Intercooling device of electrolysis device

A technology of cooling device and electrolysis device, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of affecting current efficiency, high unit consumption, stray current, etc., and achieve improved current efficiency, efficient cooling effect, and uniform liquid temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in detail.

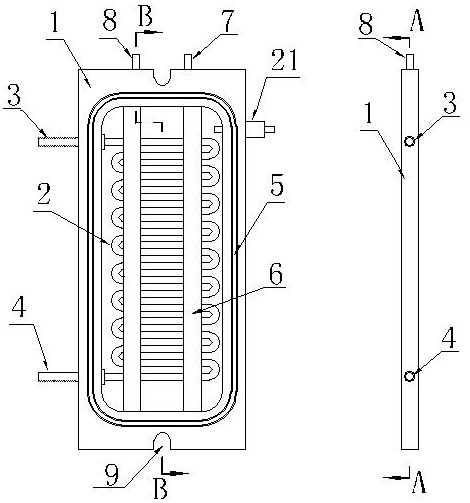

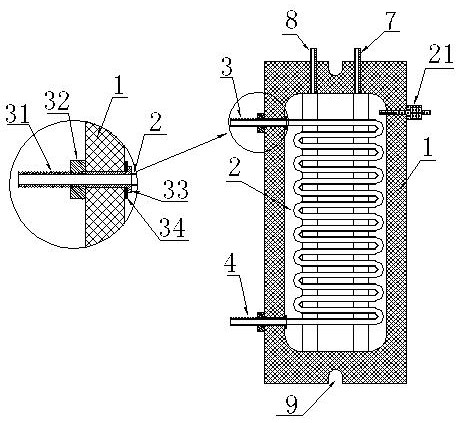

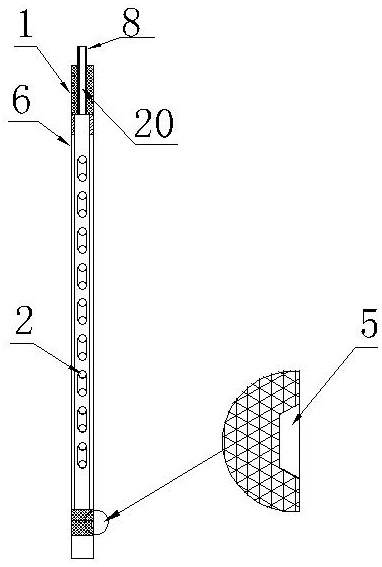

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 The intercooling device of a kind of electrolyzer shown in each electrolyzer comprises a plurality of electrolytic units connected in series and end face pole plate 13, separating plate 14, pressing plate 15, tension bolt 16, and each electrolyzer comprises multiple again The cathode plate 11 and the anode plate 12 connected in parallel are characterized in that an intermediate cooling device is provided between two adjacent electrolytic units or in a single electrolytic unit, and the intermediate cooling device mainly includes a plate frame 1, a titanium disc Pipe 2, cooling water inlet and outlet pipes 3, 4, exhaust pipes 7, 8, temperature probe 21; a sealing groove 5 is engraved on the outer edge of one side of the frame body of the plate frame 1, and a sealing groove 5 is arranged in the sealing groove 5 Pad 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com