Modularized stern room and rudder control transmission mechanism

A technology of transmission mechanism and tail cabin, which is applied to projectiles, self-propelled projectiles, offensive equipment, etc., can solve the problems of difficult installation and debugging of instruments, unfavorable modular assembly of arrow bodies, etc., and achieve the effect of simple and compact mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

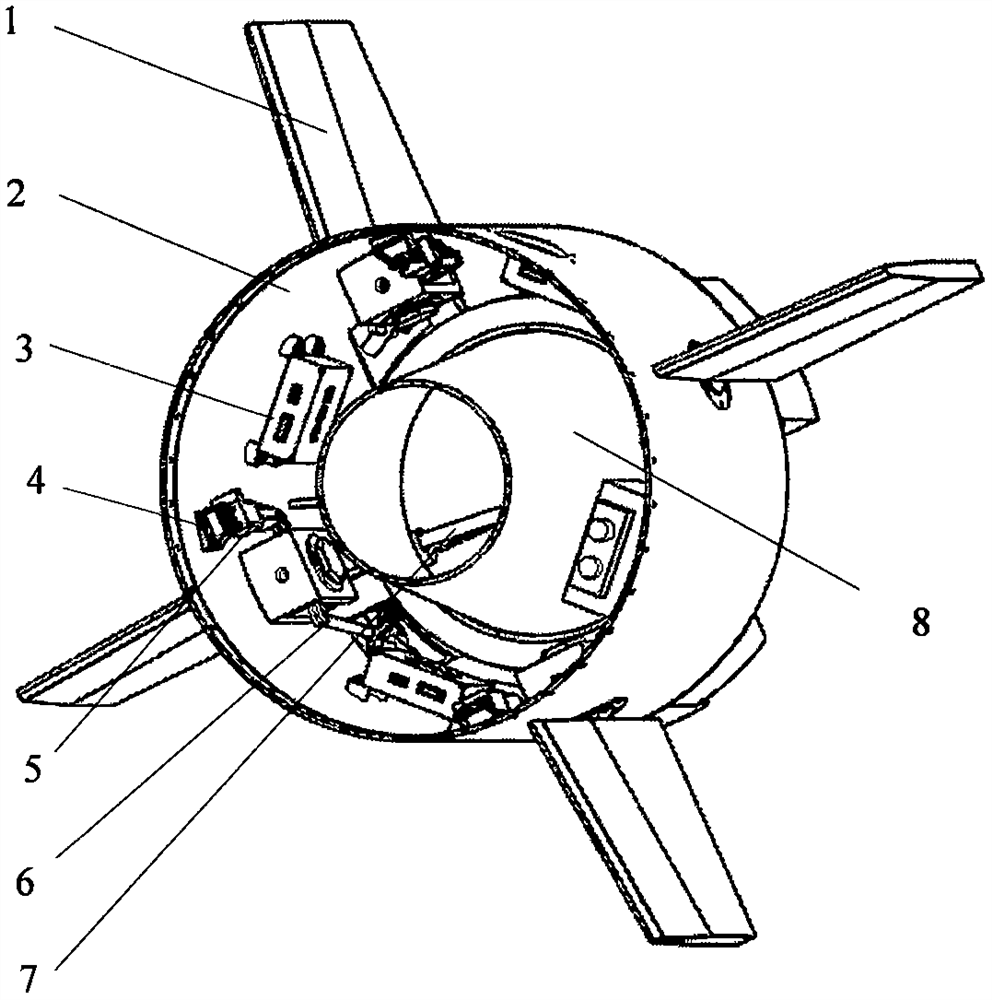

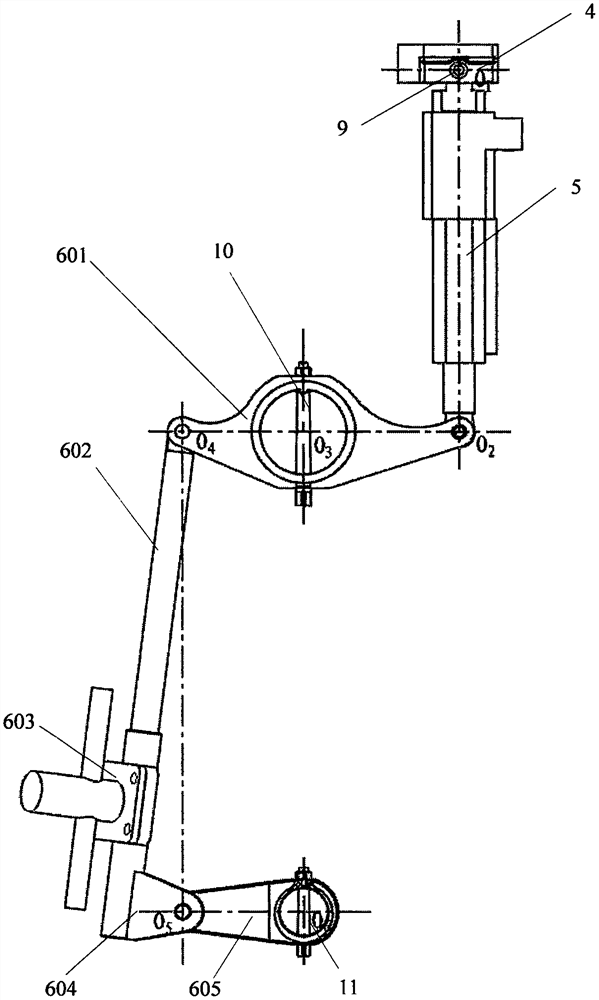

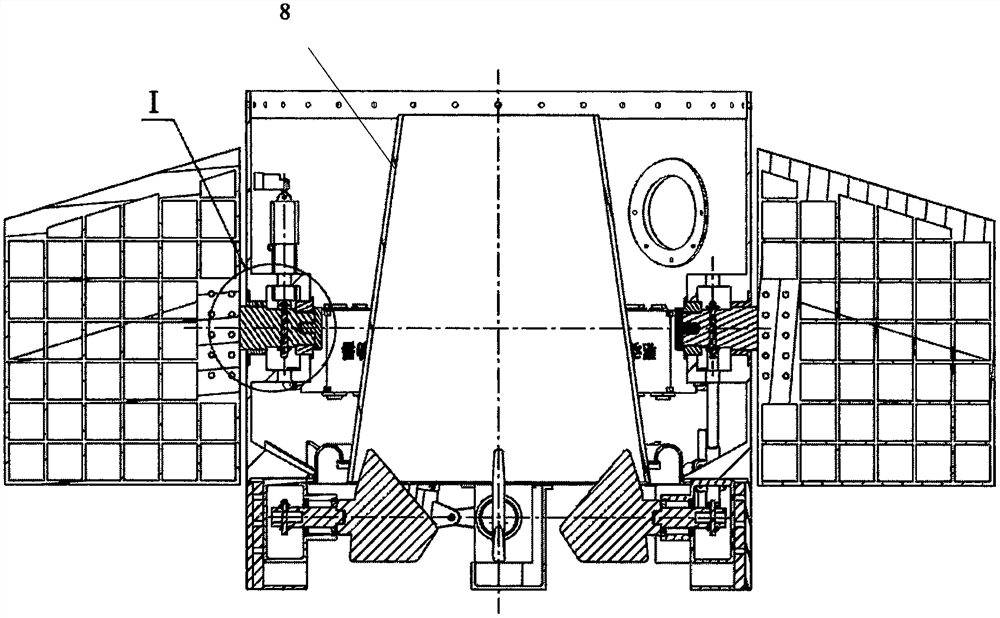

[0021] Such as Figure 1-6 As shown, the present invention provides a modular stern compartment and rudder control transmission mechanism, which mainly includes a stern compartment housing 2, a controller 3, a steering gear mounting seat 4, an air rudder 1, a steering gear 5, and a connecting rod assembly 6 , gas rudder 7, etc.;

[0022] The controller 3 is fixedly connected to the instrument installation boss 203 of the tail compartment shell 2, and the steering gear mounting seat 4 is fixedly connected to the steering gear installation boss 201 of the tail compartment shell 2;

[0023] The output mode of the steering gear 5 is a linear output, the steering gear 5 is hinged on the steering gear mount 4 through the pin shaft 9, and can swing through the pin shaft; the output shaft of the steering gear 5 and the connecting rod assembly are hinged through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com