Cloth dyeing mechanism for textile production

A fabric and feeding tube technology, applied in textile processing machine accessories, textile material processing, textile material carrier processing, etc., can solve the problems of unstable chemical concentration in pad dyeing tank, different dye liquor concentration, high additive concentration, etc. To achieve the effect of speeding up the mixing of dye liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

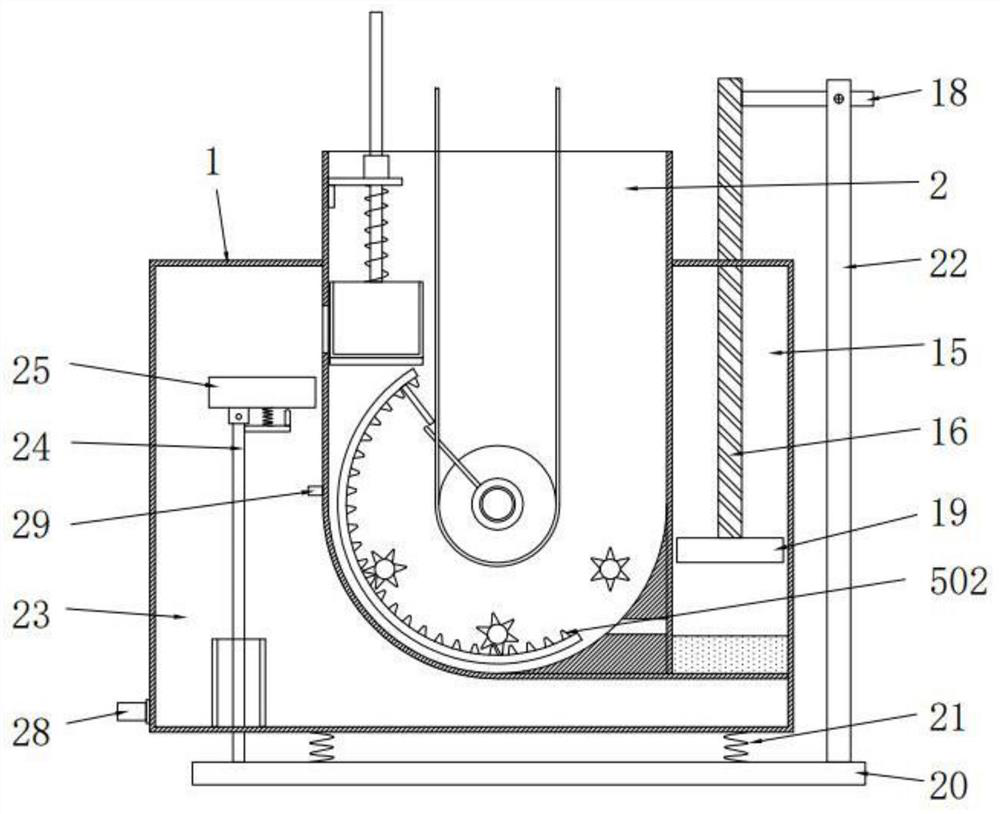

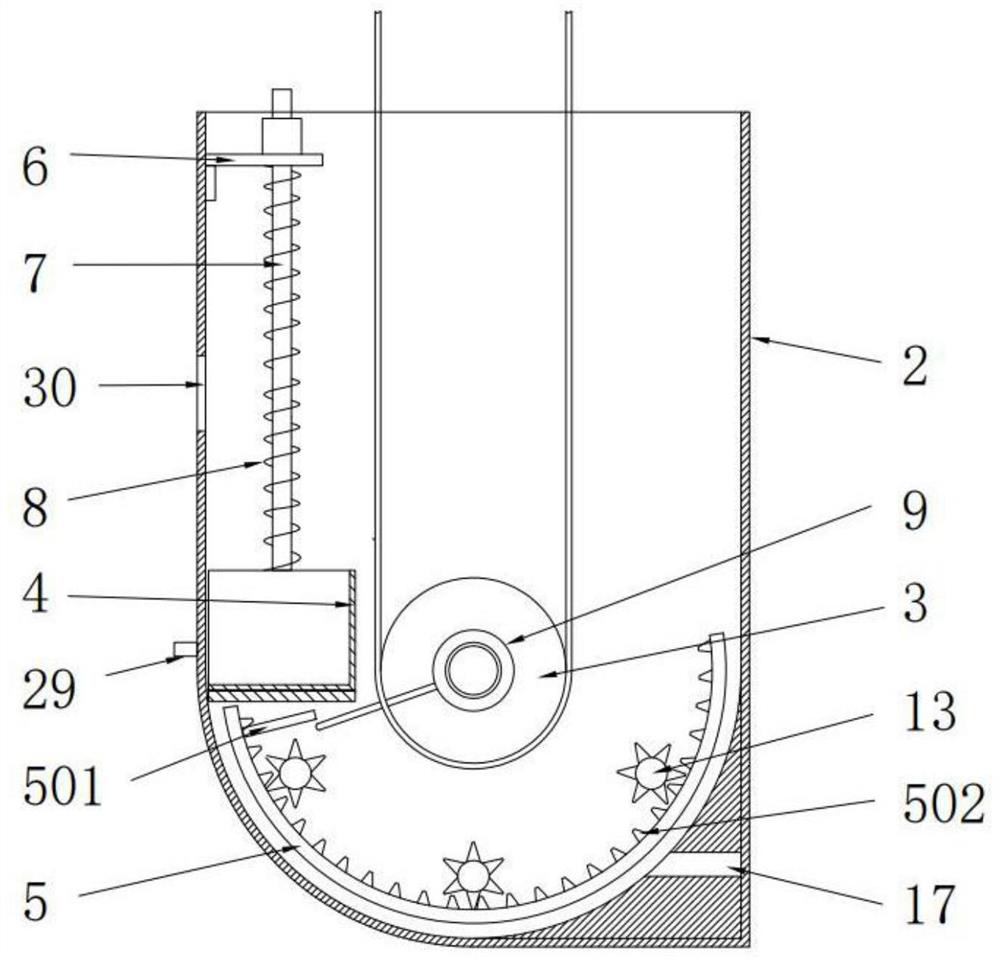

[0029] See Figure 1-5 A fabric staining mechanism for textile production, including the outer casing 1, the upper side of the outer casing 1, and the bottom end of the soaking groove 2 is u-shaped, and the inside of the immersion groove 2 is provided with a guide roller 3. , Movable seat 4, movable plate 5 and fixed plate 6;

