lower end of the third cylinder 1108 is fixed with a backing plate 1109, and the telescopic groove 1102 can be pulled out from both sides of the collecting tank 1101 to increase the amount of aggregate. The di...

Embodiment 2

[0036] see Figure 9-Figure 11 , and the difference from Embodiment 1 is that: the splash-proof assembly 12 includes an annular plate 1201 fixed on the upper end of the collecting tank 1101, a mounting plate 1202 is fixed on the lower end of one side of the annular plate 1201, and several fourth Cylinder 1203, the upper end of several fourth cylinders 1203 is fixed with a shielding plate 1204 socketed with the inner cavity of the annular plate 1201, the surface of the shielding plate 1204 is fixed with a sponge 1205, the upper end of the shielding plate 1204 is fixed with an infrared sensor module 1206, and the annular plate 1201 Two connection blocks 1207 are fixed on the upper end, and a sleeve rod 1208 is fixed between the two connection blocks 1207. A shovel plate 1209 is sleeved on the surface of the sleeve rod 1208. A torsion spring 1210 is fixed between the shovel plate 1209 and the connection block 1207. The shovel plate 1209 can always keep extruding and sticking to t...

Embodiment 3

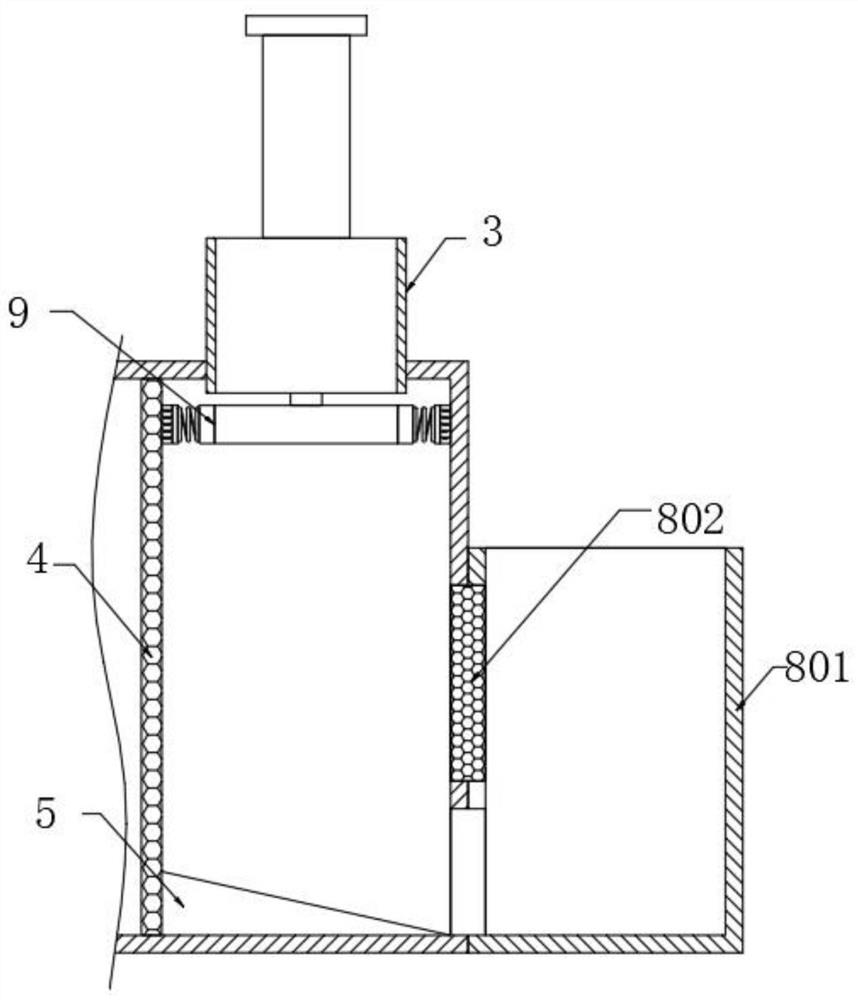

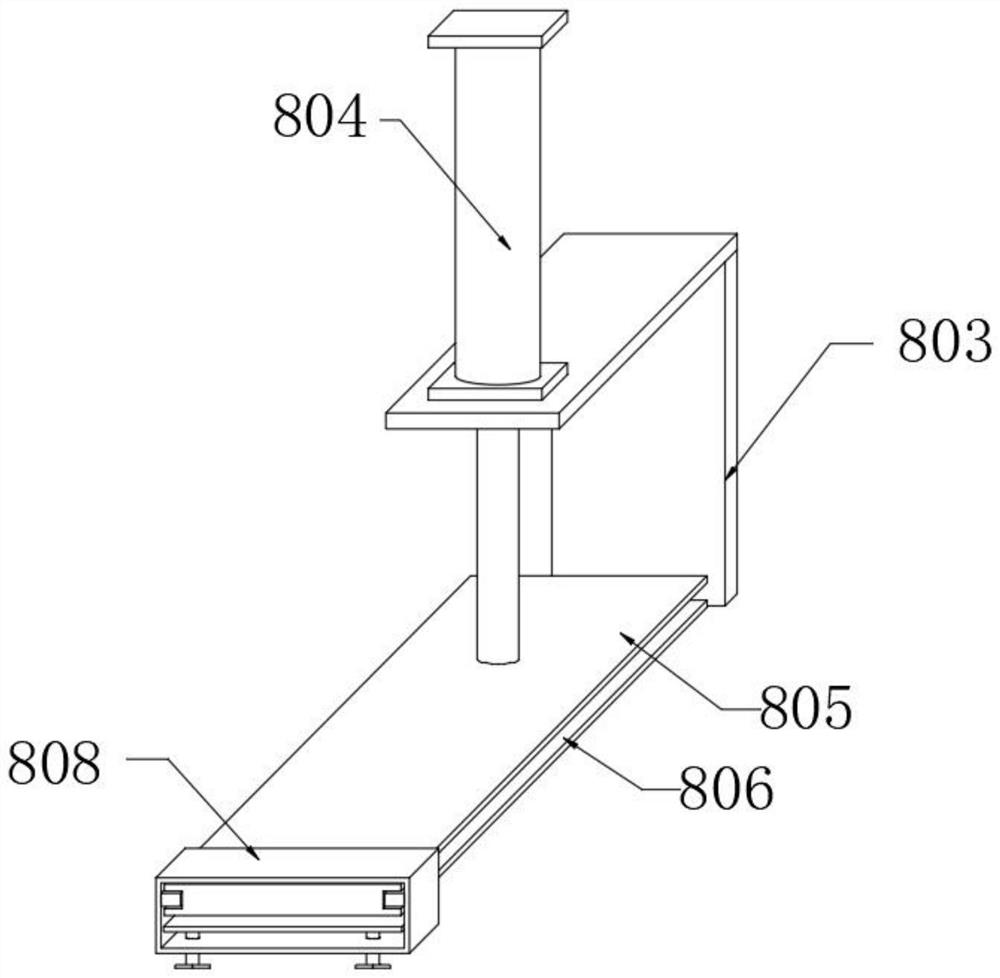

[0038] see Figure 2-Figure 4 The difference from Example 1 is that the purification assembly 8 includes: a dirt storage tank 801 fixed on the surface of the box body 1, a filter screen 802 is embedded between the dirt storage box 801 and the box body 1; The support plate 803 on the upper end surface of 801, the top of the support plate 803 is fitted with a first cylinder 804, the output end below the first cylinder 804 is fixed with an electromagnetic plate 805, the two sides of the electromagnetic plate 805 are provided with a first chute 806, the first slide The first slider 807 is inserted into the cavity of the groove 806, and the surface of the two first sliders 807 is fixed with a sleeve plate 808 socketed with the electromagnetic plate 805. The lower end of the sleeve plate 808 is threaded with a bolt 809, and the bolt 809 is close to the sleeve. One end of the centerline of the plate 808 is rotated by a rotating member to install a scraper 810, and a through groove is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com