Anti-leakage and anti-winding debuggable tail shaft rear sealing device

An anti-leakage and anti-winding technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of lubricating oil backflow and damage to the machine, so as to avoid the entanglement and damage of debris, improve the anti-leakage shape, and increase the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

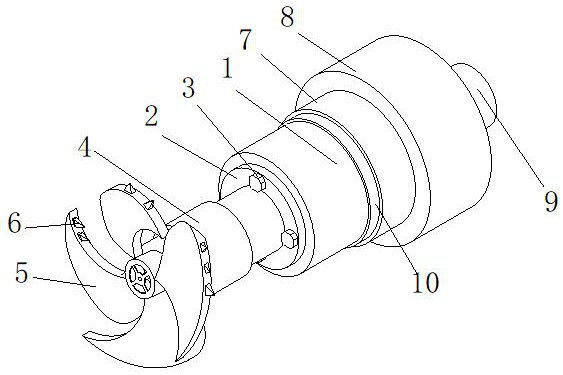

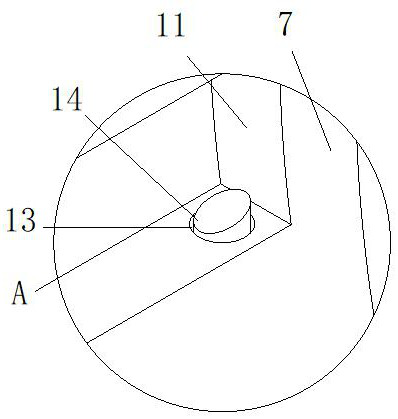

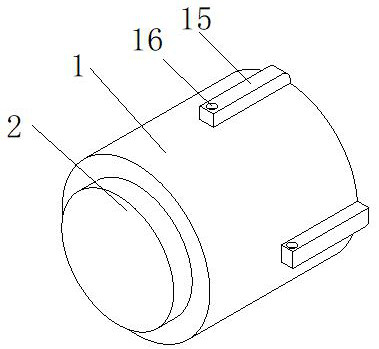

[0031] see Figure 1-6, the present invention provides a technical solution: an anti-leakage and anti-winding adjustable tail shaft rear sealing device includes a tail shaft body 1, the front surface of the tail shaft body 1 is provided with a wear-resistant sleeve 2, and the front surface of the wear-resistant sleeve 2 is Bolt 3 is threadedly connected, and wear-resistant sleeve 2 is connected with tail shaft body 1 through bolt 3. The front surface of wear-resistant sleeve 2 is fixedly connected with connecting shaft 4, and the front end of connecting shaft 4 is connected with propeller 5 in rotation. The outer wall is fixedly connected with a sharp cutting board 6. When using the device, when the propeller 5 rotates, the cutting board 6 is driven to rotate. Through the rotation of the cutting board 6, the sundries attached to the propeller 5 can be cut and pulverized, thereby Prevent the propeller 5 from being entangled with debris, thereby avoiding the damage of the propel...

Embodiment 2

[0034] Example two; see Figure 1-6 , on the basis of Embodiment 1, the rear surface of the sealing block 8 is provided with a threaded hole 22, and the inside of the sealing block 8 is provided with an anti-leakage device. Inside, the front and rear ends of the threaded rod 18 run through the sealing block 8, the front end of the threaded rod 18 is fixedly connected with a piston 19, and the piston 19 is slidably connected to the inside of the sealing block 8, the piston 19 has a sealing effect, and the rear end of the threaded rod 18 is in contact with the rotating The plug 9 is fixedly connected, and the inner front side of the sealing block 8 is provided with a communication groove 20 communicating with the inside of the O-ring 7. The inside of the O-ring 7 is provided with a waterproof air bag 21 communicating with the communication groove 20. The waterproof air bag 21 and the oil storage ring 12 contacts.

[0035] Further, when using the device, the rotation of the plug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com