Door plank modular flexible assembly line and assembly method of assembly line

A modular and assembly line technology, applied in transportation and packaging, motor vehicles, etc., can solve problems such as low production efficiency, easy loosening of screws, increased energy consumption, etc., and achieve high production efficiency, good safety, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

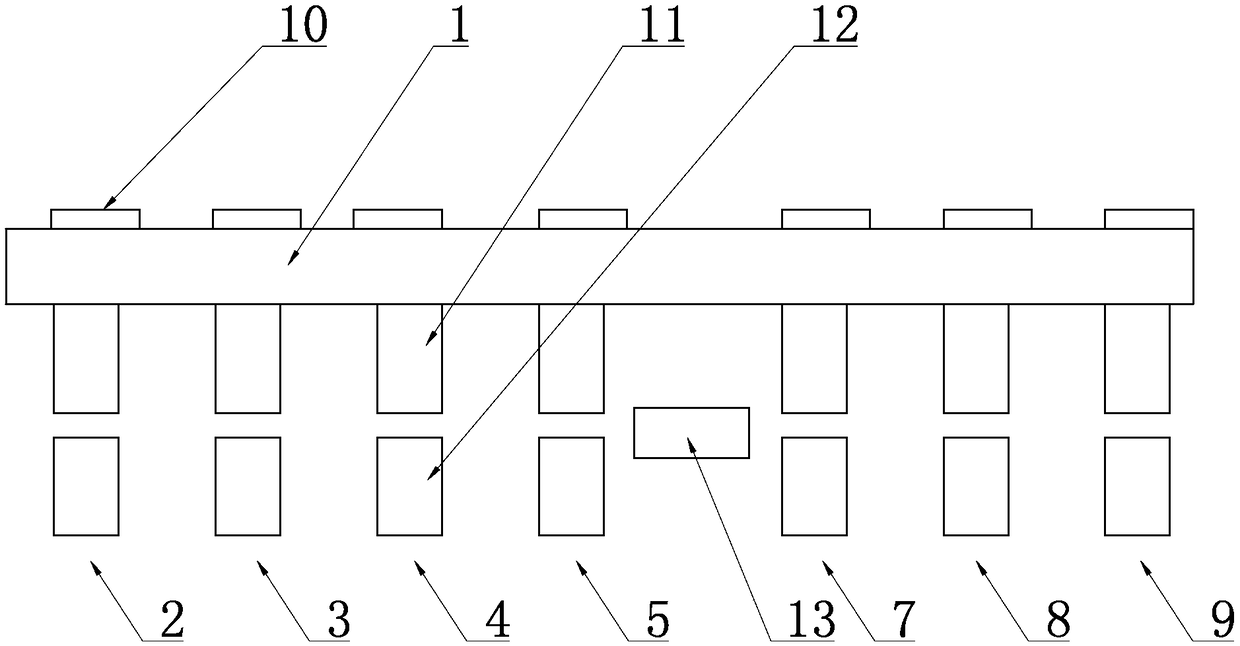

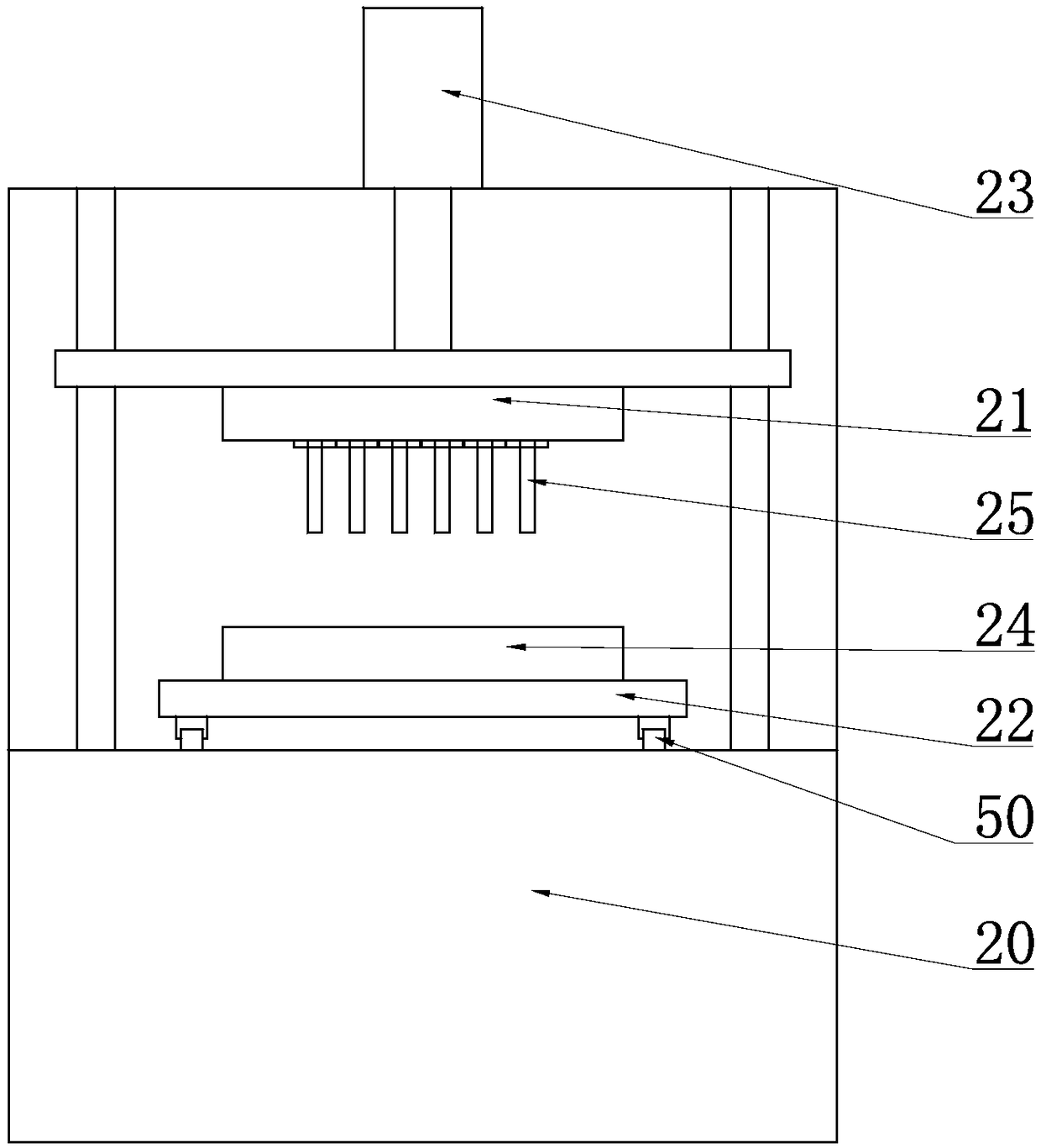

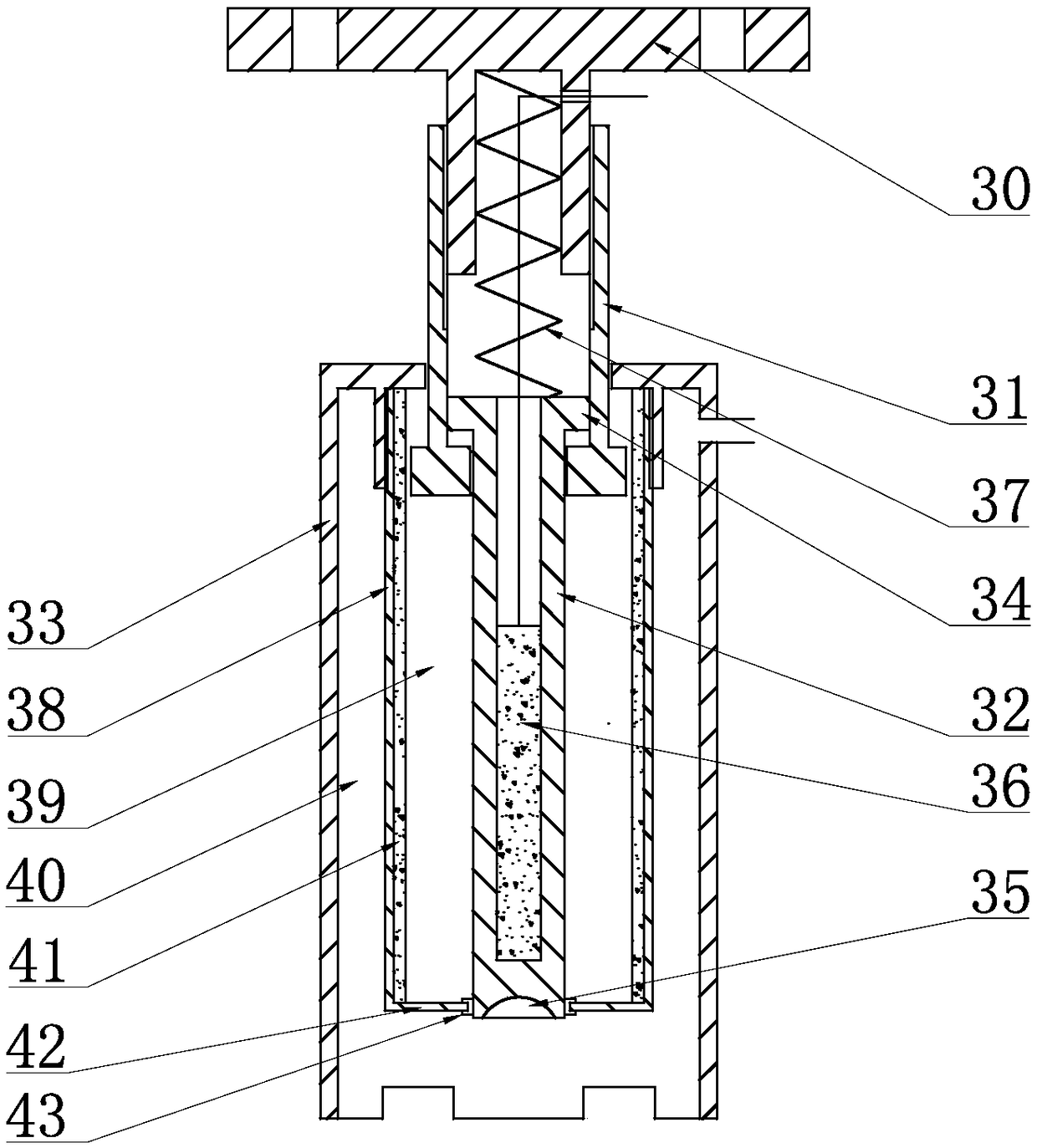

[0030] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-3 :

[0031] A modular flexible assembly line for door panels, including a conveying line 1, characterized in that: along the conveying direction of the conveying line 1, a first installation station 2 for installing an upper decorative panel and a second installation station for installing a liner are arranged in sequence. Station 3, the third installation station for installing decorative strips 4, the welding station for hot riveting welding 5, the fourth installation station for speaker cover installation 7, the fifth installation station for installing sound insulation pads Position 8 and inspection station 9, each station is equipped with an installation guidance device 10 correspondingly, the installation guidance device 10 includes a TV and a U disk, the U disk is inserted into the port of the TV, and the installation process is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com