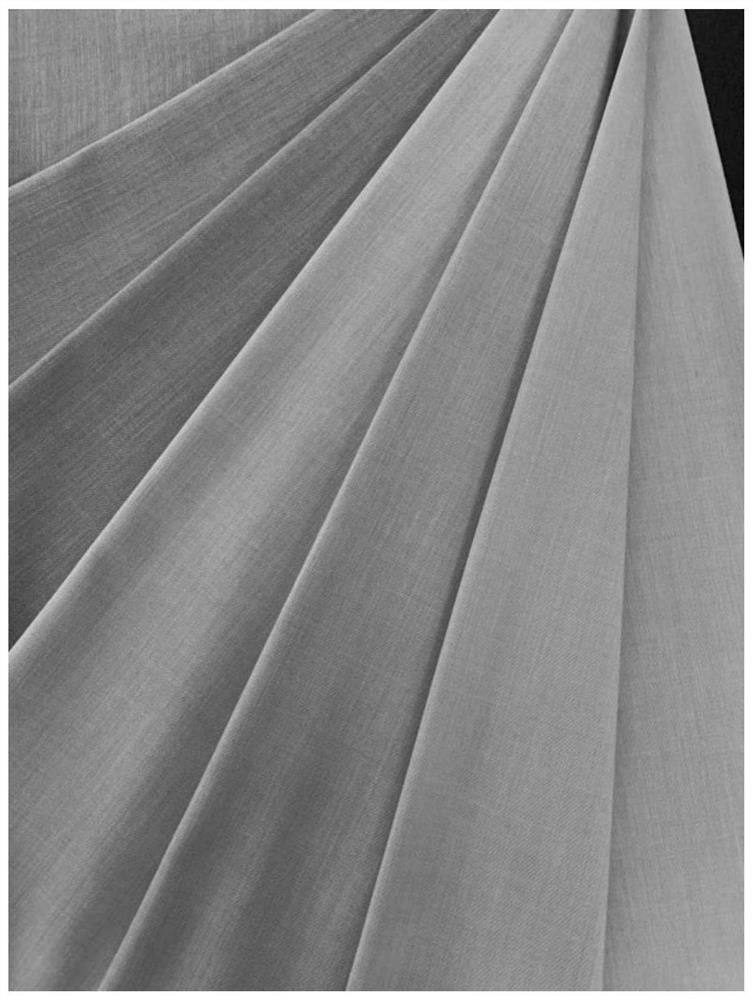

Anti-pilling wool-like comfortable fabric and preparation method thereof

An anti-pilling and wool-like technology, applied in the field of wool-like comfortable fabrics and their preparation, can solve the problems of easy pilling, washing resistance, poor wear resistance, easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

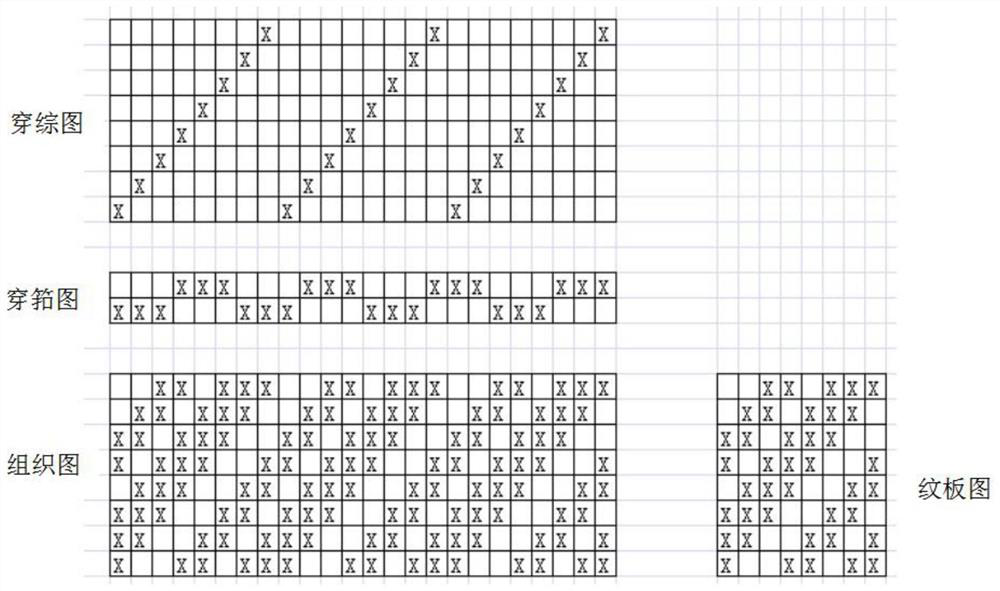

Image

Examples

Embodiment 1

[0046] The wool-like comfortable fabric specifications are: warp density 630 threads / 10cm, weft density 420 threads / 10cm, gram weight 300g / m.

