Mine dedusting and cooling system

A mine and dust concentration technology, which is applied in mine/tunnel ventilation, dust prevention, mining equipment, etc., can solve the problems of water pollution and poor effect in the mine, and achieve no pollution to the underground environment, strong mobility, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

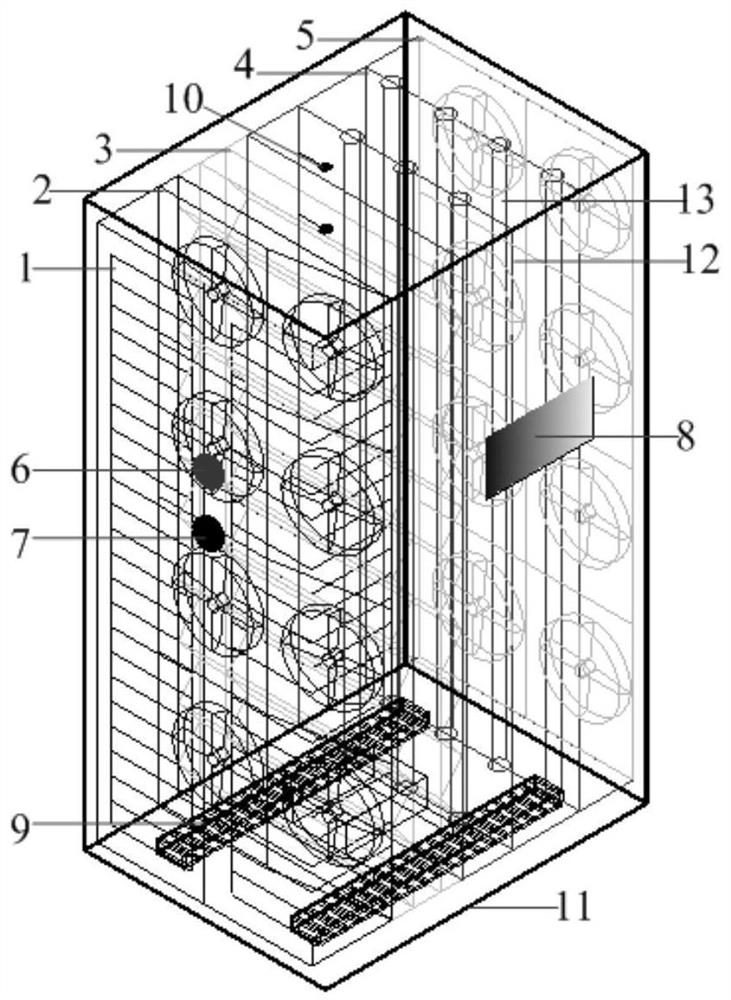

[0033] The mine dust removal and cooling system of this application is suitable for mobile dust removal and cooling of coal mining working faces in mines. The mine dust removal and cooling system of this application integrates dust removal and cooling. When mine dust is generated during the production process of the underground coal mining face and affects the mine operating environment and the health of underground workers, it creates a healthy and green working environment for the underground.

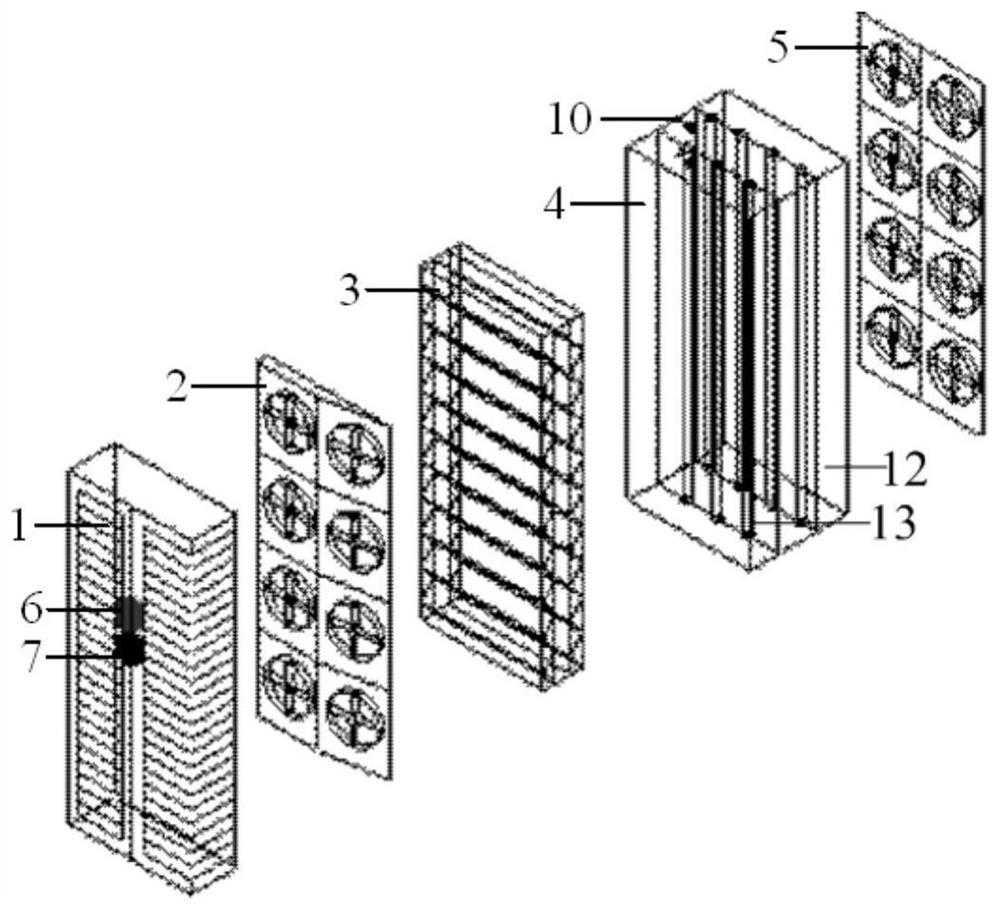

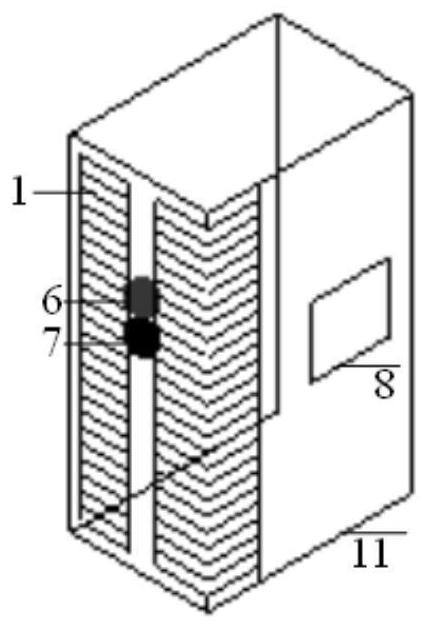

[0034] figure 1 It is a schematic structural diagram of the mine dust removal and cooling system for this application, figure 2 For the explosion diagram of the mine dust removal and cooling system for this application, combined with figure 1 and figure 2 As shown, the mine dust removal and cooling system includes a casing 11 and a control panel 8 disposed on the casing 11, wherein the casing 11 includes an air inlet side and an exhaust side that are oppositely arranged.

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com