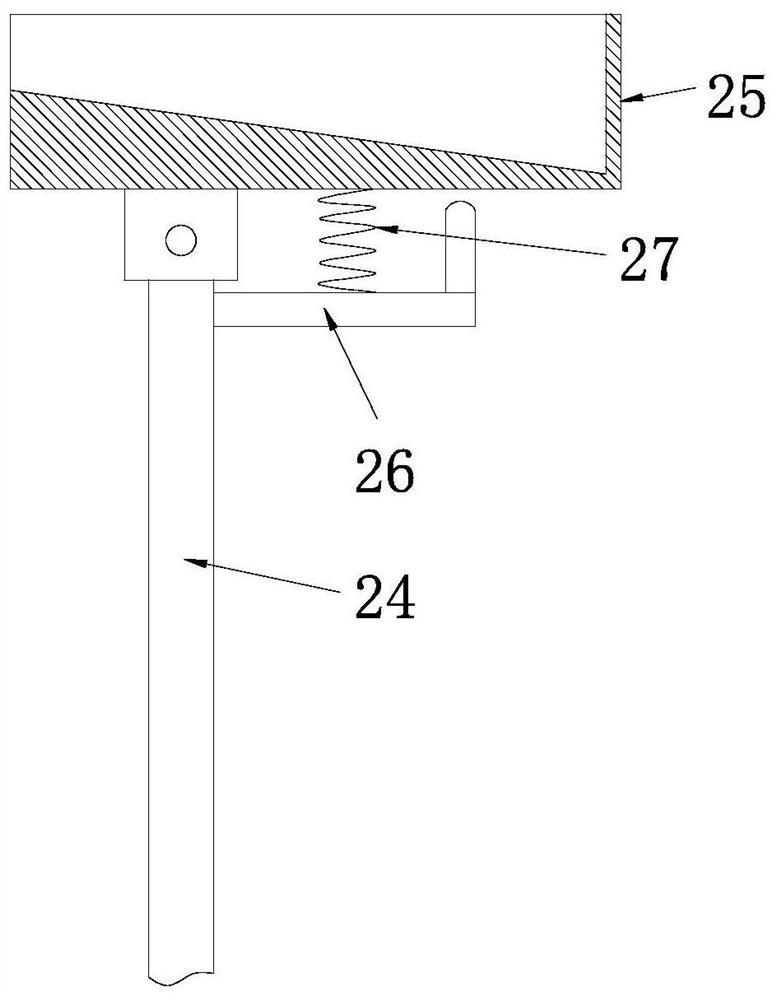

[0030] The fixing plate 6 is disposed on the upper end of the immersion groove 2, and the movable seat 4 is located on the lower side of the fixing plate 6, and the upper end of the movable seat 4 is provided with a guide bar 7, the position and the number of the guide rod 7 corresponds to the fixed plate 6. And the guide rod 7 is slidked on the fixing plate 6, and the movable seat 4 is also elastically coupled to the fixing plate 6 by the connecting spring 8, and the fixing plate 6 is in shape, and one end of the fixing plate 6 is fixed to the immersion groove 2, the movable seat 4 is a rectangular shape, and the top of the movable seat 4 is an open structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com