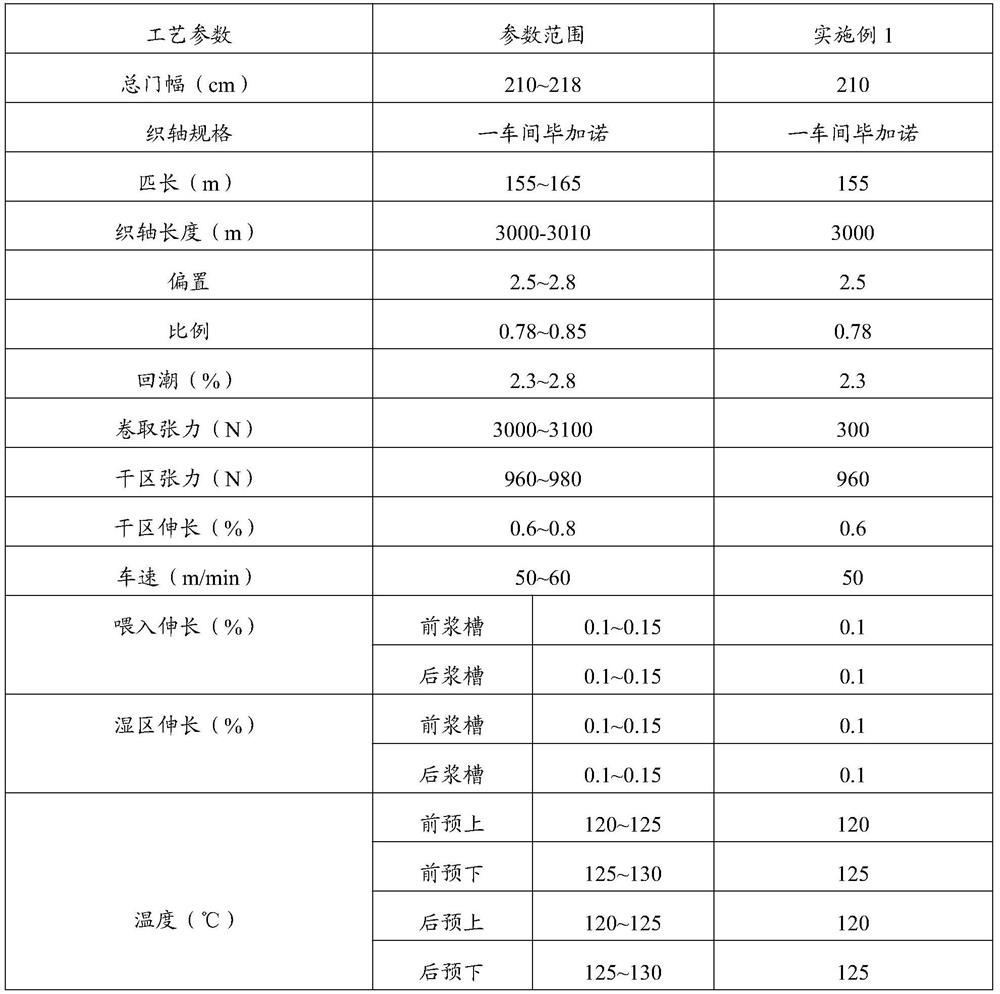

[0047] making process:

[0048] Spinning: Using 60% polyester fiber, 32% viscose fiber and 8% spandex fiber as raw materials, the warp and weft yarns are prepared by Siro compact spinning; the length of the single fiber in the warp is 58-65mm, and the fineness of the single fiber is The length of the single fiber in the weft is 1.6D, the length of the single fiber in the weft is 75-80mm, the fineness of the single fiber is 2.3D, and the twist of the warp and weft is 1300T / m;

[0049] Steaming treatment: steaming the warp and weft at 68°C for 2 hours;

[0050] Warping in batches: the steamed warp yarns are tensioned and parallel wound on the warping beam; the warping speed is 300m / min, the total air pressure is 0.7MPa, and the yarn pressing air pressure is 0.4MPa;

[0051] Sizing: the warp beam of the above-mentioned winding warp is w...

Embodiment 2

[0060] The wool-like comfortable fabric specifications are: warp density 640 threads / 10cm, weft density 430 threads / 10cm, gram weight 280g / m.

[0061] making process:

[0062] Spinning: Using 59% polyester fiber, 32% viscose fiber and 9% spandex fiber as raw materials, the warp and weft yarns are prepared by Siro compact spinning; the length of the single fiber in the warp is 58-65mm, and the fineness of the single fiber is The length of the single fiber in the weft is 1.6D, the length of the single fiber in the weft is 75-80mm, the fineness of the single fiber is 2.3D, and the twist of the warp and weft is 1350T / m;

[0063] All the other steps are the same as in Example 1.

Embodiment 3

[0065] The specifications of wool-like comfortable fabric are: warp density 650 threads / 10cm, weft density 440 threads / 10cm, and weight 310g / m.

[0066] making process:

[0067] Spinning: Using 62% polyester fiber, 30% viscose fiber and 8% spandex fiber as raw materials, warp and weft are prepared by Siro compact spinning; the length of single fiber in warp is 58-65mm, and the fineness of single fiber The length of the single fiber in the weft is 1.6D, the length of the single fiber in the weft is 75-80mm, the fineness of the single fiber is 2.3D, and the twist of the warp and weft is 1380T / m;

[0068] All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com